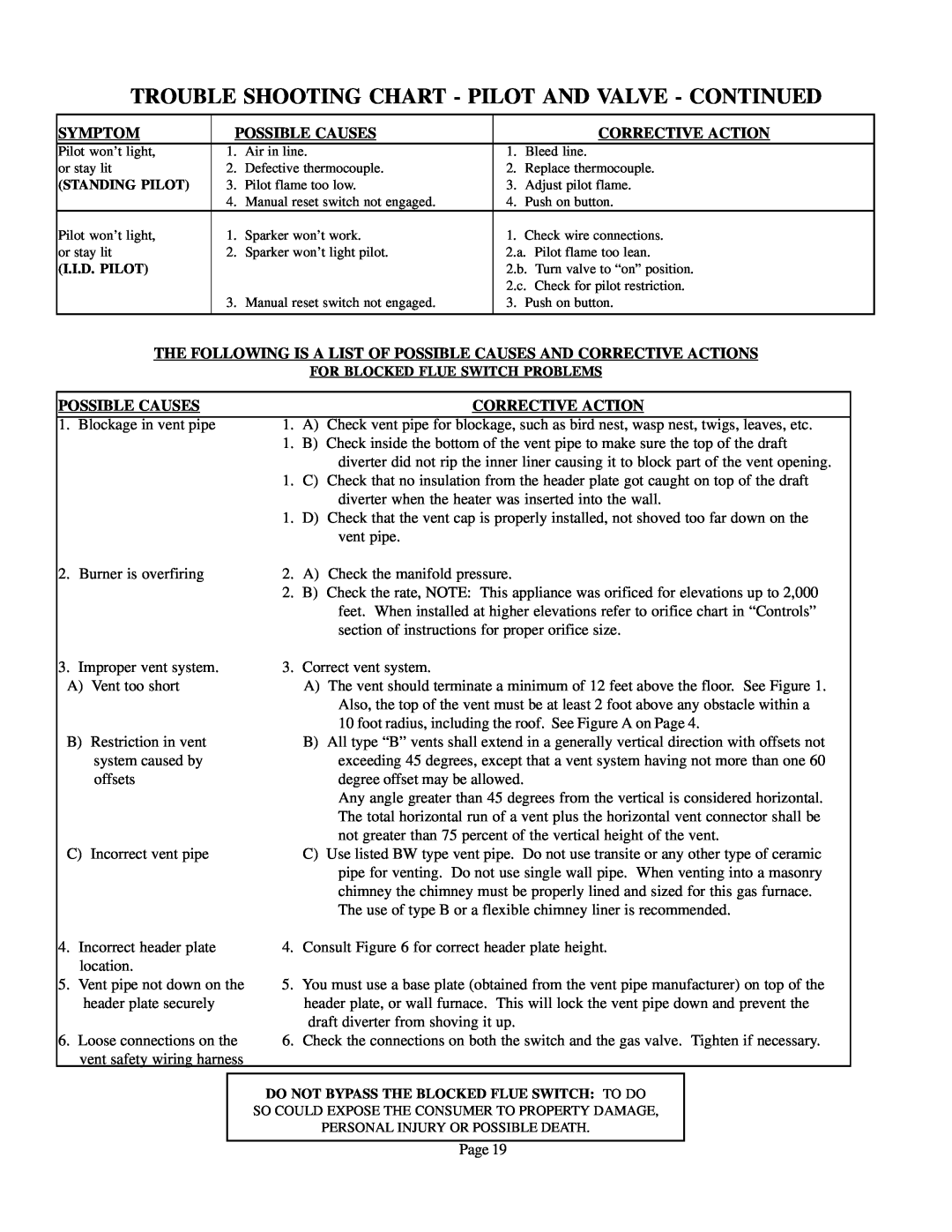

TROUBLE SHOOTING CHART - PILOT AND VALVE - CONTINUED

SYMPTOM | POSSIBLE CAUSES |

| CORRECTIVE ACTION | ||

Pilot won’t light, | 1. | Air in line. | 1. | Bleed line. |

|

or stay lit | 2. | Defective thermocouple. | 2. | Replace thermocouple. | |

(STANDING PILOT) | 3. | Pilot flame too low. | 3. | Adjust pilot flame. | |

| 4. | Manual reset switch not engaged. | 4. | Push on button. | |

Pilot won’t light, | 1. | Sparker won’t work. | 1. | Check wire connections. | |

or stay lit | 2. | Sparker won’t light pilot. | 2.a. Pilot flame too lean. | ||

(I.I.D. PILOT) |

|

| 2.b. Turn valve to “on” position. | ||

|

|

| 2.c. Check for pilot restriction. | ||

| 3. | Manual reset switch not engaged. | 3. | Push on button. | |

|

|

|

|

|

|

THE FOLLOWING IS A LIST OF POSSIBLE CAUSES AND CORRECTIVE ACTIONS

FOR BLOCKED FLUE SWITCH PROBLEMS

POSSIBLE CAUSES |

|

| CORRECTIVE ACTION | ||||

|

|

|

|

| |||

1. | Blockage in vent pipe | 1. | A) | Check vent pipe for blockage, such as bird nest, wasp nest, twigs, leaves, etc. | |||

|

|

|

| 1. | B) | Check inside the bottom of the vent pipe to make sure the top of the draft | |

|

|

|

|

|

| diverter did not rip the inner liner causing it to block part of the vent opening. | |

|

|

|

| 1. | C) | Check that no insulation from the header plate got caught on top of the draft | |

|

|

|

|

|

| diverter when the heater was inserted into the wall. | |

|

|

|

| 1. | D) | Check that the vent cap is properly installed, not shoved too far down on the | |

|

|

|

|

|

| vent pipe. | |

2. | Burner is overfiring | 2. | A) | Check the manifold pressure. | |||

|

|

|

| 2. | B) | Check the rate, NOTE: This appliance was orificed for elevations up to 2,000 | |

|

|

|

|

|

| feet. When installed at higher elevations refer to orifice chart in “Controls” | |

|

|

|

|

|

| section of instructions for proper orifice size. | |

3. | Improper vent system. | 3. | Correct vent system. | ||||

A) | Vent too short |

| A) | The vent should terminate a minimum of 12 feet above the floor. See Figure 1. | |||

|

|

|

|

|

| Also, the top of the vent must be at least 2 foot above any obstacle within a | |

|

|

|

|

|

| 10 foot radius, including the roof. See Figure A on Page 4. | |

B) | Restriction in vent |

| B) | All type “B” vents shall extend in a generally vertical direction with offsets not | |||

|

| system caused by |

|

| exceeding 45 degrees, except that a vent system having not more than one 60 | ||

|

| offsets |

|

| degree offset may be allowed. | ||

|

|

|

|

|

| Any angle greater than 45 degrees from the vertical is considered horizontal. | |

|

|

|

|

|

| The total horizontal run of a vent plus the horizontal vent connector shall be | |

|

|

|

|

|

| not greater than 75 percent of the vertical height of the vent. | |

C) | Incorrect vent pipe |

| C) | Use listed BW type vent pipe. Do not use transite or any other type of ceramic | |||

|

|

|

|

|

| pipe for venting. Do not use single wall pipe. When venting into a masonry | |

|

|

|

|

|

| chimney the chimney must be properly lined and sized for this gas furnace. | |

|

|

|

|

|

| The use of type B or a flexible chimney liner is recommended. | |

4. | Incorrect header plate | 4. | Consult Figure 6 for correct header plate height. | ||||

| location. |

|

|

|

| ||

5. | Vent pipe not down on the | 5. | You must use a base plate (obtained from the vent pipe manufacturer) on top of the | ||||

|

| header plate securely |

| header plate, or wall furnace. This will lock the vent pipe down and prevent the | |||

|

|

|

|

| draft diverter from shoving it up. | ||

6. | Loose connections on the | 6. | Check the connections on both the switch and the gas valve. Tighten if necessary. | ||||

| vent safety wiring harness |

|

|

|

| ||

|

|

|

|

|

| ||

|

|

|

| DO NOT BYPASS THE BLOCKED FLUE SWITCH: TO DO |

| ||

|

|

|

| SO COULD EXPOSE THE CONSUMER TO PROPERTY DAMAGE, |

| ||

|

|

|

|

|

| PERSONAL INJURY OR POSSIBLE DEATH. |

|

|

|

|

|

|

|

|

|

Page 19