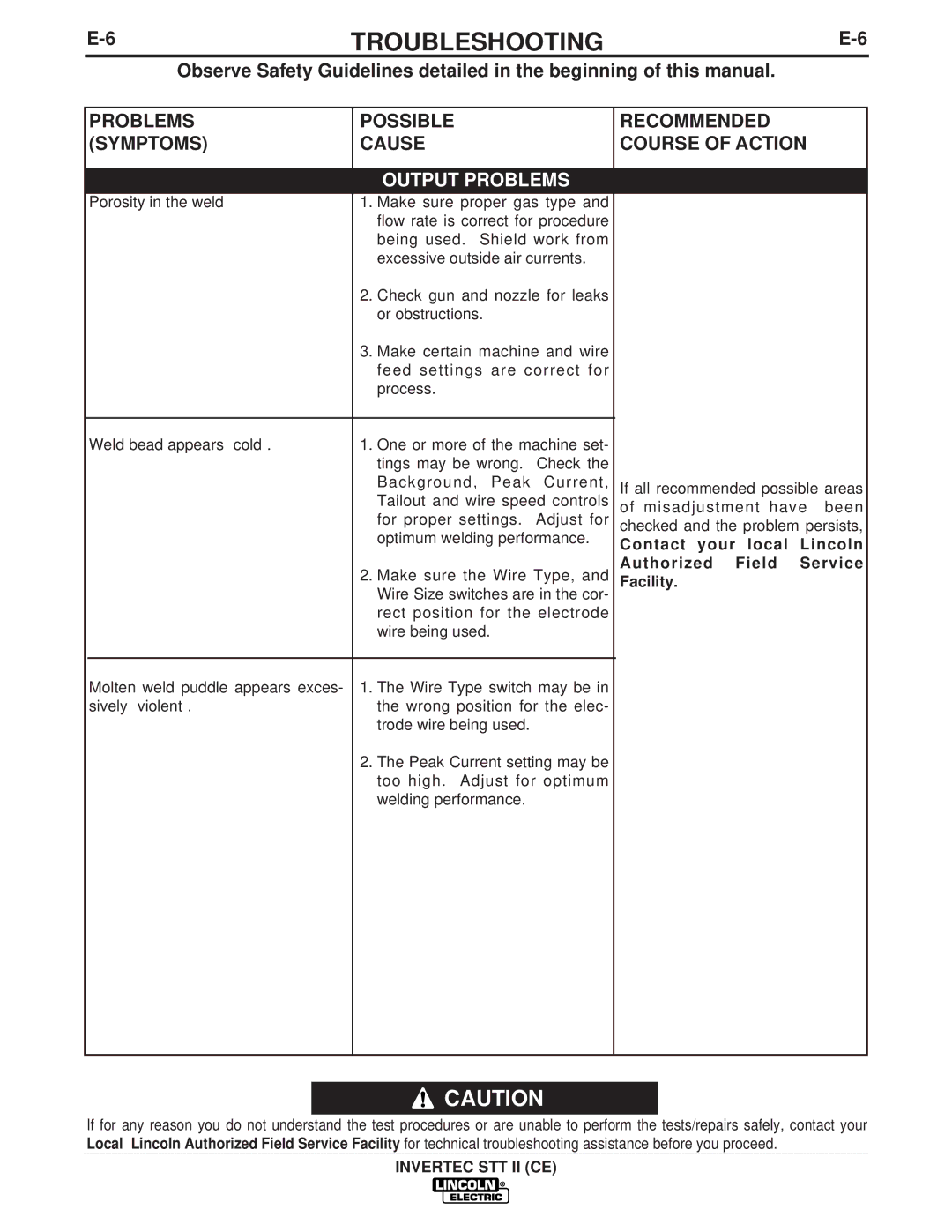

TROUBLESHOOTING | ||

|

|

|

| Observe Safety Guidelines detailed in the beginning of this manual. |

|

PROBLEMS (SYMPTOMS)

POSSIBLE

CAUSE

OUTPUT PROBLEMS

RECOMMENDED COURSE OF ACTION

| Porosity in the weld | 1. | Make sure proper gas type and |

|

|

|

| flow rate is correct for procedure |

|

|

|

| being used. Shield work from |

|

|

|

| excessive outside air currents. |

|

|

| 2. | Check gun and nozzle for leaks |

|

|

|

| or obstructions. |

|

|

| 3. | Make certain machine and wire |

|

|

|

| feed settings are correct for |

|

|

|

| process. |

|

|

|

|

|

|

| Weld bead appears “cold”. | 1. | One or more of the machine set- |

|

|

|

| tings may be wrong. Check the |

|

|

|

| Background, Peak Current, |

|

|

|

| Tailout and wire speed controls |

|

|

|

| for proper settings. Adjust for |

|

|

|

| optimum welding performance. |

|

|

| 2. Make sure the Wire Type, and |

| |

|

|

| Wire Size switches are in the cor- |

|

|

|

| rect position for the electrode |

|

|

|

| wire being used. |

|

|

|

|

|

|

| Molten weld puddle appears exces- | 1. | The Wire Type switch may be in |

|

| sively “violent”. |

| the wrong position for the elec- |

|

|

|

| trode wire being used. |

|

|

| 2. | The Peak Current setting may be |

|

|

|

| too high. Adjust for optimum |

|

|

|

| welding performance. |

|

|

|

|

|

|

If all recommended possible areas of misadjustment have been checked and the problem persists,

Contact your local Lincoln Authorized Field Service Facility.

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

INVERTEC STT II (CE)