.A complete Parts List is available at www.MillerWelds.com

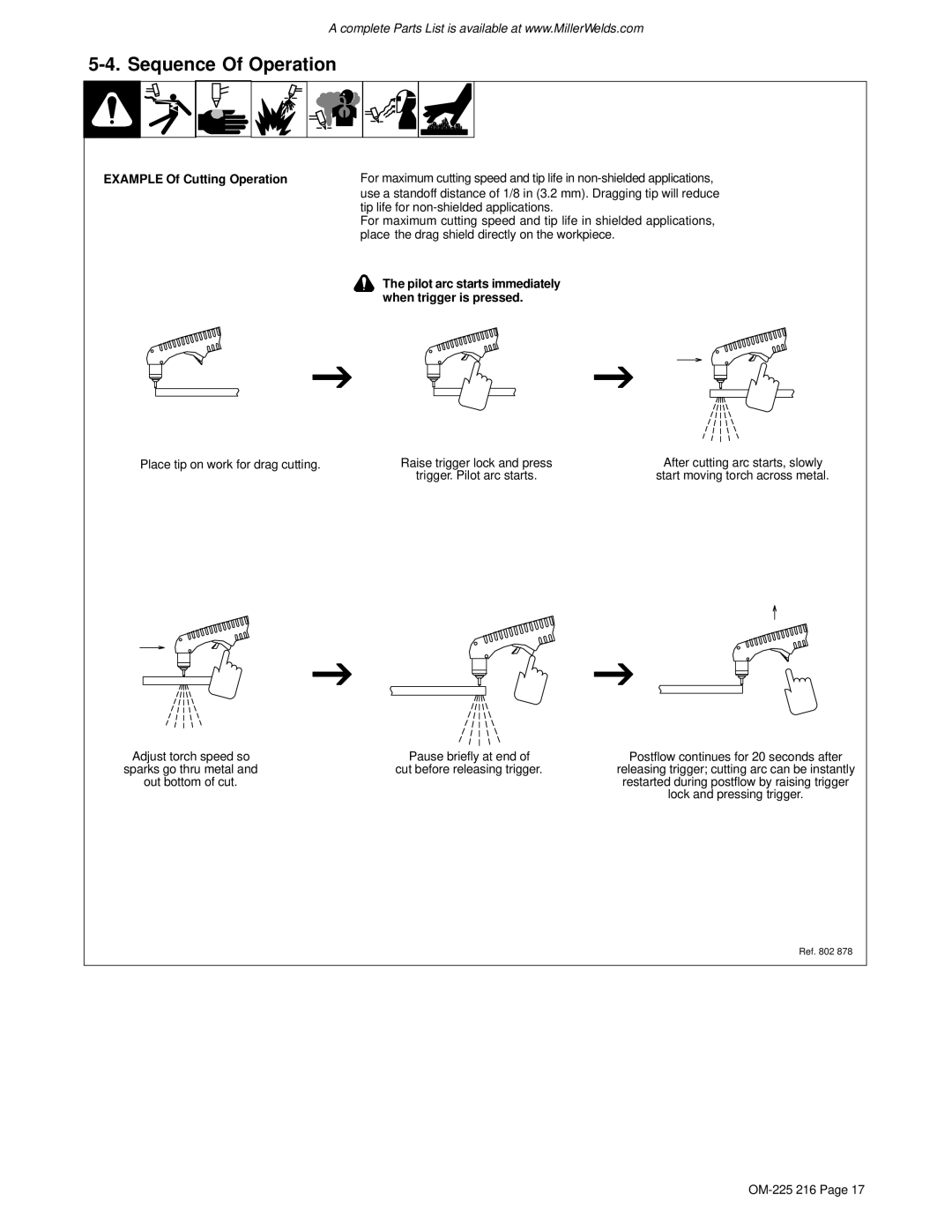

5-4. Sequence Of Operation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXAMPLE Of Cutting Operation | . For maximum cutting speed and tip life in | ||||||||||||

|

|

|

|

|

| use a standoff distance of 1/8 in (3.2 mm). Dragging tip will reduce | |||||||

|

|

|

|

|

| tip life for | |||||||

|

|

|

|

|

| For maximum cutting speed and tip life in shielded applications, | |||||||

|

|

|

|

|

| place the drag shield directly on the workpiece. | |||||||

|

|

|

|

|

|

| The pilot arc starts immediately | ||||||

|

|

|

|

|

|

| when trigger is pressed. | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Place tip on work for drag cutting. | Raise trigger lock and press | After cutting arc starts, slowly |

| trigger. Pilot arc starts. | start moving torch across metal. |

Adjust torch speed so | Pause briefly at end of | Postflow continues for 20 seconds after |

sparks go thru metal and | cut before releasing trigger. | releasing trigger; cutting arc can be instantly |

out bottom of cut. |

| restarted during postflow by raising trigger |

|

| lock and pressing trigger. |

Ref. 802 878