INSTALLATION | ||

|

|

|

WELDING OUTPUT CAbLES

With the engine off connect the electrode and work cables to the output studs. The welding process dic- tates the polarity of the electrode cable. These con- nections should be checked periodically and tightened with a 3/4" wrench.

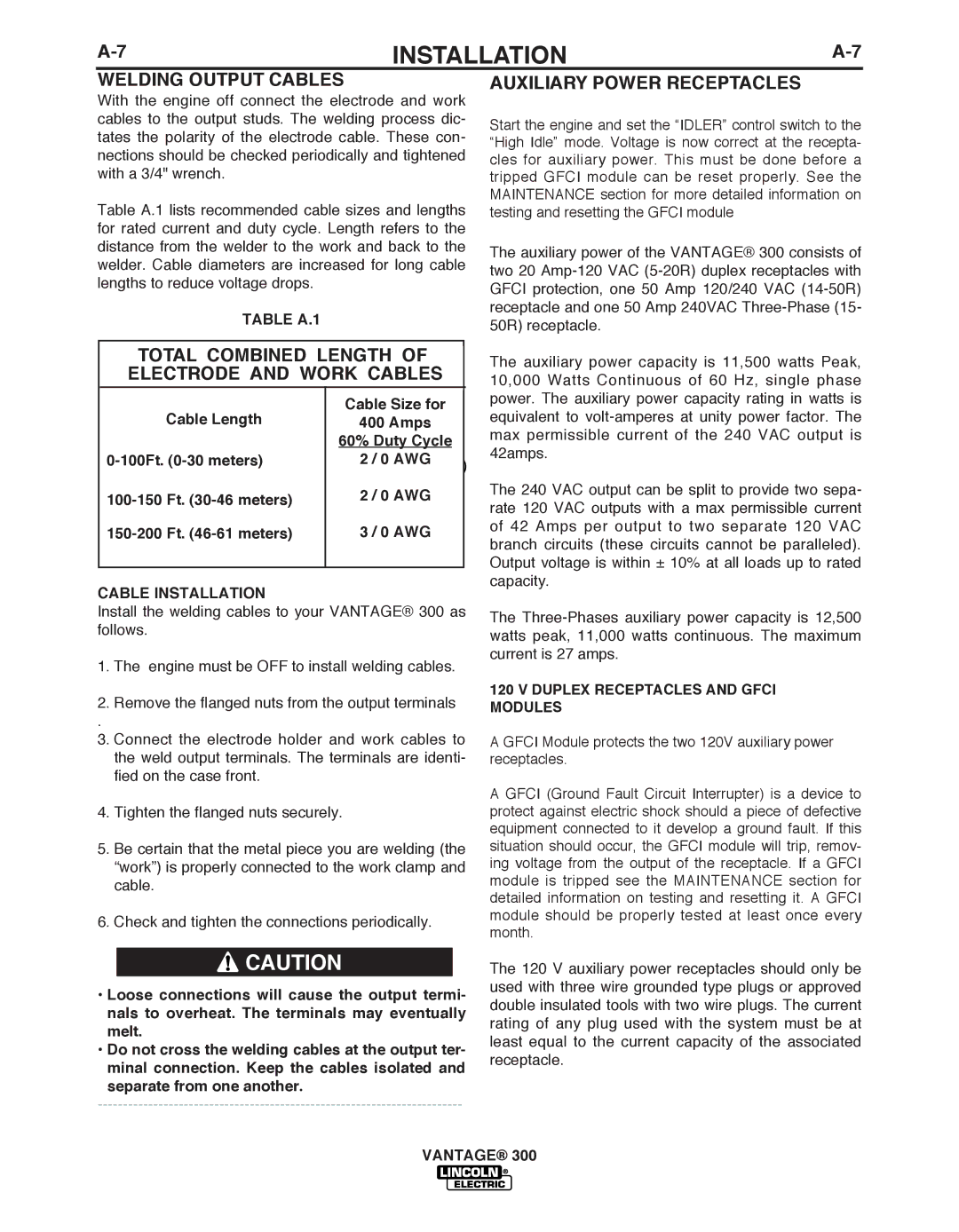

Table A.1 lists recommended cable sizes and lengths for rated current and duty cycle. Length refers to the distance from the welder to the work and back to the welder. Cable diameters are increased for long cable lengths to reduce voltage drops.

TAbLE A.1

TOTAL COMbINED LENGTH OF ELECTRODE AND WORK CAbLES

AUXILIARY POWER RECEPTACLES

Start the engine and set the “IDLER” control switch to the “High Idle” mode. Voltage is now correct at the recepta- cles for auxiliary power. This must be done before a tripped GFCI module can be reset properly. See the MAINTENANCE section for more detailed information on testing and resetting the GFCI module

The auxiliary power of the VANTAGE® 300 consists of two 20

The auxiliary power capacity is 11,500 watts Peak, 10,000 Watts Continuous of 60 Hz, single phase

Cable Length

Cable Size for

400Amps

60% Duty Cycle

2 / 0 AWG ![]()

2 / 0 AWG

3 / 0 AWG

power. The auxiliary power capacity rating in watts is equivalent to

The 240 VAC output can be split to provide two sepa- rate 120 VAC outputs with a max permissible current of 42 Amps per output to two separate 120 VAC branch circuits (these circuits cannot be paralleled). Output voltage is within ± 10% at all loads up to rated capacity.

CAbLE INSTALLATION

Install the welding cables to your VANTAGE® 300 as follows.

1.The engine must be OFF to install welding cables.

2.Remove the flanged nuts from the output terminals

.

3.Connect the electrode holder and work cables to the weld output terminals. The terminals are identi- fied on the case front.

4.Tighten the flanged nuts securely.

5.Be certain that the metal piece you are welding (the “work”) is properly connected to the work clamp and cable.

6.Check and tighten the connections periodically.

![]() CAUTION

CAUTION

•Loose connections will cause the output termi- nals to overheat. The terminals may eventually melt.

•Do not cross the welding cables at the output ter- minal connection. Keep the cables isolated and separate from one another.

The

120 V DUPLEX RECEPTACLES AND GFCI MODULES

A GFCI Module protects the two 120V auxiliary power receptacles.

A GFCI (Ground Fault Circuit Interrupter) is a device to protect against electric shock should a piece of defective equipment connected to it develop a ground fault. If this situation should occur, the GFCI module will trip, remov- ing voltage from the output of the receptacle. If a GFCI module is tripped see the MAINTENANCE section for detailed information on testing and resetting it. A GFCI module should be properly tested at least once every month.

The 120 V auxiliary power receptacles should only be used with three wire grounded type plugs or approved double insulated tools with two wire plugs. The current rating of any plug used with the system must be at least equal to the current capacity of the associated receptacle.