3.This is where you’ll need to get help from a friend if you don’t know how to solder. Read this description fully before starting.

4.Using your soldering iron, and

5.With most of the solder removed,

Be careful not to burn your friend (perhaps they should be wearing heavy work gloves just in case..). I don’t have a picture of this since it required all my hands and fingers to get it off, leaving none for the camera.

6.With the cap removed, if there is an open hole, great. If there is still solder in the hole, find a toothpick, re- heat the hole till the solder melts, then gently stick the wooden toothpick through the hole, remove the soldering iron and let it cool. Once the solder hardens, remove the toothpick. Remember that just because the solder is hard does not make if safe to touch – it’s still quite hot. Blowing on it speeds the cooling process..

7.You should be left with 4 holes in the PCB and 2 caps apart from the PCB.

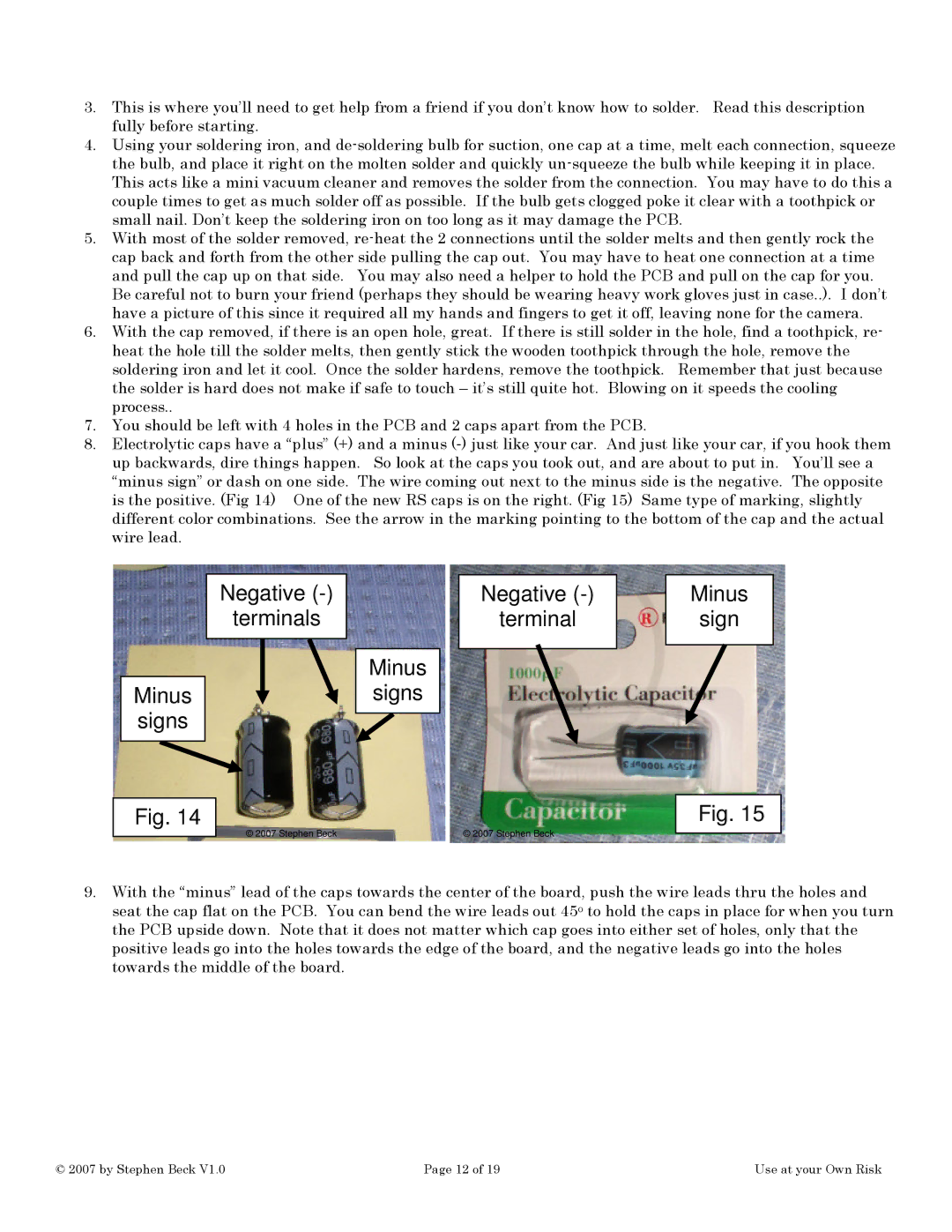

8.Electrolytic caps have a “plus” (+) and a minus

Minus signs

Fig. 14

Negative (-)

terminals

© 2007 Stephen Beck

Minus

signs

Negative (-)

terminal

© 2007 Stephen Beck

Minus

sign

Fig. 15

9.With the “minus” lead of the caps towards the center of the board, push the wire leads thru the holes and seat the cap flat on the PCB. You can bend the wire leads out 45o to hold the caps in place for when you turn the PCB upside down. Note that it does not matter which cap goes into either set of holes, only that the positive leads go into the holes towards the edge of the board, and the negative leads go into the holes towards the middle of the board.

© 2007 by Stephen Beck V1.0 | Page 12 of 19 | Use at your Own Risk |