Page

Middleby Marshall, Inc

Technical service Manual

Table of Contents

Table of Contents

GAS Oven Sequence of Operation

Section Sequence of Operation

Sequence of Operation

Sequence of Operation

Types of Heat Transfer

Blowers, belts and pulleys

II. Blowers and Blower Speed

PS200-series PS360-series

PS300/350 air finger with shutter plate

Air finger operation

Current standard air finger all oven models

III. AIR Fingers

Performing a Test Bake

Configuration and Alignment

3D air finger label if present

Front-to-back uneven bake

PS300/350 Air Finger Shutter Adjustment

Do not

PS300/350-style air finger with adjustable shutter plate

Conveyor Speed and Bake Time

IV. Oven Capacity

Belt Time

Time of Delivery TOD

Current-style speed controller

Original-style speed controller

Conveyor Speed Controller and Drive Motor

Part Number Reference Speed Controllers

Part Number Reference Pickup Assemblies

Current-style pickup assembly see Figures

Preparing to Service the Speed Controller

Current pickup assembly End view

Current pickup assembly side view

Field Tester for Conveyor Drive Motor

Controller/Motor Failure

If the Gear Motor Runs AT Full Speed

Basic Troubleshooting Flowcharts

If the Gear Motor will not RUN AT ALL

Check the magnetic pickup on the motor

Initial Troubleshooting

Connections for pickup test

Unshielded Pickup Wires on Early PS360-series ovens

Conveyor Control Pickup Test Conveyor Motor Test

Replacing the Magnetic Pickup

Appendices

Servicing Components

Servicing Components

Servicing Components

Servicing Components

Servicing Components

Servicing Components

General

Subject

Application

Compatibility

Conveyor Speed Controller Kit for PS200R68-series ovens

Bulletin No. MM-189

II. Temperature Controller

28071-0012 a

Part Number Reference Temperature Controllers

28071-0018 a

34983 B

COM

Description

Digital Temperature Controller

Controller Types

Before you Begin

Electrical Connections

Variable Pulse Output System

Jumper Setting

Temperature

Diagnostic Error Messages

Digital Temperature Controller Operating Instructions

Middleby Corporation Service Hotline

Servicing Components

Servicing Components

III. High Limit Control Module

Operation and Troubleshooting

Part Number Reference High Limit Control Mod- ules

Location

High Limit Conversion Kit for PS300, 310, 350, & 360 Ovens

Appendix Instructions for Service Kit

Installation

Not to Scale

For Ovens with an Analog Temperature Controller

For Ovens with a Digital Temperature Controller

Testing the Installation

United Electric Model

Ovens with a cooldown feature Replacement

Ovens without a cooldown feature Replacement

Middleby Corporation Service Hotline

IV. Thermocouples

Troubleshooting

Part Number Reference Thermocouples

Thermocouple Functions

Servicing Components

Oven Thermocouple Kit

PS200 Series before 2/96, serial numbers before ASH-0001

Thermocouple Wiring PS360 Series

Analog Temperature Controller Digital

PS536

Thermocouple Wiring PS555

PS555 Electric and PS555E

Servicing Components

High limit thermocouple

High limit thermocouple Position for ovens with

Thermocouple Wiring PS570S Late Left to Right Conveyor

Thermocouple Wiring PS555G and PS570G

Current PS200 indirect drive assembly

Early-style PS200 indirect drive assembly

Blower motor fuses

Blowers

Repositioning the blower motor

Bearing lubrication

Blower belt tension

Fan shaft alignment tool

Qty Part Number Description

Four-point alignment test for correct pulley alignment

Also available

PS360-series ovens

Blower motor fuses single-phase motors

Blower motor fuses three-phase motors

Inlet ring Blower wheel puller tool

Clockwise blower wheel

PS555/570-series ovens

PS570/570S blower configuration

Pizza Hut

Standard

Intl. Tricon

Domino’s Q

PS500-series blower wheel orientation

Blower belt tension Repositioning the blower motor

Bearing replacement and alignment

Part Number Reference Blower Centrifugal Switch

VI. Blower Motor Centrifugal Safety Switch PS360-SERIES

Air pressure safety switch models

PS360WB70/EWB with Wayne burner

PS360WB70/EWB with Midco burner

Servicing Components

Servicing Components

Servicing Components

Servicing Components

IX. PS570/570S Flame Gate

PS570/570S flame gate adjustment

Part Number Reference Flame Gate

Flame Gate Orientation

PS310, PS314, PS360 or PS360WB gas train

PS200-series gas train

GAS Train and Burner System

Part Number Reference

PS360EWB or PS360WB70 gas train with Wayne burner

PS360EWB or PS360WB70 gas train with Midco burner

PS570G or PS555 gas train

PS570S gas train

Part Number Reference Gas Orifices and Gas Conversion Kits

Wayne burner exploded view

Solenoid valve vs. Modulating valve

Component Identification

Burner type

Flame targets

Pilot/Ignitor Assembly

End of burner without flame target Showing pilot shield

Flame Rectification

Flame structure

Voltage

Gas Pressure

Temperature

Air shutter adjustment

Pilot Application

Burner Blower Motor

Burner Transformer

Low Flame Bypass Orifice

Burner Motor Relay

High Flame Solenoid Valve if so equipped

Modulating Gas Valve if so equipped

Pilot pressure

Burrs in pilot adjustment portal

Combination Gas Control Valve

Ignition Module

Gas Conversion Kits

Burner and Gas Train Troubleshooting

100

Combination Gas Valve

Voltage Checks for Ignition Module Combination Gas Valve

101

102

Component Checks Reset System After Lockout

Check Spark Ignition Circuit

Check Spark Ignitor

103

Troubleshooting Flowcharts

104

105

106

107

108

Appendix Instructions for Service Kit 30185 Pilot Tee, 3/94

109

110

111

112

113

114

115

116

Appendix Instructions for Service Kit Ignition Module, 11/90

117

118

Appendix Instructions for All Gas Conversion Kits

119

120

English

121

Preparation and Disassembly

IV. Pilot Orifice Conversion

122

VII. GAS Leak Test VIII. Inlet Pressure Check

123

124

Manifold Pressure Adjustment

For Ovens with Wayne Burner, Propane to Natural Gas, 8/00

125

126

NUTS.3

127

128

129

IX. Pilot Pressure Adjustment

130

Preparation

Pilot Orifice Replacement

131

LOW Flame Orifice Replacement PS360WB70 only

Main Orifice Replacement

132

GAS Leak Test

Main Manifold Pressure Adjustment

Pilot Pressure Adjustment

133

Inlet Pressure Check

Conversion Labeling

134

Propane

36856

135

Propane to Natural Gas Installation Instructions

136

137

14 W.C./34.9mbar

138

Natural

139

140

PS200 electric early with mercury Contactors and fuses

XI. Electric Oven Heating System

Part No. Description

Individual element electrical data

Removing elements

141

PS310/360-series ovens

Electrical leads disconnected

142

143

Element bank removed spacer bracket visible

PS555 ovens

144

145

PS555 electric oven heating element removal

146

Mercury Contactor Replacement

147

148

149

Component Wiring

150

II. PS200-SERIES Ovens

151

152

153

154

155

156

157

158

159

160

III. PS360-SERIES Ovens Electrical Wiring Diagrams

161

162

163

164

165

166

III. PS555/570-SERIES Ovens Electrical Wiring Diagrams

167

168

169

170

171

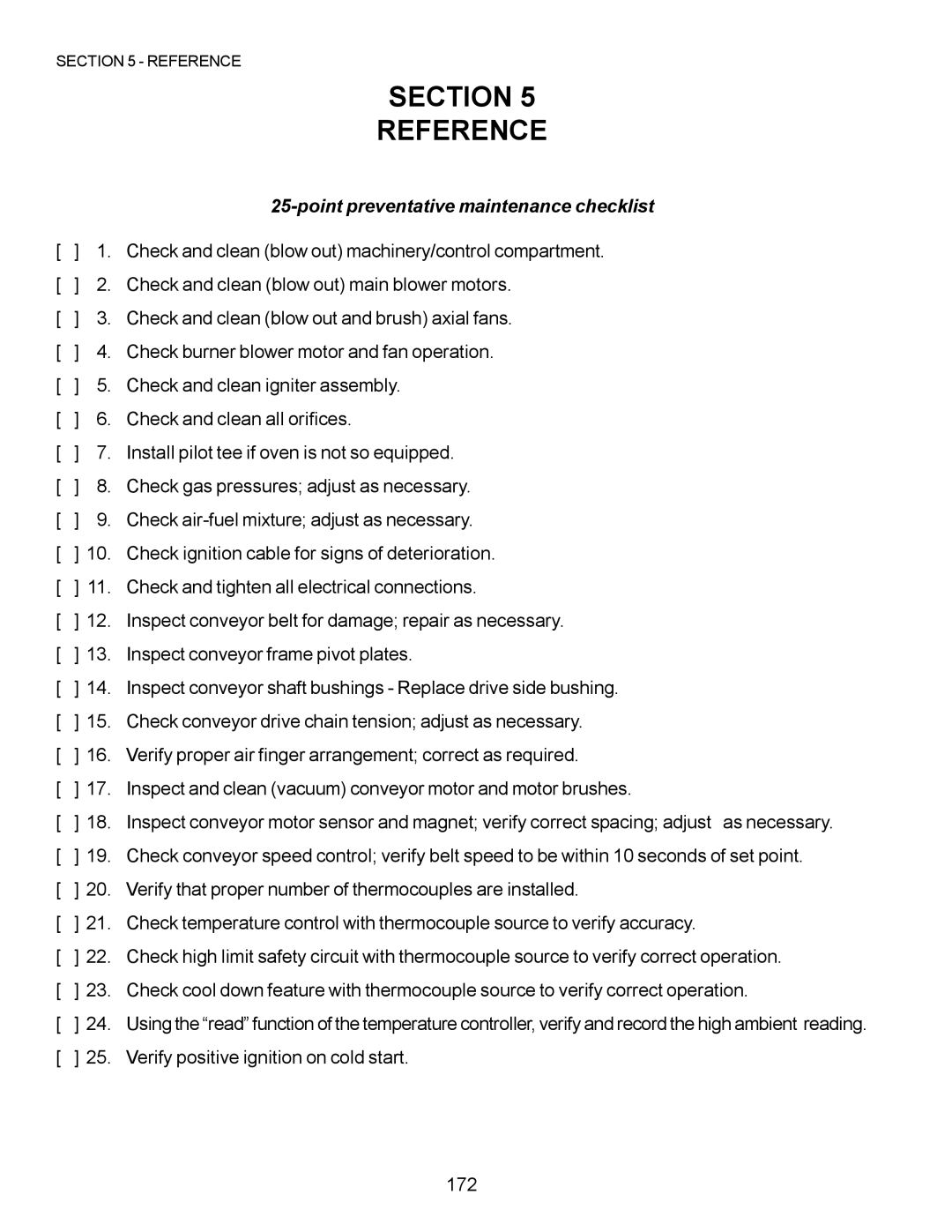

Check and clean blow out main blower motors

Check and clean blow out machinery/control compartment

Check and clean blow out and brush axial fans

Check and clean igniter assembly

173

Multiply To Obtain

174

175

Pressure conversion chart

176

177

178

179

180