INSTALLATION | ||

|

|

|

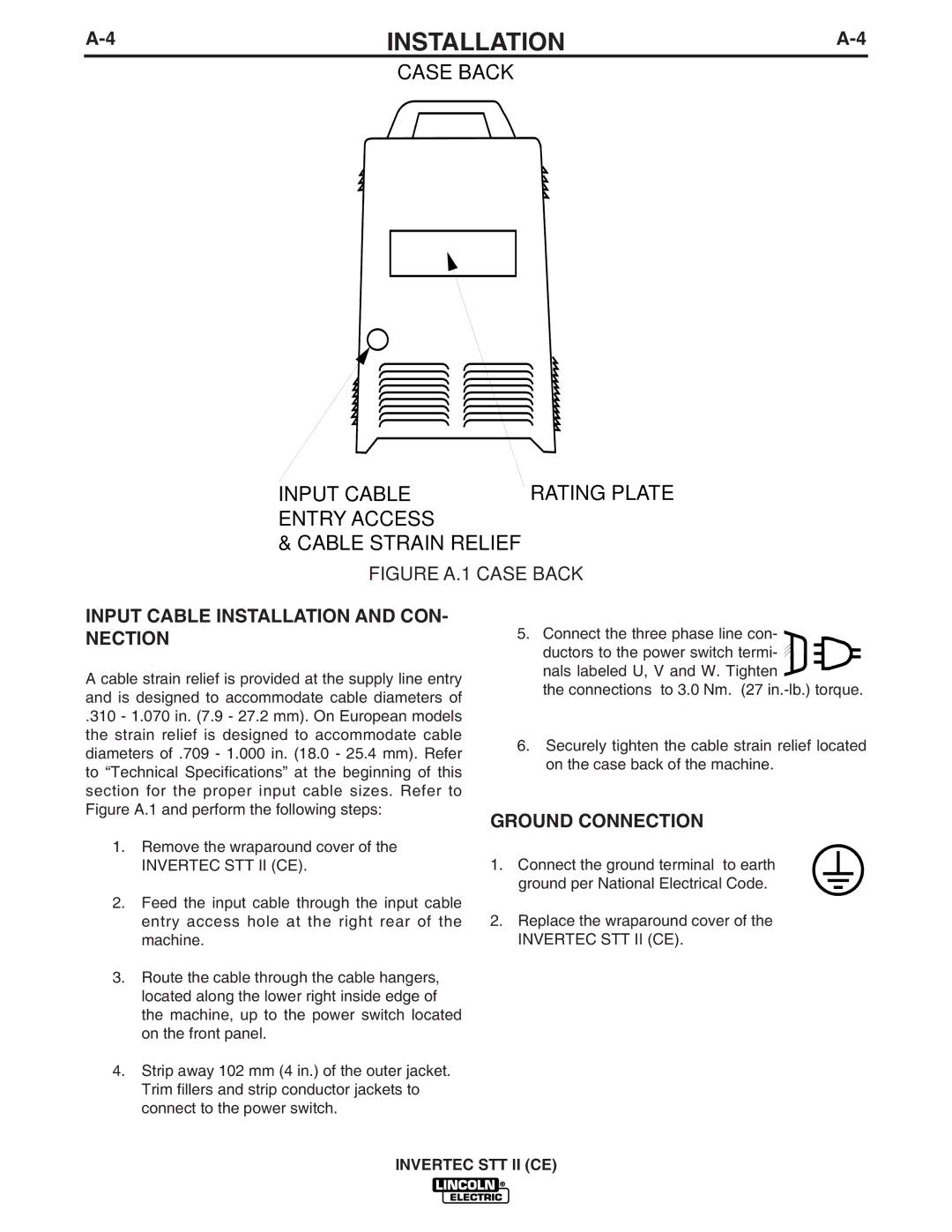

CASE BACK

INPUT CABLE | RATING PLATE |

ENTRY ACCESS |

|

&CABLE STRAIN RELIEF

FIGURE A.1 CASE BACK

INPUT CABLE INSTALLATION AND CON- NECTION

A cable strain relief is provided at the supply line entry and is designed to accommodate cable diameters of

.310 - 1.070 in. (7.9 - 27.2 mm). On European models the strain relief is designed to accommodate cable diameters of .709 - 1.000 in. (18.0 - 25.4 mm). Refer to “Technical Specifications” at the beginning of this section for the proper input cable sizes. Refer to Figure A.1 and perform the following steps:

1.Remove the wraparound cover of the

INVERTEC STT II (CE).

2.Feed the input cable through the input cable entry access hole at the right rear of the machine.

3.Route the cable through the cable hangers, located along the lower right inside edge of the machine, up to the power switch located on the front panel.

4.Strip away 102 mm (4 in.) of the outer jacket. Trim fillers and strip conductor jackets to connect to the power switch.

5.Connect the three phase line con- ductors to the power switch termi- nals labeled U, V and W. Tighten

the connections to 3.0 Nm. (27

6.Securely tighten the cable strain relief located on the case back of the machine.

GROUND CONNECTION

1. Connect the ground terminal to earth ground per National Electrical Code.

2.Replace the wraparound cover of the

INVERTEC STT II (CE).

INVERTEC STT II (CE)