Installation of |

|

for | Ceiling plate spacers to center |

first floor of | |

buildings. | nail securely at both ends. |

Plate cut away for full width of stud space to provide ventilation.

Installation of

Firestop spacers supplied by manufacturer of

Plate cut away

to provide passage of

Sheet metal screw base plate to header

Studs on

16 inch centers

Use manufacturer’s method of fastening pipe to base plate.

Header plate of vented wall furnace (also acts as firestop)

FIGURE B

CONTROLS

All controls are

Nail firestop spacer securely

FIGURE C

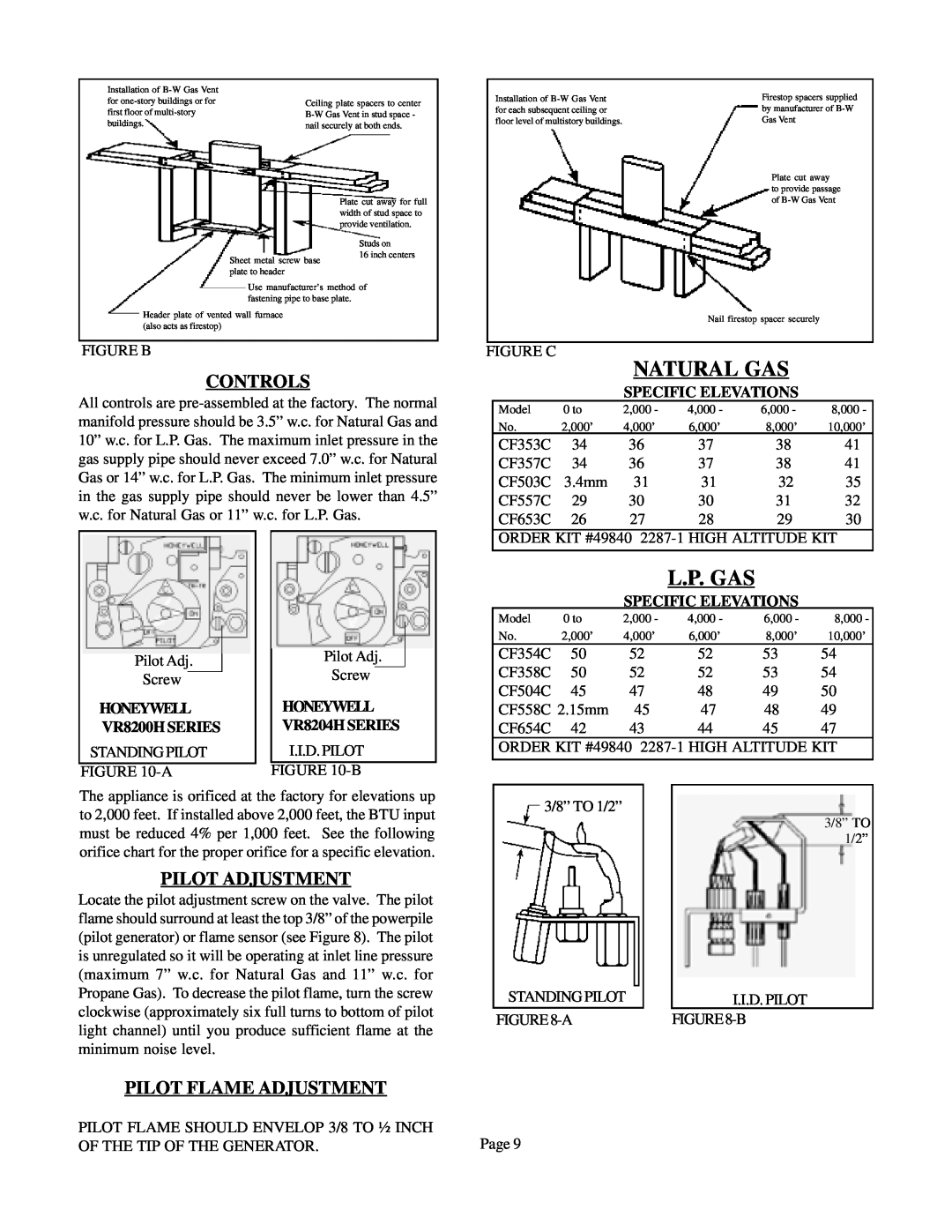

NATURAL GAS

SPECIFIC ELEVATIONS

Model | 0 to | 2,000 - | 4,000 - | 6,000 - | 8,000 - |

No. | 2,000’ | 4,000’ | 6,000’ | 8,000’ | 10,000’ |

CF353C | 34 | 36 | 37 | 38 | 41 |

CF357C | 34 | 36 | 37 | 38 | 41 |

CF503C | 3.4mm | 31 | 31 | 32 | 35 |

CF557C | 29 | 30 | 30 | 31 | 32 |

CF653C | 26 | 27 | 28 | 29 | 30 |

ORDER KIT #49840

L.P. GAS

SPECIFIC ELEVATIONS

Pilot Adj.

Screw

HONEYWELL VR8200H SERIES

STANDING PILOT

FIGURE

Pilot Adj.

Screw

HONEYWELL VR8204H SERIES

I.I.D. PILOT

FIGURE

Model | 0 to | 2,000 - | 4,000 - | 6,000 - | 8,000 - |

No. | 2,000’ | 4,000’ | 6,000’ | 8,000’ | 10,000’ |

CF354C | 50 | 52 | 52 | 53 | 54 |

CF358C | 50 | 52 | 52 | 53 | 54 |

CF504C | 45 | 47 | 48 | 49 | 50 |

CF558C 2.15mm | 45 | 47 | 48 | 49 | |

CF654C | 42 | 43 | 44 | 45 | 47 |

ORDER KIT #49840 | |||||

|

|

|

|

|

|

The appliance is orificed at the factory for elevations up to 2,000 feet. If installed above 2,000 feet, the BTU input must be reduced 4% per 1,000 feet. See the following orifice chart for the proper orifice for a specific elevation.

PILOT ADJUSTMENT

Locate the pilot adjustment screw on the valve. The pilot flame should surround at least the top 3/8” of the powerpile (pilot generator) or flame sensor (see Figure 8). The pilot is unregulated so it will be operating at inlet line pressure (maximum 7” w.c. for Natural Gas and 11” w.c. for Propane Gas). To decrease the pilot flame, turn the screw clockwise (approximately six full turns to bottom of pilot light channel) until you produce sufficient flame at the minimum noise level.

PILOT FLAME ADJUSTMENT

3/8” TO 1/2” |

3/8” TO |

1/2” |

STANDING PILOT |

| I.I.D. PILOT |

FIGURE |

|

PILOT FLAME SHOULD ENVELOP 3/8 TO ½ INCH | Page 9 |

OF THE TIP OF THE GENERATOR. |