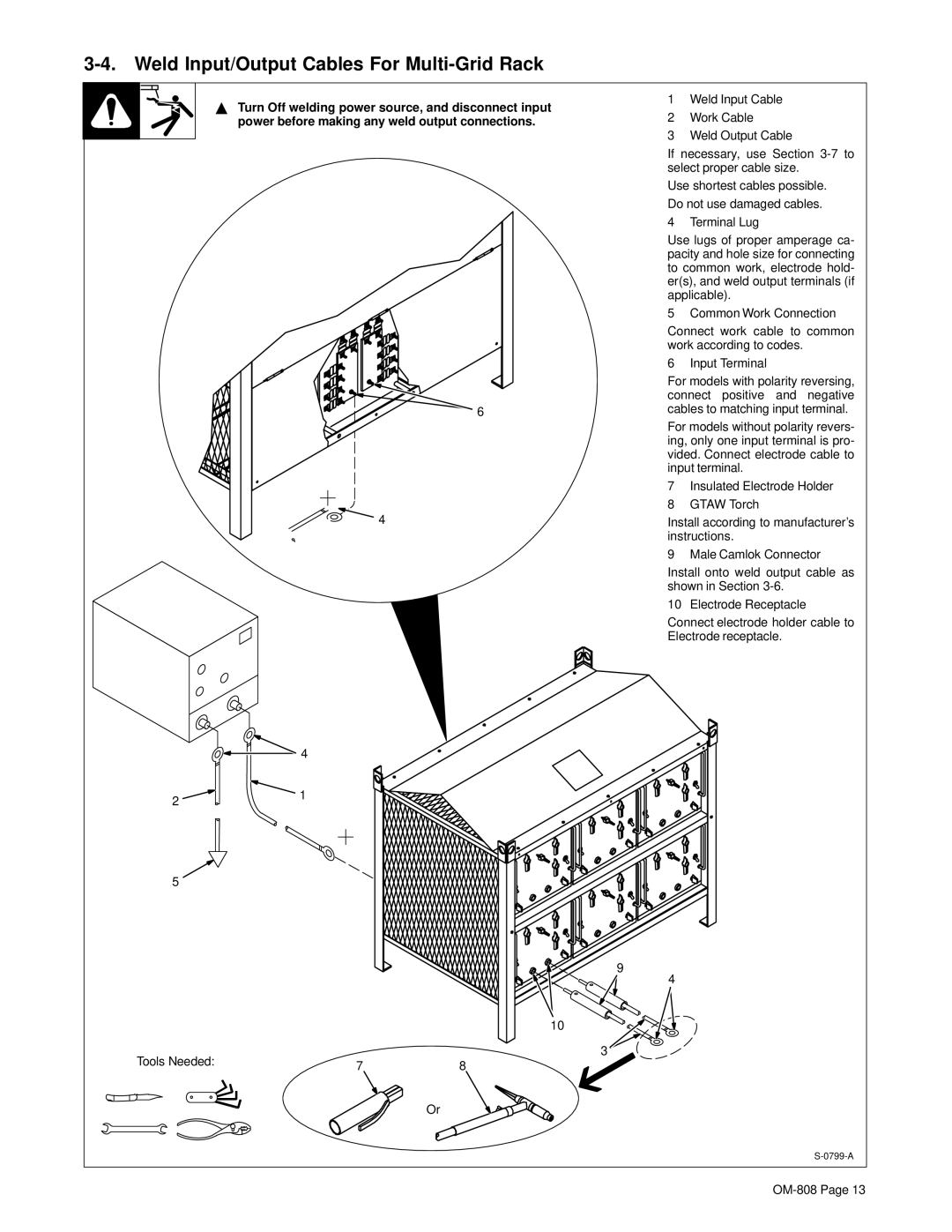

3-4. Weld Input/Output Cables For Multi-Grid Rack

2

5

Tools Needed:

Y Turn Off welding power source, and disconnect input | 1 | Weld Input Cable | |

2 | Work Cable | ||

power before making any weld output connections. | |||

| 3 | Weld Output Cable | |

| If necessary, use Section | ||

| select proper cable size. | ||

| Use shortest cables possible. | ||

| Do not use damaged cables. | ||

| 4 | Terminal Lug | |

| Use lugs of proper amperage ca- | ||

| pacity and hole size for connecting | ||

| to common work, electrode hold- | ||

| er(s), and weld output terminals (if | ||

| applicable). | ||

| 5 | Common Work Connection | |

| Connect work cable to common | ||

| work according to codes. | ||

| 6 | Input Terminal | |

| For models with polarity reversing, | ||

| connect positive and negative | ||

6 | cables to matching input terminal. | ||

| For models without polarity revers- | ||

| ing, only one input terminal is pro- | ||

| vided. Connect electrode cable to | ||

| input terminal. | ||

| 7 | Insulated Electrode Holder | |

| 8 | GTAW Torch | |

4 | Install according to manufacturer’s | ||

| instructions. | ||

| 9 | Male Camlok Connector | |

| Install onto weld output cable as | ||

| shown in Section | ||

| 10 | Electrode Receptacle | |

| Connect electrode holder cable to | ||

| Electrode receptacle. | ||

![]() 4

4

1

9

4

10

3

78

Or