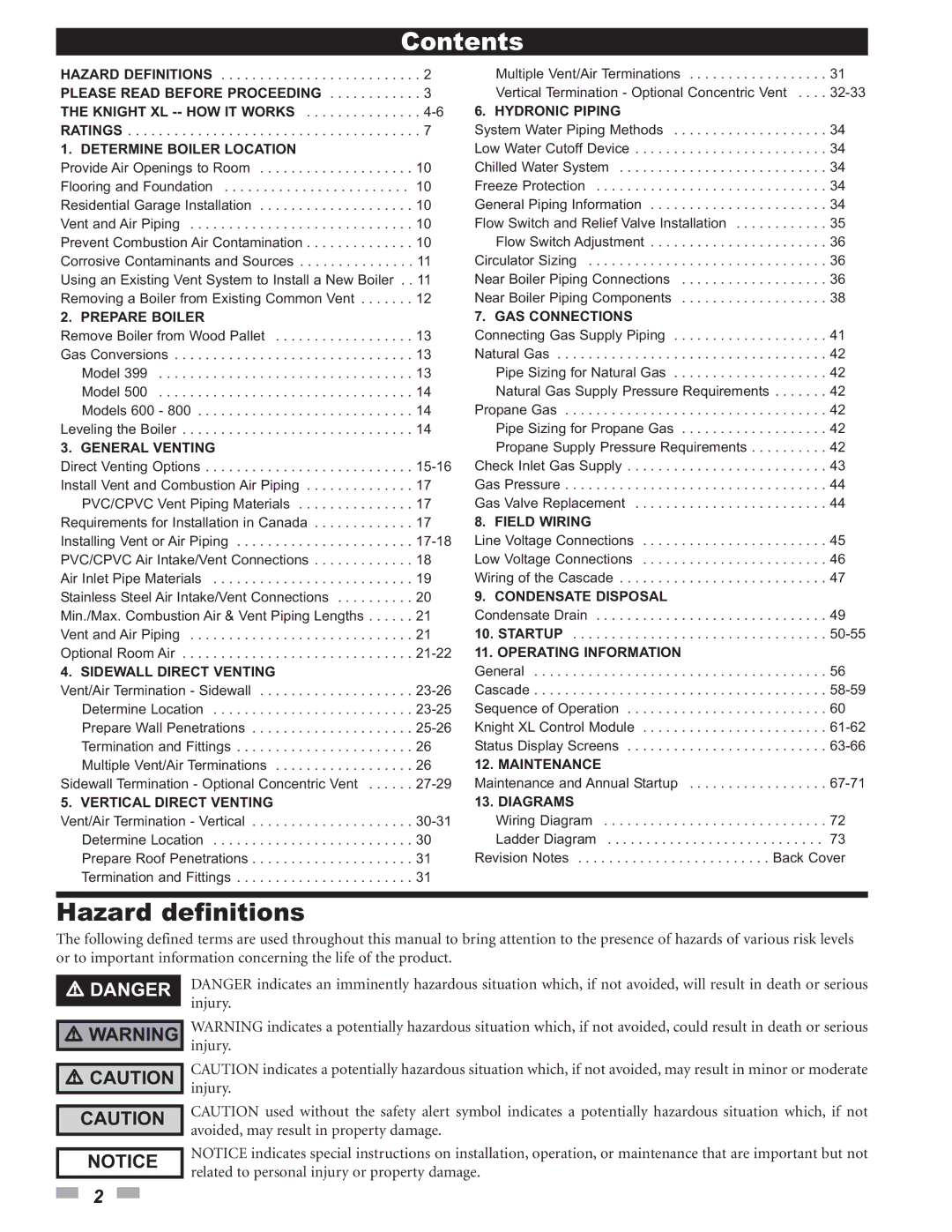

HAZARD DEFINITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 2 PLEASE READ BEFORE PROCEEDING . . . . . . . . . . . . 3 THE KNIGHT XL -- HOW IT WORKS . . . . . . . . . . . . . . . 4-6 RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1. DETERMINE BOILER LOCATION

Provide Air Openings to Room . . . . . . . . . . . . . . . . . . . . 10 Flooring and Foundation . . . . . . . . . . . . . . . . . . . . . . . . 10 Residential Garage Installation . . . . . . . . . . . . . . . . . . . . 10 Vent and Air Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Prevent Combustion Air Contamination . . . . . . . . . . . . . . 10 Corrosive Contaminants and Sources . . . . . . . . . . . . . . . 11 Using an Existing Vent System to Install a New Boiler . . 11 Removing a Boiler from Existing Common Vent . . . . . . . 12

2. PREPARE BOILER

Remove Boiler from Wood Pallet . . . . . . . . . . . . . . . . . . 13 Gas Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Model 399 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Model 500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Models 600 - 800 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Leveling the Boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3. GENERAL VENTING

Direct Venting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16 Install Vent and Combustion Air Piping . . . . . . . . . . . . . . 17

PVC/CPVC Vent Piping Materials . . . . . . . . . . . . . . . 17 Requirements for Installation in Canada . . . . . . . . . . . . . 17 Installing Vent or Air Piping . . . . . . . . . . . . . . . . . . . . . . . 17-18 PVC/CPVC Air Intake/Vent Connections . . . . . . . . . . . . . 18 Air Inlet Pipe Materials . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Stainless Steel Air Intake/Vent Connections . . . . . . . . . . 20 Min./Max. Combustion Air & Vent Piping Lengths . . . . . . 21 Vent and Air Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Optional Room Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

4. SIDEWALL DIRECT VENTING

Vent/Air Termination - Sidewall . . . . . . . . . . . . . . . . . . . . 23-26

Determine Location . . . . . . . . . . . . . . . . . . . . . . . . . . 23-25

Prepare Wall Penetrations . . . . . . . . . . . . . . . . . . . . . 25-26

Termination and Fittings . . . . . . . . . . . . . . . . . . . . . . . 26

Multiple Vent/Air Terminations . . . . . . . . . . . . . . . . . . 26

Sidewall Termination - Optional Concentric Vent . . . . . . 27-29

5. VERTICAL DIRECT VENTING

Vent/Air Termination - Vertical . . . . . . . . . . . . . . . . . . . . . 30-31

Determine Location . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Prepare Roof Penetrations . . . . . . . . . . . . . . . . . . . . . 31

Termination and Fittings . . . . . . . . . . . . . . . . . . . . . . . 31

Multiple Vent/Air Terminations . . . . . . . . . . . . . . . . . . 31 Vertical Termination - Optional Concentric Vent . . . . 32-33

6. HYDRONIC PIPING

System Water Piping Methods . . . . . . . . . . . . . . . . . . . . 34

Low Water Cutoff Device . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chilled Water System . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

General Piping Information . . . . . . . . . . . . . . . . . . . . . . . 34

Flow Switch and Relief Valve Installation . . . . . . . . . . . . 35

Flow Switch Adjustment . . . . . . . . . . . . . . . . . . . . . . . 36

Circulator Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Near Boiler Piping Connections . . . . . . . . . . . . . . . . . . . 36

Near Boiler Piping Components . . . . . . . . . . . . . . . . . . . 38

7. GAS CONNECTIONS

Connecting Gas Supply Piping . . . . . . . . . . . . . . . . . . . . 41

Natural Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pipe Sizing for Natural Gas . . . . . . . . . . . . . . . . . . . . 42

Natural Gas Supply Pressure Requirements . . . . . . . 42

Propane Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pipe Sizing for Propane Gas . . . . . . . . . . . . . . . . . . . 42

Propane Supply Pressure Requirements . . . . . . . . . . 42

Check Inlet Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Gas Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Gas Valve Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 44

8. FIELD WIRING

Line Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . 45

Low Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . 46

Wiring of the Cascade . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9. CONDENSATE DISPOSAL | |

Condensate Drain | 49 |

10. STARTUP | 50-55 |

11. OPERATING INFORMATION | |

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Cascade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58-59

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Knight XL Control Module . . . . . . . . . . . . . . . . . . . . . . . . 61-62

Status Display Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 63-66

12. MAINTENANCE | |

Maintenance and Annual Startup | 67-71 |

13. DIAGRAMS | |

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Revision Notes . . . . . . . . . . . . . . . . . . . . . . . . . Back Cover