ENGLISH

60

61

•For narrow workpieces fit the work clamp in the front hole (61) of the saw base.

7.8Mains Connection

BDanger! High voltage

•Operate this machine in dry sur- roundings only.

•Operate the machine only on a power source meeting the follow- ing requirements (see also "Tech- nical Specifications"):

−mains voltage and system fre- quency conform to the voltage and frequency shown on the machine´s nameplate;

−fuse protection by a residual current operated device (RCD) of 30 mA sensitivity;

−Outlets properly installed, earthed, and tested.

•Position power supply cable so it does not interfere with the work and is not damaged.

Run the power supply cable as illustrated through the groove (62). Ensure the cable has suffi- cient slack, so it will not tighten when sawing.

62

•Protect power supply cable from heat, aggressive liquids and sharp edges.

•Use only

sion cables of sufficient lead

•Do not pull on power supply cable to unplug.

24

8. Operation

ADanger!

•Before starting any work, check to see that the safety devices are in proper working order.

•Use personal protection gear.

•Assume proper operating posi- tion:

−at the front of the saw;

−in front of the saw;

−to the side of the line of cut.

•Risk of crushing! When tilting the sawhead, keep your hands out of the track arm holder's tilting range! Hold at the sawhead.

•If the type of work requires, use the following:

−work support – for long stock, which would otherwise fall off the table on completion of the cut;

−dust extractor.

•Cut only stock of dimensions that allow for safe and secure holding while cutting.

•Use an auxiliary fence if small cutoffs will result when cutting.

•Always hold the workpiece down on the table and do not jam it. Do not attempt to stop the saw blade by exerting lateral pressure. Risk of injury if the saw blade is blocked.

8.1Standard Cross Cuts

Maximum workpiece cross section (dimensions in mm):

Width approx. | 255 |

|

|

Height approx. | 60 |

|

|

Starting position:

−Transport locking pin pulled out.

−Sawhead fully raised.

−Cutting depth limiter set to maxi- mum depth of cut.

−Rotating table in 0° position, the lock screw of the rotating table is tight- ened.

−Motorhead in vertical (90°) position, bevel tilt locking lever tightened.

−Track arm not extended.

−Lock screw of the track arm loos- ened (if workpiece width requires).

Cutting the workpiece:

1.Hold workpiece against the fence.

2.Push the safety lock to the side and press and hold the ON/OFF switch.

3.Slowly swing the sawhead fully down, holding the handle firmly.

A Caution!

When sawing exert only mod- erate downward pressure on the saw- head, so the motor speed is not reduced too much, otherwise the motor may be overloaded and dam- aged.

4.On wider workpieces pull the saw- head forward (towards the opera- tor).

5.Cut workpiece in a single pass.

6.Release the ON/OFF switch and let the sawhead slowly return to its upper starting position.

7.Return the sawhead to the rear posi- tion.

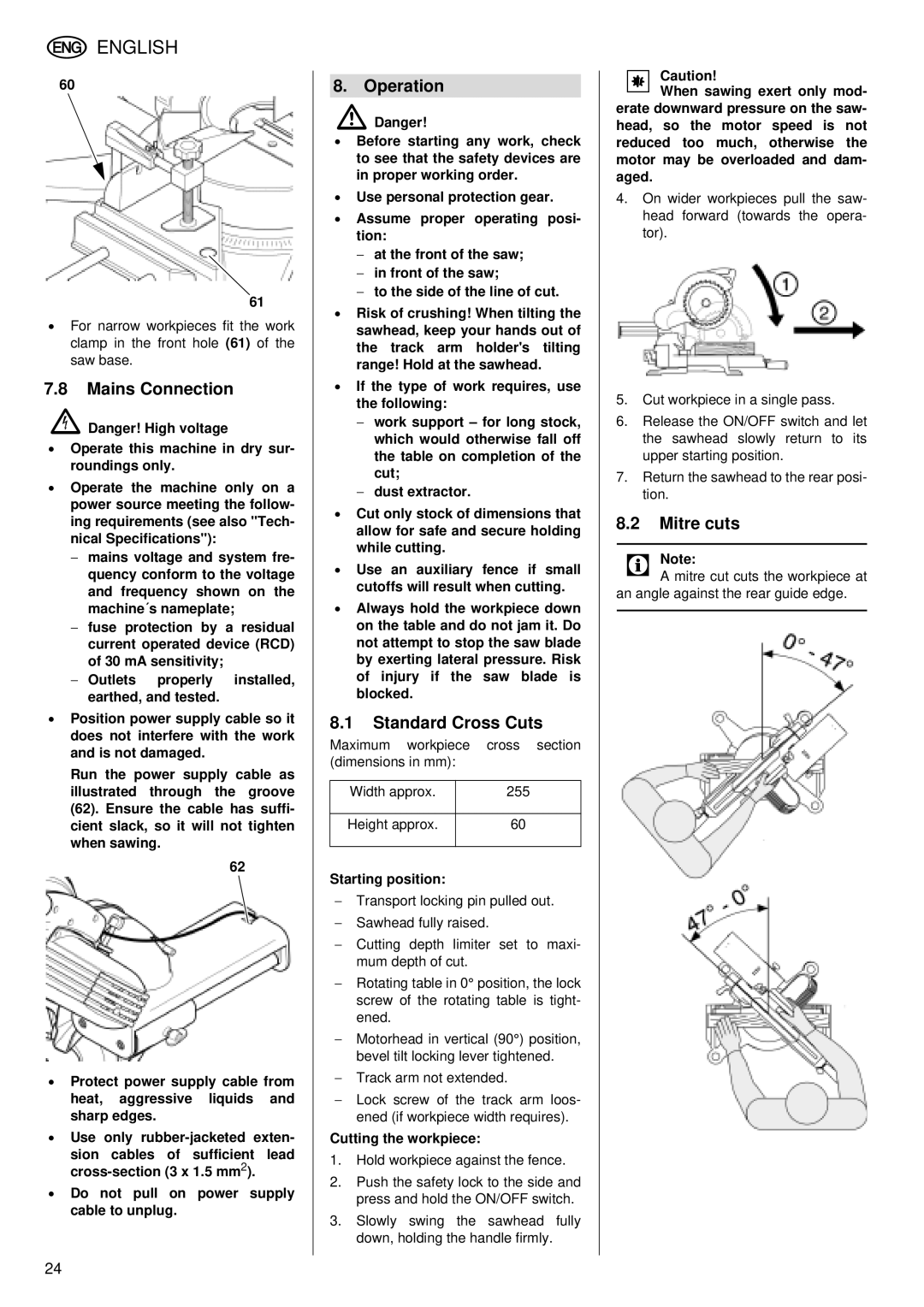

8.2Mitre cuts

3 Note:A mitre cut cuts the workpiece at an angle against the rear guide edge.