OPERATION | ||

|

|

|

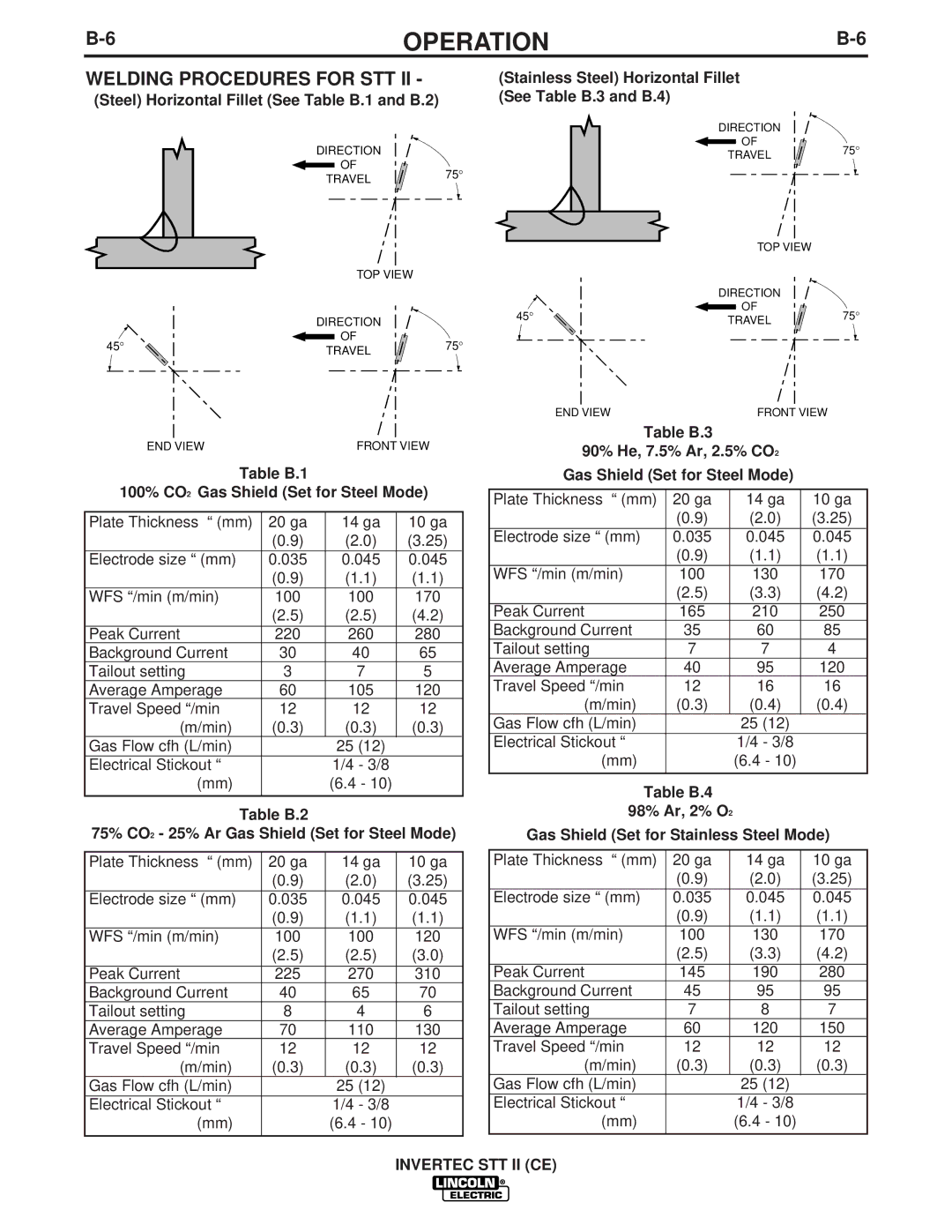

WELDING PROCEDURES FOR STT II -

(Steel) Horizontal Fillet (See Table B.1 and B.2)

DIRECTION |

| |

OF | 75° | |

TRAVEL | ||

|

| TOP VIEW |

| |

| DIRECTION |

| |

45° | OF | 75° | |

TRAVEL | |||

|

|

END VIEW |

| FRONT VIEW | |

Table B.1 |

|

| |

100% CO2 Gas Shield (Set for Steel Mode) | |||

|

|

|

|

Plate Thickness “ (mm) | 20 ga | 14 ga | 10 ga |

| (0.9) | (2.0) | (3.25) |

Electrode size “ (mm) | 0.035 | 0.045 | 0.045 |

| (0.9) | (1.1) | (1.1) |

WFS “/min (m/min) | 100 | 100 | 170 |

| (2.5) | (2.5) | (4.2) |

Peak Current | 220 | 260 | 280 |

Background Current | 30 | 40 | 65 |

Tailout setting | 3 | 7 | 5 |

Average Amperage | 60 | 105 | 120 |

Travel Speed “/min | 12 | 12 | 12 |

(m/min) | (0.3) | (0.3) | (0.3) |

Gas Flow cfh (L/min) |

| 25 (12) |

|

Electrical Stickout “ |

| 1/4 - 3/8 |

|

(mm) |

| (6.4 - 10) |

|

|

|

|

|

Table B.2

75% CO2 - 25% Ar Gas Shield (Set for Steel Mode)

Plate Thickness “ (mm) | 20 ga | 14 ga | 10 ga |

| (0.9) | (2.0) | (3.25) |

Electrode size “ (mm) | 0.035 | 0.045 | 0.045 |

| (0.9) | (1.1) | (1.1) |

WFS “/min (m/min) | 100 | 100 | 120 |

| (2.5) | (2.5) | (3.0) |

|

|

|

|

Peak Current | 225 | 270 | 310 |

Background Current | 40 | 65 | 70 |

Tailout setting | 8 | 4 | 6 |

Average Amperage | 70 | 110 | 130 |

Travel Speed “/min | 12 | 12 | 12 |

(m/min) | (0.3) | (0.3) | (0.3) |

Gas Flow cfh (L/min) |

| 25 (12) |

|

Electrical Stickout “ |

| 1/4 - 3/8 |

|

(mm) |

| (6.4 - 10) |

|

|

|

|

|

(Stainless Steel) Horizontal Fillet

(See Table B.3 and B.4)

DIRECTION |

| |

OF | 75° | |

TRAVEL | ||

|

| TOP VIEW |

| |

| DIRECTION |

| |

45° | OF | 75° | |

TRAVEL | |||

|

|

END VIEW |

| FRONT VIEW | |

Table B.3 |

|

| |

90% He, 7.5% Ar, 2.5% CO2 |

| ||

Gas Shield (Set for Steel Mode) |

| ||

|

|

|

|

Plate Thickness “ (mm) | 20 ga | 14 ga | 10 ga |

| (0.9) | (2.0) | (3.25) |

Electrode size “ (mm) | 0.035 | 0.045 | 0.045 |

| (0.9) | (1.1) | (1.1) |

WFS “/min (m/min) | 100 | 130 | 170 |

| (2.5) | (3.3) | (4.2) |

|

|

|

|

Peak Current | 165 | 210 | 250 |

Background Current | 35 | 60 | 85 |

Tailout setting | 7 | 7 | 4 |

Average Amperage | 40 | 95 | 120 |

Travel Speed “/min | 12 | 16 | 16 |

(m/min) | (0.3) | (0.4) | (0.4) |

Gas Flow cfh (L/min) |

| 25 (12) |

|

Electrical Stickout “ |

| 1/4 - 3/8 |

|

(mm) |

| (6.4 - 10) |

|

|

|

|

|

Table B.4

98% Ar, 2% O2

Gas Shield (Set for Stainless Steel Mode)

Plate Thickness “ (mm) | 20 ga | 14 ga | 10 ga |

| (0.9) | (2.0) | (3.25) |

Electrode size “ (mm) | 0.035 | 0.045 | 0.045 |

| (0.9) | (1.1) | (1.1) |

WFS “/min (m/min) | 100 | 130 | 170 |

| (2.5) | (3.3) | (4.2) |

|

|

|

|

Peak Current | 145 | 190 | 280 |

Background Current | 45 | 95 | 95 |

Tailout setting | 7 | 8 | 7 |

Average Amperage | 60 | 120 | 150 |

Travel Speed “/min | 12 | 12 | 12 |

(m/min) | (0.3) | (0.3) | (0.3) |

Gas Flow cfh (L/min) |

| 25 (12) |

|

Electrical Stickout “ |

| 1/4 - 3/8 |

|

(mm) |

| (6.4 - 10) |

|

|

|

|

|

INVERTEC STT II (CE)