|

| INSTALLATION |

| ||

|

|

|

|

|

|

SELECT SUITABLE LOCATION

The SP

STACKING

SP

TILTING

Each machine must be placed on a secure, level sur- face, either directly or on the recommended cart. The machine may topple over if this procedure is not fol- lowed.

LIMITATIONS

The SP

MIG welding and flux cored arc welding are the only processes supported by the SP

The handle can not be used for transport by crane.

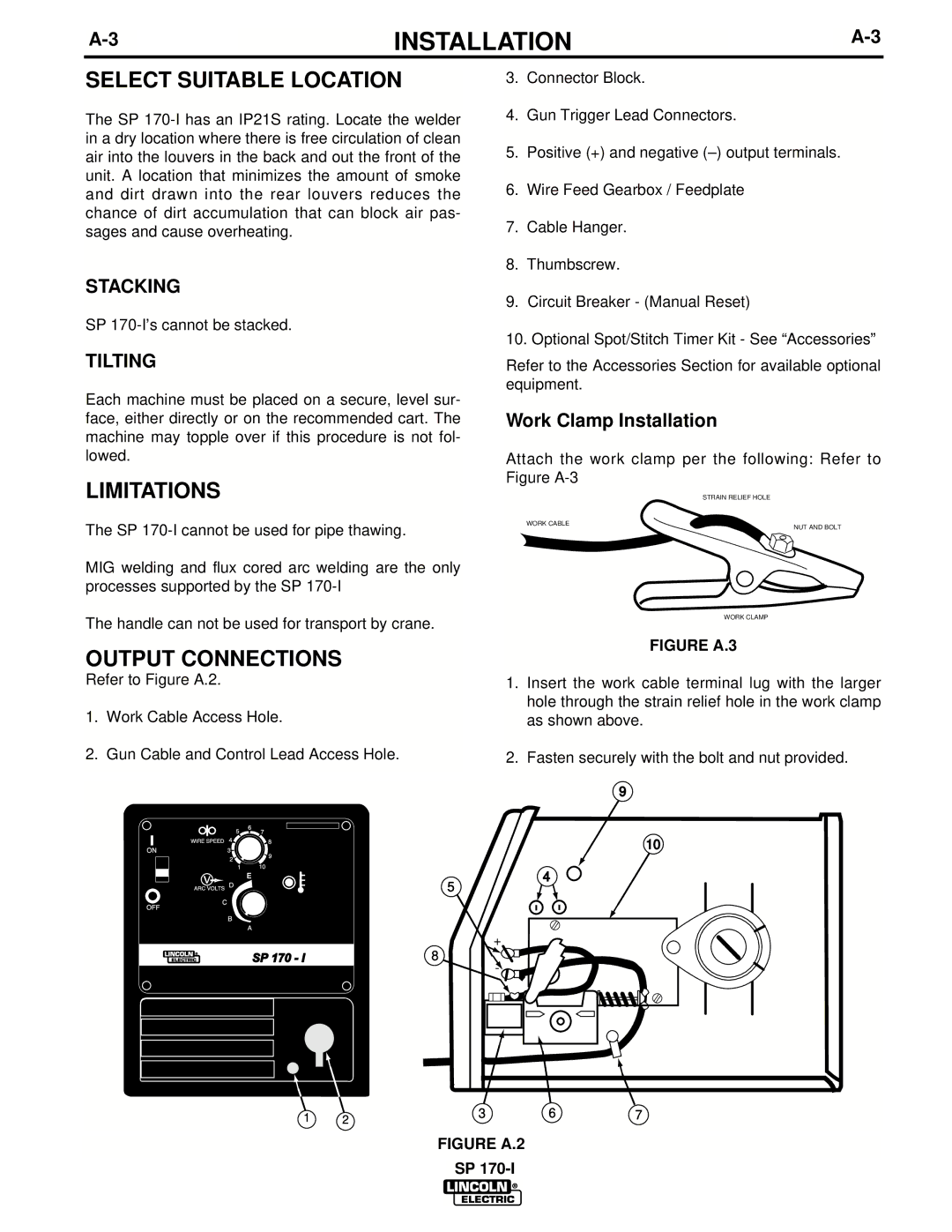

OUTPUT CONNECTIONS

Refer to Figure A.2.

1.Work Cable Access Hole.

2.Gun Cable and Control Lead Access Hole.

E

5

SP 170 - I | 8 |

3.Connector Block.

4.Gun Trigger Lead Connectors.

5.Positive (+) and negative

6.Wire Feed Gearbox / Feedplate

7.Cable Hanger.

8.Thumbscrew.

9.Circuit Breaker - (Manual Reset)

10.Optional Spot/Stitch Timer Kit - See “Accessories”

Refer to the Accessories Section for available optional equipment.

Work Clamp Installation

Attach the work clamp per the following: Refer to Figure

STRAIN RELIEF HOLE

WORK CABLE

NUT AND BOLT

WORK CLAMP

FIGURE A.3

1.Insert the work cable terminal lug with the larger hole through the strain relief hole in the work clamp as shown above.

2.Fasten securely with the bolt and nut provided.

9

10

4

+

-

1 | 2 | 3 | 6 | 7 |

FIGURE A.2

SP