MODEL

BATTERY MAINTENANCE

The

If power is to be removed for one week or more, disconnect the negative wire from the batteries as this will prevent deep discharging.

Fully charge before use after storage or upon initial installation.

BRUSH REPLACEMENT

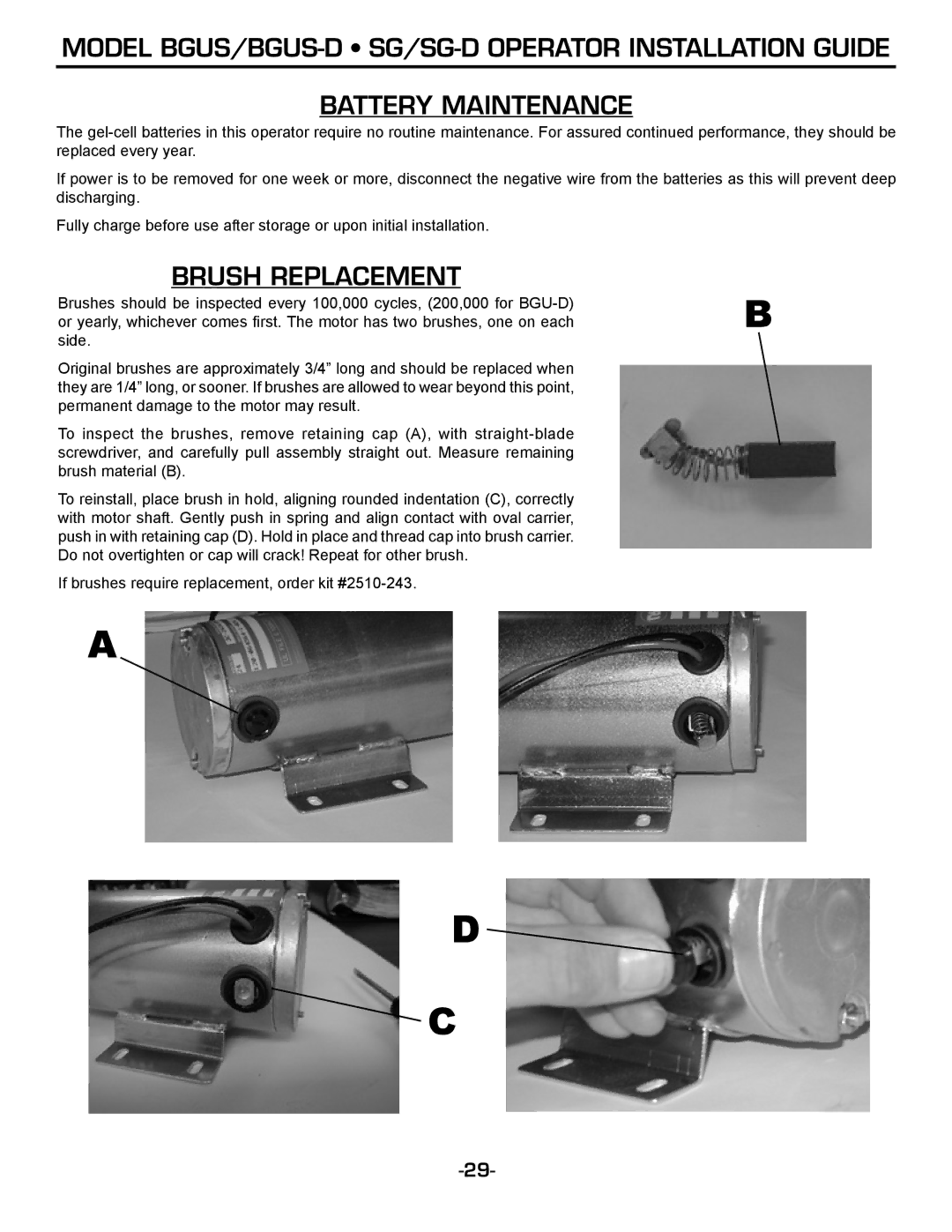

Brushes should be inspected every 100,000 cycles, (200,000 for

Original brushes are approximately 3/4” long and should be replaced when they are 1/4” long, or sooner. If brushes are allowed to wear beyond this point, permanent damage to the motor may result.

To inspect the brushes, remove retaining cap (A), with

To reinstall, place brush in hold, aligning rounded indentation (C), correctly with motor shaft. Gently push in spring and align contact with oval carrier, push in with retaining cap (D). Hold in place and thread cap into brush carrier. Do not overtighten or cap will crack! Repeat for other brush.

If brushes require replacement, order kit

B

A

D ![]()

![]() C

C