|

| OPERATION |

|

| |||||

|

|

|

|

|

|

|

|

| |

4. ARC CONTROL- The ARC CONTROL dial is active in | 10. WIRE FEEDER VOLTMETER SWITCH: | ||||||||

the | Matches the polarity of the wire feeder voltmeter to | ||||||||

and has different functions in these modes. This control is | the polarity of the electrode. |

| |||||||

not active in the TIG mode. |

|

| 11. VRD (Voltage Reduction Device) INDICA- | ||||||

|

|

|

|

| |||||

TOR LIGHTS- On the front panel of the Vantage | |||||||||

sets the short circuit current | 300 are two indicator lights. A red light when lit indi- | ||||||||

to adjust for a soft or crisp arc. Increasing the dial from | |||||||||

cates OCV(Open Circuit Voltage) is equal to or | |||||||||

(soft) to +10 (crisp) increases the short circuit current and | |||||||||

greater than 30V and a green light when lit indicates | |||||||||

prevents sticking of the electrode to the plate while welding. | |||||||||

OCV(Open Circuit Voltage) is less than 30V. | |||||||||

This can also increase spatter. It is recommended that the | |||||||||

|

|

|

| ||||||

ARC CONTROL be set to the minimum number without | The VRD “On/Off” switch inside the control panel | ||||||||

electrode sticking. Start with a setting at 0. |

|

| |||||||

|

| must be “On” for the VRD function to be active and | |||||||

|

|

|

|

| |||||

DOWNHILL PIPE mode: In this mode, the ARC CONTROL | the lights to be enabled. When the machine is first | ||||||||

started with VRD enabled, both lights will illuminate | |||||||||

dial sets the short circuit current | |||||||||

for 5 seconds. |

| ||||||||

welding to adjust for a soft or a more forceful digging arc |

| ||||||||

|

|

|

| ||||||

(crisp). Increasing the number from | These lights monitor the OCV(Open Circuit Voltage) | ||||||||

increases the short circuit current which results in a more | |||||||||

and weld voltage at all times. In the | |||||||||

forceful digging arc. Typically a forceful digging arc is pre- | |||||||||

when not welding the green light will illuminate indi- | |||||||||

ferred for root and hot passes. A softer arc is preferred for fill | |||||||||

cating that the VRD has reduced the OCV to less | |||||||||

and cap passes where weld puddle control and deposition | |||||||||

than 30V. During welding the red light will illuminate | |||||||||

("stacking" of iron) are key to fast travel speeds. It is recom- | |||||||||

whenever the arc voltage is equal to or greater than | |||||||||

mended that the ARC CONTROL be set initially at 0. | |||||||||

30V. This means that the red and green light may | |||||||||

|

|

|

|

| |||||

alternate depending on the weld voltage. This is nor- | |||||||||

mal operation. |

| ||||||||

clock wise from |

| ||||||||

|

|

|

| ||||||

from soft and | If the red light remains illuminated when not welding | ||||||||

inductance/pinch control. The proper setting depends on the | |||||||||

in the | |||||||||

procedure and operator preference. Start with a setting of 0. | |||||||||

properly. Please refer to your local field service shop | |||||||||

|

|

|

|

| |||||

5. WELD OUTPUT TERMINALS WITH | FLANGE | for service. |

|

| |||||

|

|

|

| ||||||

NUT- Provides a connection point for the electrode and | If the VRD is turned “On” and the lights don’t come | ||||||||

work cables. |

|

|

| ||||||

|

|

| “On”, refer to the trouble shooting section. |

| |||||

|

|

|

|

|

| ||||

6. GROUND STUD- | Provides a connection point for |

|

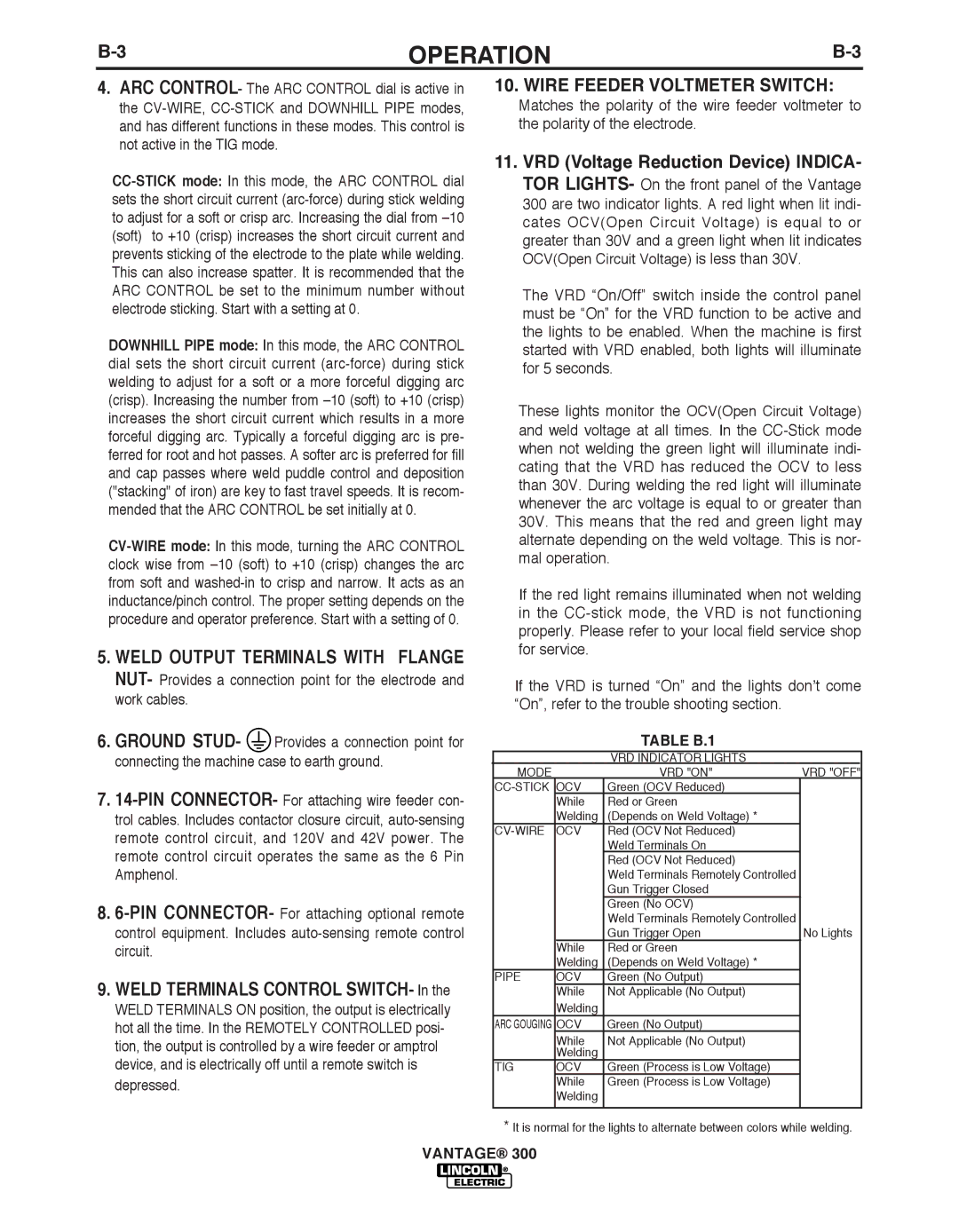

| TAbLE b.1 |

| ||||

connecting the machine case to earth ground. |

|

|

|

| VRD INDICATOR LIGHTS |

| |||

|

| MODE |

| VRD "ON" | VRD "OFF" | ||||

|

|

|

|

|

| ||||

7. | OCV | Green (OCV Reduced) |

| ||||||

| While | Red or Green |

| ||||||

trol cables. Includes contactor closure circuit, |

| Welding | (Depends on Weld Voltage) * |

| |||||

OCV | Red (OCV Not Reduced) |

| |||||||

remote control circuit, and 120V and 42V power. The |

| ||||||||

|

| Weld Terminals On |

| ||||||

remote control circuit operates the same as the 6 Pin |

|

|

| ||||||

|

| Red (OCV Not Reduced) |

| ||||||

Amphenol. |

|

|

|

|

| Weld Terminals Remotely Controlled |

| ||

|

|

|

|

|

|

| Gun Trigger Closed |

| |

8. |

|

| Green (No OCV) |

| |||||

|

| Weld Terminals Remotely Controlled |

| ||||||

control equipment. Includes |

|

| Gun Trigger Open | No Lights | |||||

circuit. |

|

|

|

| While | Red or Green |

| ||

|

|

|

|

|

| Welding | (Depends on Weld Voltage) * |

| |

9. WELD TERMINALS CONTROL SWITCH- In the | PIPE | OCV | Green (No Output) |

| |||||

| While | Not Applicable (No Output) |

| ||||||

WELD TERMINALS ON position, the output is electrically |

| Welding |

|

| |||||

hot all the time. In the REMOTELY CONTROLLED posi- | ARC GOUGING | OCV | Green (No Output) |

| |||||

| While | Not Applicable (No Output) |

| ||||||

tion, the output is controlled by a wire feeder or amptrol |

|

| |||||||

| Welding |

|

| ||||||

device, and is electrically off until a remote switch is |

|

|

| ||||||

TIG | OCV | Green (Process is Low Voltage) |

| ||||||

depressed. |

|

|

|

| While | Green (Process is Low Voltage) |

| ||

|

|

|

|

|

| Welding |

|

| |

|

|

|

|

|

|

|

|

| |

|

|

|

|

| * It is normal for the lights to alternate between colors while welding. | ||||

|

|

| VANTAGE® 300 |

|

|

| |||