| Item | Dia. | Part | Description | Quantity |

| No. | Mkgs. | No. |

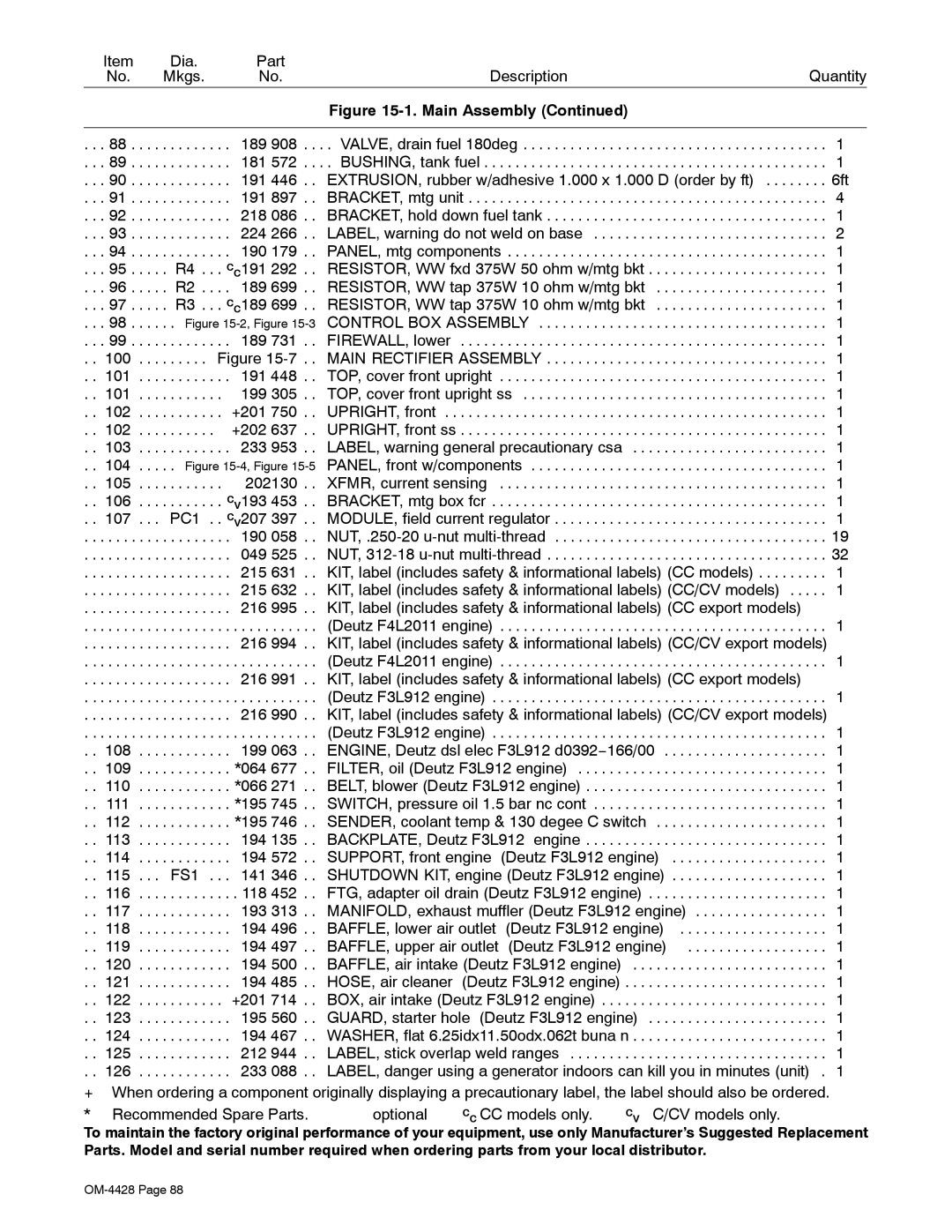

| | | | Figure 15-1. Main Assembly (Continued) | | |

| | | | | |

. . . 88 . | . . . . . . . . . | . . . 189 908 . . . | . VALVE, drain fuel 180deg | . . . | 1 |

. . . 89 . | . . . . . . . . . | . . . 181 572 . . . | . BUSHING, tank fuel . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . . 90 . | . . . . . . . . . | . . . 191 446 . . | EXTRUSION, rubber w/adhesive 1.000 x 1.000 D (order by ft) | . . . | 6ft |

. . . 91 . | . . . . . . . . . | . . . 191 897 . . | BRACKET, mtg unit . . . . | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 4 |

. . . 92 . | . . . . . . . . . | . . . 218 086 . . | BRACKET, hold down fuel tank | . . . | 1 |

. . . 93 . | . . . . . . . . . | . . . 224 266 . . | LABEL, warning do not weld on base | . . . | 2 |

. . . 94 . | . . . . . . . . . | . . . 190 179 . . | PANEL, mtg components | . . . | 1 |

. . . 95 . | . . . . R4 . | . . CC191 292 . . | RESISTOR, WW fxd 375W 50 ohm w/mtg bkt | . . . | 1 |

. . . 96 . | . . . . R2 . | . . . 189 699 . . | RESISTOR, WW tap 375W 10 ohm w/mtg bkt | . . . | 1 |

. . . 97 . | . . . . R3 . | . . CC189 699 . . | RESISTOR, WW tap 375W 10 ohm w/mtg bkt | . . . | 1 |

. . . 98 . | . . . . . Figure 15-2, Figure 15-3 | CONTROL BOX ASSEMBLY | . . . | 1 |

. . . 99 . | . . . . . . . . . | . . . 189 731 . . | FIREWALL, lower | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . 100 | . . . . . . . . . | Figure 15-7 . . | MAIN RECTIFIER ASSEMBLY | . . . | 1 |

. . | 101 | . . . . . . . . . | . . . 191 448 . . | TOP, cover front upright | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . | 101 | . . . . . . . . . | . . ♦199 305 . . | TOP, cover front upright ss | . . . | 1 |

. . 102 | . . . . . . . . . | . . +201 750 . . | UPRIGHT, front | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . 102 | . . . . . . . . . | . ♦+202 637 . . | UPRIGHT, front ss | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . 103 | . . . . . . . . . | . . . 233 953 . . | LABEL, warning general precautionary csa | . . . | 1 |

. . | 104 . . . . . Figure 15-4, Figure 15-5 | PANEL, front w/components | . . . | 1 |

. . 105 | . . . . . . . . . | . . ♦202130 . . | XFMR, current sensing | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . 106 | . . . . . . . . . | . . CV193 453 . . | BRACKET, mtg box fcr . | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . | 107 . . . PC1 | . . CV207 397 . . | MODULE, field current regulator | . . . | 1 |

. . | . . . . . | . . . . . . . . . | . . . 190 058 . . | NUT, .250-20 u-nut multi-thread | . . . | 19 |

. . | . . . . . | . . . . . . . . . | . . . 049 525 . . | NUT, 312-18 u-nut multi-thread | . . . | 32 |

. . | . . . . . | . . . . . . . . . | . . . 215 631 . . | KIT, label (includes safety & informational labels) (CC models) | . . . | 1 |

. . | . . . . . | . . . . . . . . . | . . . 215 632 . . | KIT, label (includes safety & informational labels) (CC/CV models) | 1 |

. . | . . . . . | . . . . . . . . . | . . . 216 995 . . | KIT, label (includes safety & informational labels) (CC export models) | | |

. . | . . . . . | . . . . . . . . . | . . . . . . . . . . . . . . | (Deutz F4L2011 engine) | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . | . . . . . | . . . . . . . . . | . . . 216 994 . . | KIT, label (includes safety & informational labels) (CC/CV export models) | |

. . | . . . . . | . . . . . . . . . | . . . . . . . . . . . . . . | (Deutz F4L2011 engine) | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . | . . . . . | . . . . . . . . . | . . . 216 991 . . | KIT, label (includes safety & informational labels) (CC export models) | | |

. . | . . . . . | . . . . . . . . . | . . . . . . . . . . . . . . | (Deutz F3L912 engine) . | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . | . . . . . | . . . . . . . . . | . . . 216 990 . . | KIT, label (includes safety & informational labels) (CC/CV export models) | |

. . | . . . . . | . . . . . . . . . | . . . . . . . . . . . . . . | (Deutz F3L912 engine) . | . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . | . . . | 1 |

. . 108 | . . . . . . . . . | . . . 199 063 . . | ENGINE, Deutz dsl elec F3L912 d0392−166/00 | . . . | 1 |

. . 109 | . . . . . . . . . | . . . *064 677 . . | FILTER, oil (Deutz F3L912 engine) | . . . | 1 |

. . | 110 | . . . . . . . . . | . . . *066 271 . . | BELT, blower (Deutz F3L912 engine) | . . . | 1 |

. . | 111 | . . . . . . . . . | . . . *195 745 . . | SWITCH, pressure oil 1.5 bar nc cont | . . . | 1 |

. . 112 | . . . . . . . . . | . . . *195 746 . . | SENDER, coolant temp & 130 degee C switch | . . . | 1 |

. . 113 | . . . . . . . . . | . . . 194 135 . . | BACKPLATE, Deutz F3L912 engine | . . . | 1 |

. . 114 | . . . . . . . . . | . . . 194 572 . . | SUPPORT, front engine | (Deutz F3L912 engine) | . . . | 1 |

. . 115 | . . . FS1 | . . . 141 346 . . | SHUTDOWN KIT, engine (Deutz F3L912 engine) | . . . | 1 |

. . | 116 | . . . . . . . . . | . . . . 118 452 . . | FTG, adapter oil drain (Deutz F3L912 engine) | . . . | 1 |

. . 117 | . . . . . . . . . | . . . 193 313 . . | MANIFOLD, exhaust muffler (Deutz F3L912 engine) | . . . | 1 |

. . | 118 | . . . . . . . . . | . . . 194 496 . . | BAFFLE, lower air outlet | (Deutz F3L912 engine) | . . . | 1 |

. . | 119 | . . . . . . . . . | . . . 194 497 . . | BAFFLE, upper air outlet | (Deutz F3L912 engine) | . . . | 1 |

. . 120 | . . . . . . . . . | . . . 194 500 . . | BAFFLE, air intake (Deutz F3L912 engine) | . . . | 1 |

. . 121 | . . . . . . . . . | . . . 194 485 . . | HOSE, air cleaner (Deutz F3L912 engine) | . . . | 1 |

. . 122 | . . . . . . . . . | . . +201 714 . . | BOX, air intake (Deutz F3L912 engine) | . . . | 1 |

. . 123 | . . . . . . . . . | . . . 195 560 . . | GUARD, starter hole (Deutz F3L912 engine) | . . . | 1 |

. . 124 | . . . . . . . . . | . . . 194 467 . . | WASHER, flat 6.25idx11.50odx.062t buna n | . . . | 1 |

. . 125 | . . . . . . . . . | . . . 212 944 . . | LABEL, stick overlap weld ranges | . . . | 1 |

. . | 126 | . . . . . . . . . | . . . 233 088 . . | LABEL, danger using a generator indoors can kill you in minutes (unit) . | 1 |