P 2/ 25

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

< Note in repair>

*Repair the tool always with gloved hand

*Blades must be covered by Blade cover

*Cool down the engin first before repairing to avoid a skin burn.

*Remove all fuels from fuel tank and carburetor. Avoid any fire from the work shop.

*Repair the tool on the stable work table and keep dust out.

*Record where and how the parts were assembled to avoid

*The dismantled parts must be treated carefully and washed clean before reassembling.

*Use Impact driver in case bolts or screws can not be loosen by hand.

*The bolts or screws must be tightened to the designated fastening torque.

*Check the movement, sound and alignment of the main parts just after assembled.

*Replace the removed gasket with the new one.

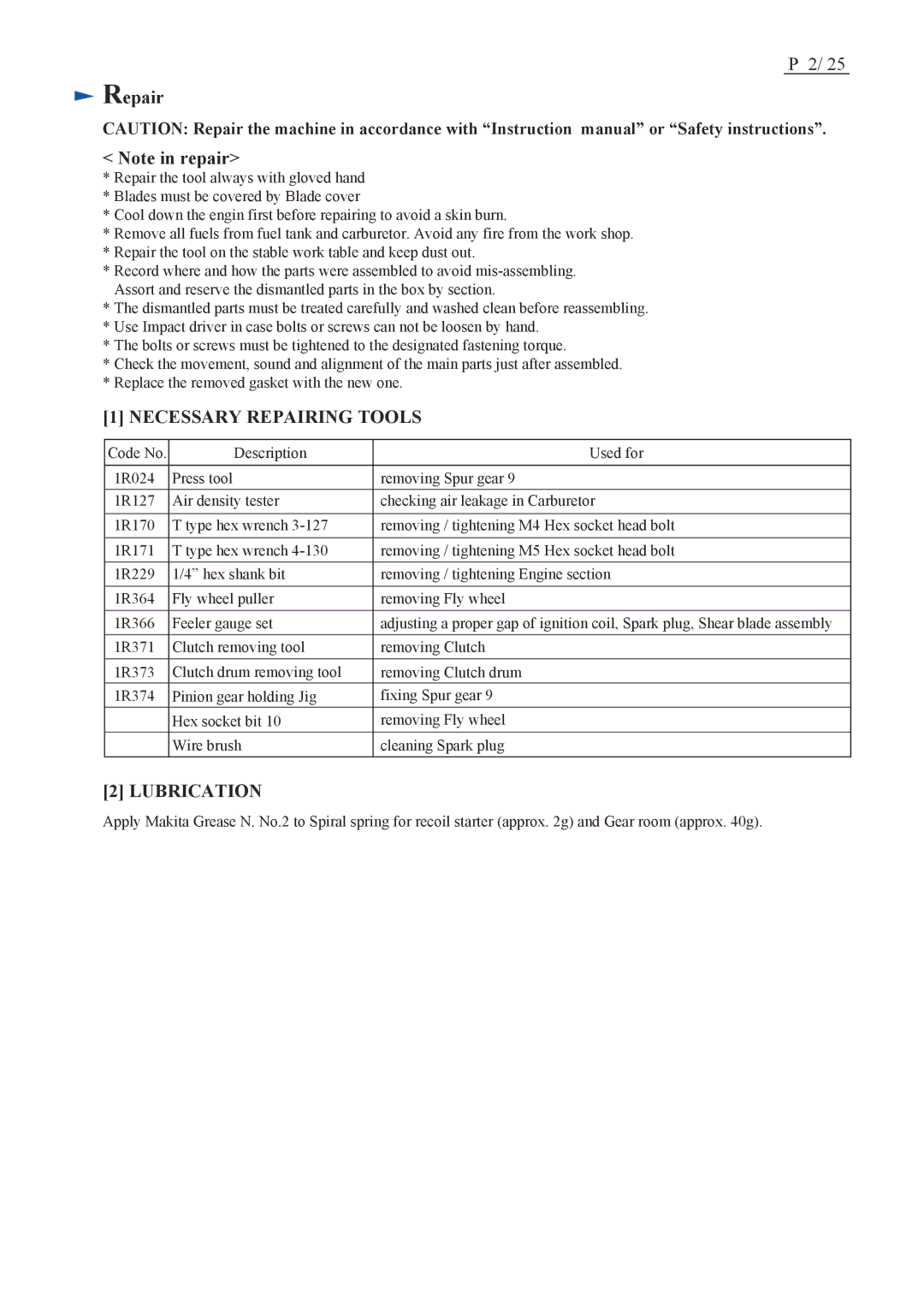

[1] NECESSARY REPAIRING TOOLS

Code No. | Description | Used for |

1R024 | Press tool | removing Spur gear 9 |

1R127 | Air density tester | checking air leakage in Carburetor |

|

|

|

1R170 | T type hex wrench | removing / tightening M4 Hex socket head bolt |

|

|

|

1R171 | T type hex wrench | removing / tightening M5 Hex socket head bolt |

|

|

|

1R229 | 1/4” hex shank bit | removing / tightening Engine section |

|

|

|

1R364 | Fly wheel puller | removing Fly wheel |

1R366 | Feeler gauge set | adjusting a proper gap of ignition coil, Spark plug, Shear blade assembly |

1R371 | Clutch removing tool | removing Clutch |

|

|

|

1R373 | Clutch drum removing tool | removing Clutch drum |

1R374 | Pinion gear holding Jig | fixing Spur gear 9 |

| Hex socket bit 10 | removing Fly wheel |

| Wire brush | cleaning Spark plug |

[2] LUBRICATION

Apply Makita Grease N. No.2 to Spiral spring for recoil starter (approx. 2g) and Gear room (approx. 40g).