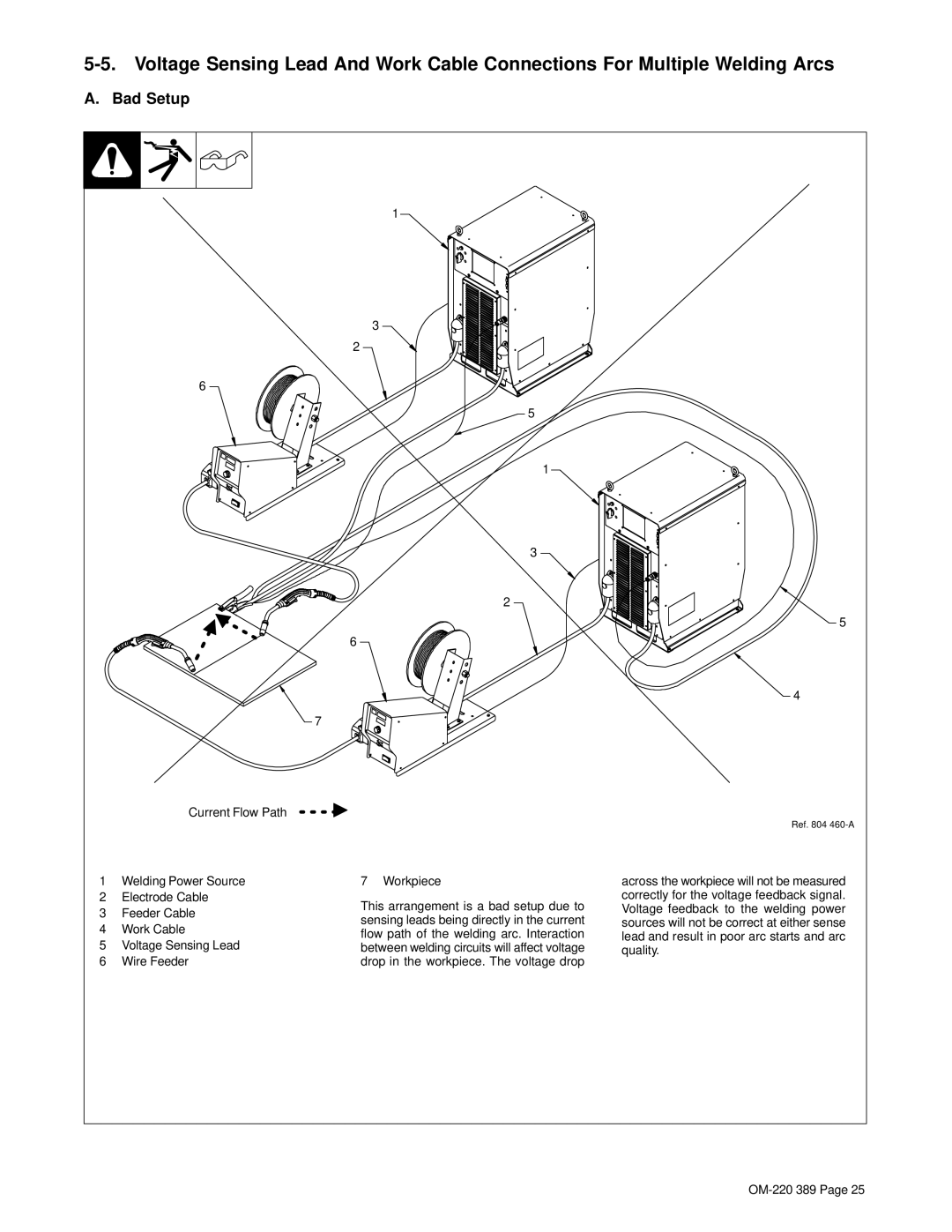

A. Bad Setup

|

| 1 | |

|

| 3 | |

|

| 2 | |

| 6 |

| |

|

| 5 | |

|

| 1 | |

|

| 3 | |

|

| 2 | |

|

| 6 | |

|

| 7 | |

| Current Flow Path |

| |

1 | Welding Power Source | 7 Workpiece | |

2 | Electrode Cable | This arrangement is a bad setup due to | |

3 | Feeder Cable | ||

sensing leads being directly in the current | |||

4 | Work Cable | ||

flow path of the welding arc. Interaction | |||

5 | Voltage Sensing Lead | ||

between welding circuits will affect voltage | |||

6 | Wire Feeder | drop in the workpiece. The voltage drop |

5

4

Ref. 804

across the workpiece will not be measured correctly for the voltage feedback signal. Voltage feedback to the welding power sources will not be correct at either sense lead and result in poor arc starts and arc quality.