OPERATION | ||

|

|

|

OUTPUT LIMITATIONS

The maximum output current as specified in the instal- lation section of this manual is derated in several situ- ations; alternate AC Wave Forms, elevated AC Frequencies and 115V input.

• Alternate AC Wave Forms (See Set Up Menu)¹

Square 200 amps max. output Sinusoidal 150 amps max. output Triangular 120 amps max output

• Elevated AC Frequencies¹

Above 85Hz (AC output) the square wave out- put is limited to 170 amps. Elevated AC Frequencies do not effect the output of Sinusoidal and Triangular Waveforms.

• 115V Operation 150 A TIG Mode

110 A Stick Soft mode

100 A Stick Crisp Mode

These derated values have been programmed into the Invertec

¹AC/DC model only

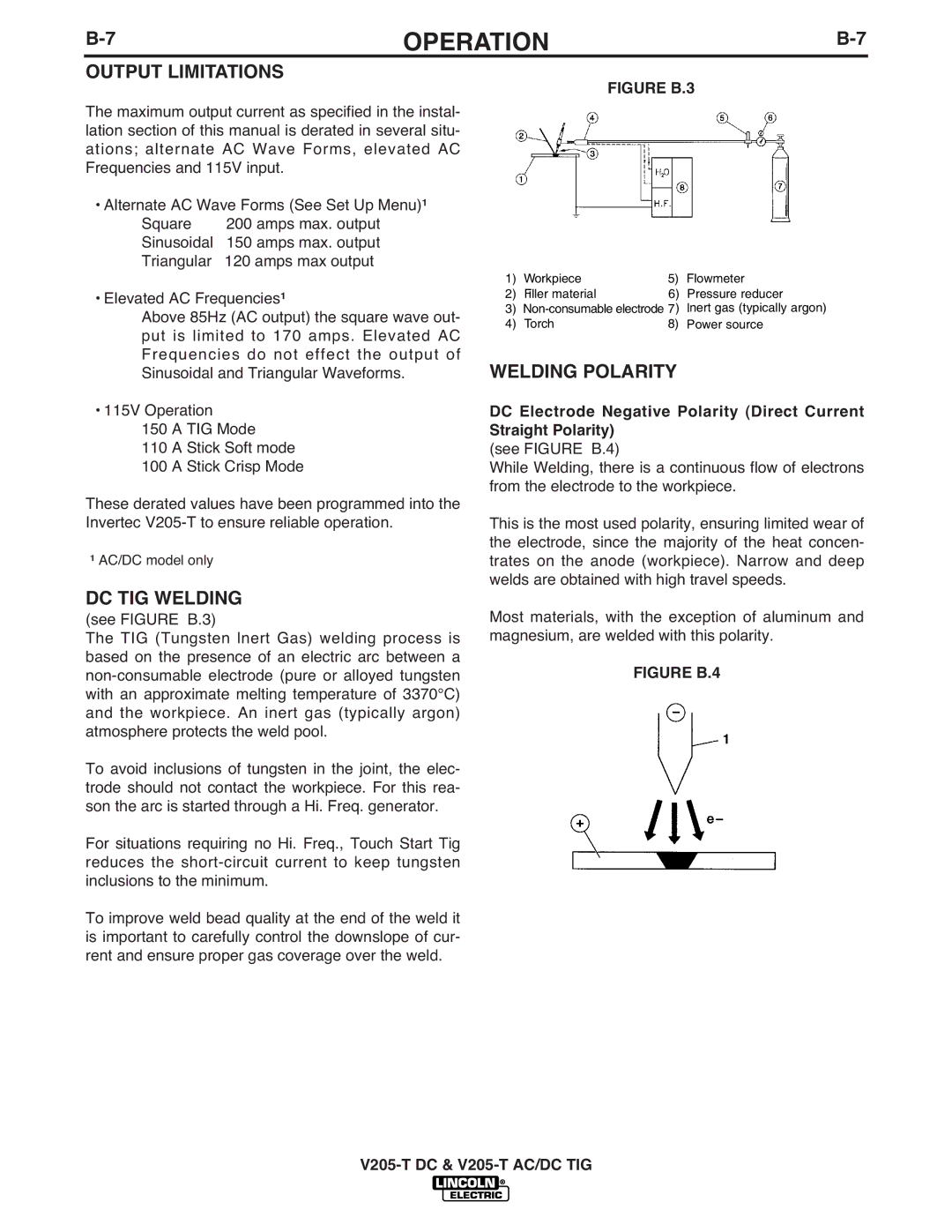

DC TIG WELDING (see FIGURE B.3)

The TIG (Tungsten lnert Gas) welding process is based on the presence of an electric arc between a

To avoid inclusions of tungsten in the joint, the elec- trode should not contact the workpiece. For this rea- son the arc is started through a Hi. Freq. generator.

For situations requiring no Hi. Freq., Touch Start Tig reduces the

To improve weld bead quality at the end of the weld it is important to carefully control the downslope of cur- rent and ensure proper gas coverage over the weld.

FIGURE B.3

1) | Workpiece | 5) | Flowmeter |

2) | Filler material | 6) | Pressure reducer |

3) | lnert gas (typically argon) | ||

4) | Torch | 8) | Power source |

WELDING POLARITY

DC Electrode Negative Polarity (Direct Current Straight Polarity)

(see FIGURE B.4)

While Welding, there is a continuous flow of electrons from the electrode to the workpiece.

This is the most used polarity, ensuring limited wear of the electrode, since the majority of the heat concen- trates on the anode (workpiece). Narrow and deep welds are obtained with high travel speeds.

Most materials, with the exception of aluminum and magnesium, are welded with this polarity.