Read instructions.

Do not reach into the run- ning saw blade.

Wear safety goggles and hearing protection.

Do not operate tool in moist or wet environment.

Danger!

Avoid direct eye contact with the laser beam.

Do not carry tool at the handle; the han- dle is not designed to bear the weight of the tool.

Information on the nameplate:

30 ![]()

31

32 ![]()

33 ![]()

34 | 35 | 36 | 37 |

(30)Manufacturer

(31)Serial number

(32)Machine designation

(33)Motor specifications (see also “Technical Specifications”)

(34)Date of manufacture

(35)

(36)Waste disposal symbol – Machine can be disposed of by returning it to the manufacturer

(37)Dimensions of permissible saw blades

3.4Safety Devices

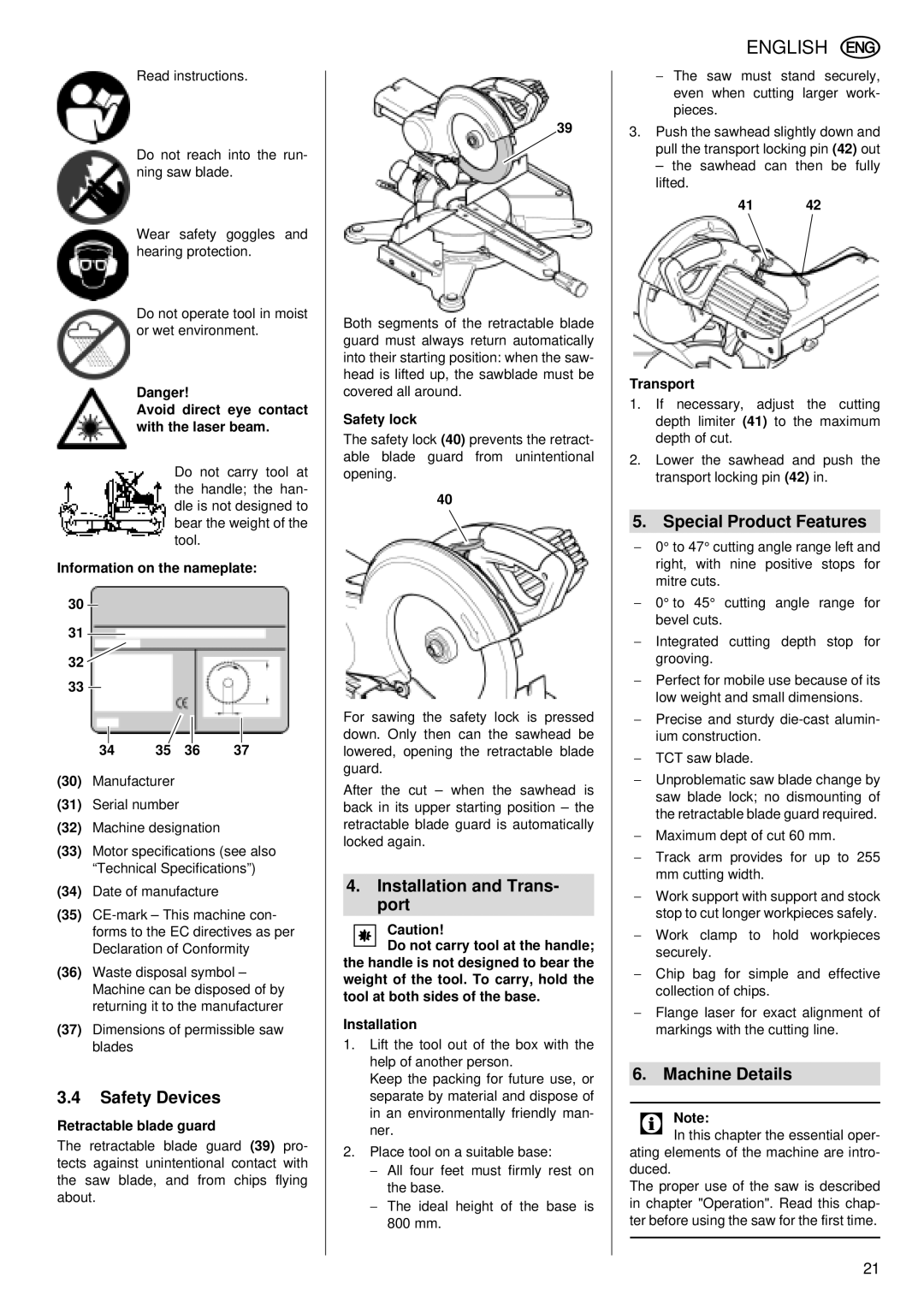

Retractable blade guard

The retractable blade guard (39) pro- tects against unintentional contact with the saw blade, and from chips flying about.

39

Both segments of the retractable blade guard must always return automatically into their starting position: when the saw- head is lifted up, the sawblade must be covered all around.

Safety lock

The safety lock (40) prevents the retract- able blade guard from unintentional opening.

40

For sawing the safety lock is pressed down. Only then can the sawhead be lowered, opening the retractable blade guard.

After the cut – when the sawhead is back in its upper starting position – the retractable blade guard is automatically locked again.

4.Installation and Trans- port

A Caution!

Do not carry tool at the handle; the handle is not designed to bear the weight of the tool. To carry, hold the tool at both sides of the base.

Installation

1.Lift the tool out of the box with the help of another person.

Keep the packing for future use, or separate by material and dispose of in an environmentally friendly man- ner.

2.Place tool on a suitable base:

−All four feet must firmly rest on the base.

−The ideal height of the base is 800 mm.

ENGLISH

−The saw must stand securely, even when cutting larger work- pieces.

3.Push the sawhead slightly down and pull the transport locking pin (42) out

– the sawhead can then be fully lifted.

41 42

Transport

1.If necessary, adjust the cutting depth limiter (41) to the maximum depth of cut.

2.Lower the sawhead and push the transport locking pin (42) in.

5.Special Product Features

−0° to 47° cutting angle range left and right, with nine positive stops for mitre cuts.

−0° to 45° cutting angle range for bevel cuts.

−Integrated cutting depth stop for grooving.

−Perfect for mobile use because of its low weight and small dimensions.

−Precise and sturdy

−TCT saw blade.

−Unproblematic saw blade change by saw blade lock; no dismounting of the retractable blade guard required.

−Maximum dept of cut 60 mm.

−Track arm provides for up to 255 mm cutting width.

−Work support with support and stock stop to cut longer workpieces safely.

−Work clamp to hold workpieces securely.

−Chip bag for simple and effective collection of chips.

−Flange laser for exact alignment of markings with the cutting line.

6. Machine Details

3 Note:In this chapter the essential oper- ating elements of the machine are intro- duced.

The proper use of the saw is described in chapter "Operation". Read this chap- ter before using the saw for the first time.

21