|

|

|

|

|

| OPERATION |

| |||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

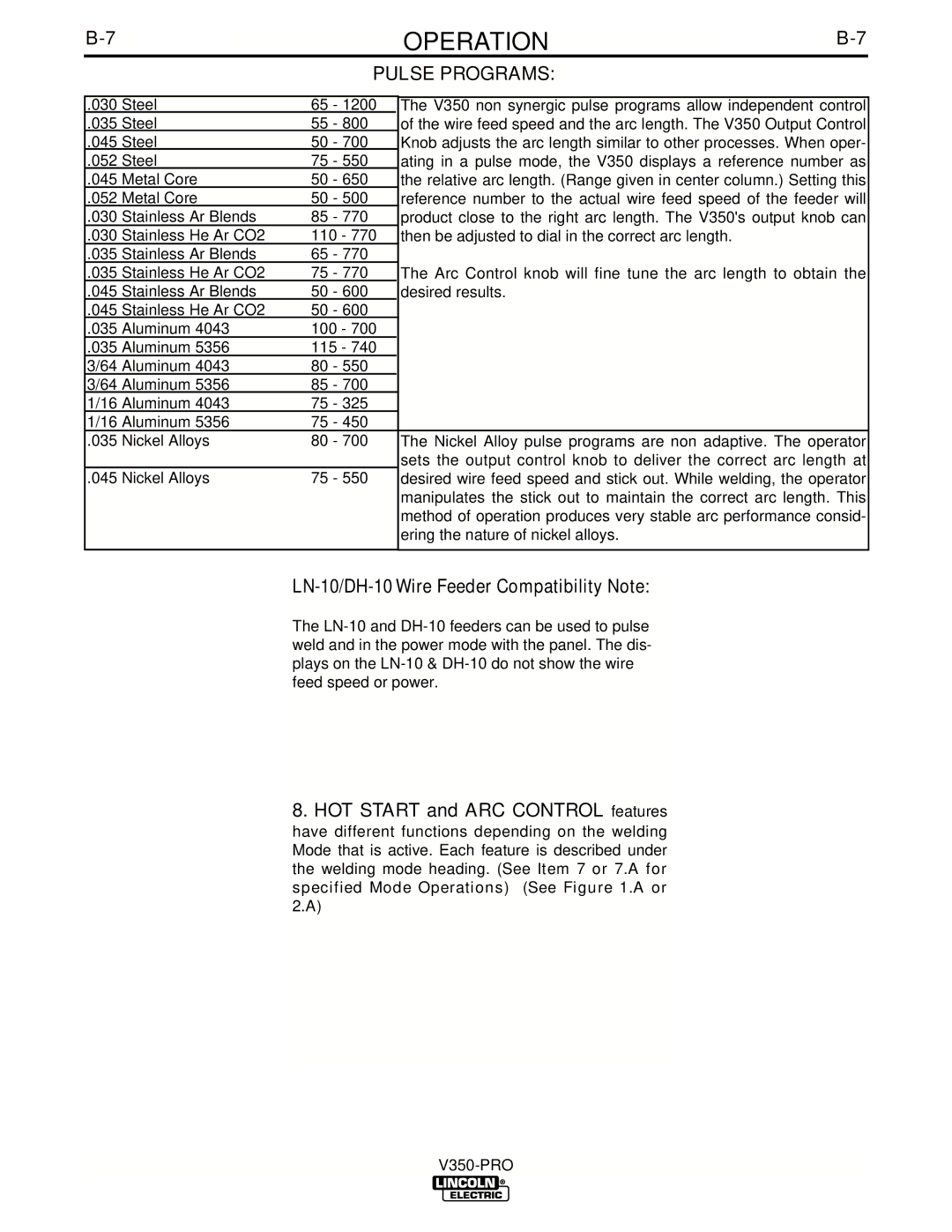

| PULSE PROGRAMS: |

| |||

|

|

|

|

| ||||||

.030 | Steel | 65 | - 1200 | The V350 non synergic pulse programs allow independent control | ||||||

.035 | Steel | 55 | - 800 |

| of the wire feed speed and the arc length. The V350 Output Control | |||||

.045 | Steel | 50 | - 700 |

| Knob adjusts the arc length similar to other processes. When oper- | |||||

.052 | Steel | 75 | - 550 |

| ating in a pulse mode, the V350 displays a reference number as | |||||

.045 | Metal Core | 50 | - 650 |

| the relative arc length. (Range given in center column.) Setting this | |||||

.052 | Metal Core | 50 | - 500 |

| reference number to the actual wire feed speed of the feeder will | |||||

.030 | Stainless Ar Blends | 85 | - 770 |

| product close to the right arc length. The V350's output knob can | |||||

.030 | Stainless He Ar CO2 | 110 - 770 | then be adjusted to dial in the correct arc length. |

| ||||||

.035 | Stainless Ar Blends | 65 | - 770 |

| The Arc Control knob will fine tune the arc length to obtain the | |||||

.035 | Stainless He Ar CO2 | 75 | - 770 |

| ||||||

.045 | Stainless Ar Blends | 50 | - 600 |

| desired results. |

| ||||

.045 | Stainless He Ar CO2 | 50 | - 600 |

|

|

|

|

| ||

.035 | Aluminum 4043 | 100 - 700 |

|

|

|

| ||||

.035 | Aluminum 5356 | 115 - 740 |

|

|

|

| ||||

3/64 Aluminum 4043 | 80 | - 550 |

|

|

|

|

| |||

3/64 Aluminum 5356 | 85 | - 700 |

|

|

|

|

| |||

1/16 Aluminum 4043 | 75 | - 325 |

|

|

|

|

| |||

1/16 Aluminum 5356 | 75 | - 450 |

|

|

|

|

| |||

.035 | Nickel Alloys | 80 | - 700 |

| The Nickel Alloy pulse programs are non adaptive. The operator | |||||

|

|

|

|

|

|

| sets the output control knob to deliver the correct arc length at | |||

.045 | Nickel Alloys | 75 | - 550 |

| desired wire feed speed and stick out. While welding, the operator | |||||

|

|

|

|

|

|

| manipulates the stick out to maintain the correct arc length. This | |||

|

|

|

|

|

|

| method of operation produces very stable arc performance consid- | |||

|

|

|

|

|

|

| ering the nature of nickel alloys. |

| ||

|

|

|

|

|

|

|

|

|

|

|

LN-10/DH-10 Wire Feeder Compatibility Note:

The

8. HOT START and ARC CONTROL features have different functions depending on the welding Mode that is active. Each feature is described under the welding mode heading. (See Item 7 or 7.A for specified Mode Operations) (See Figure 1.A or 2.A)