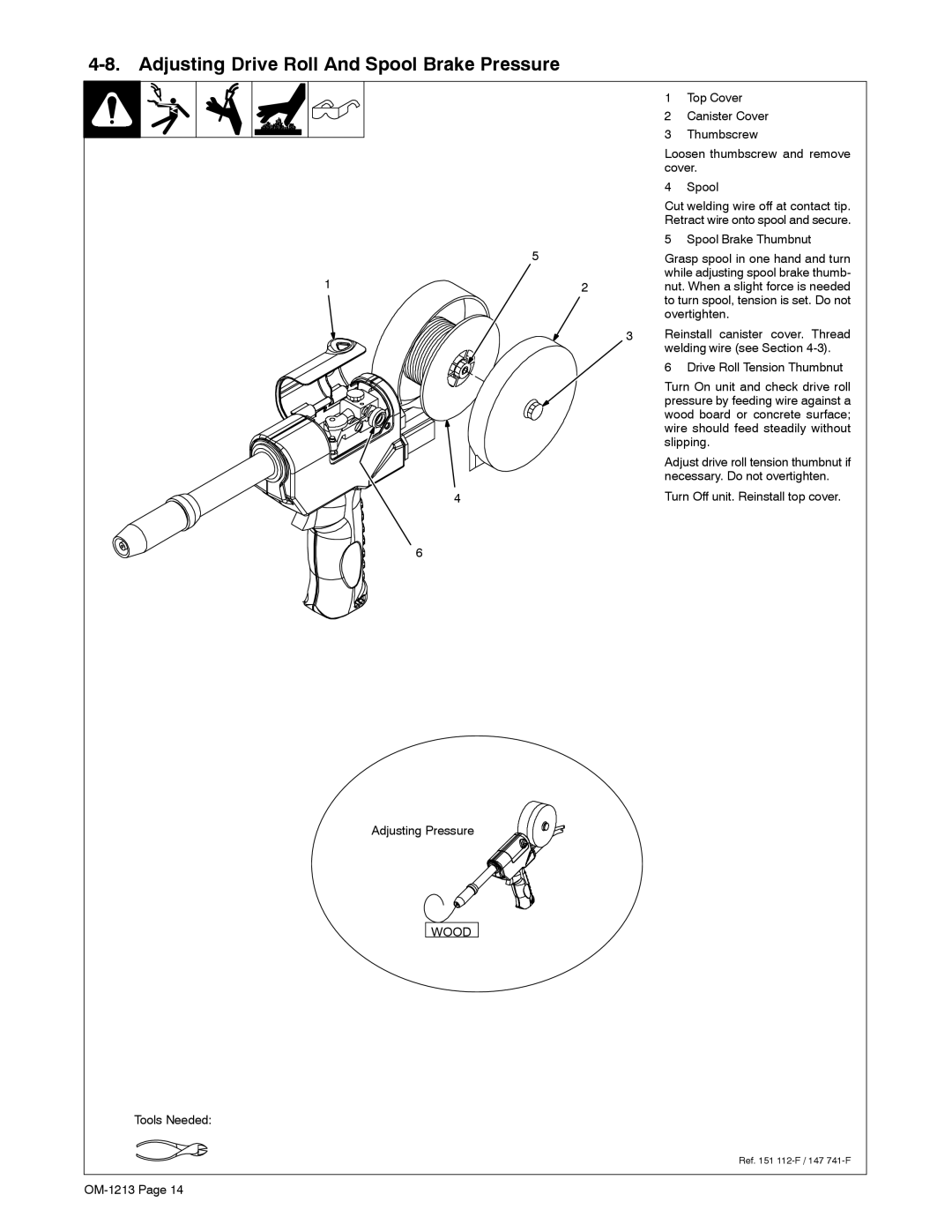

4-8. Adjusting Drive Roll And Spool Brake Pressure

|

| 1 | Top Cover |

|

| 2 | Canister Cover |

|

| 3 | Thumbscrew |

|

| Loosen thumbscrew and remove | |

|

| cover. | |

|

| 4 | Spool |

|

| Cut welding wire off at contact tip. | |

|

| Retract wire onto spool and secure. | |

|

| 5 | Spool Brake Thumbnut |

| 5 | Grasp spool in one hand and turn | |

1 |

| while adjusting spool brake thumb- | |

2 | nut. When a slight force is needed | ||

|

| to turn spool, tension is set. Do not | |

|

| overtighten. | |

| 3 | Reinstall canister cover. Thread | |

|

| welding wire (see Section | |

|

| 6 | Drive Roll Tension Thumbnut |

|

| Turn On unit and check drive roll | |

|

| pressure by feeding wire against a | |

|

| wood board or concrete surface; | |

|

| wire should feed steadily without | |

|

| slipping. | |

|

| Adjust drive roll tension thumbnut if | |

|

| necessary. Do not overtighten. | |

| 4 | Turn Off unit. Reinstall top cover. | |

| 6 |

|

|

Adjusting Pressure

WOOD

Tools Needed:

Ref. 151