|

|

| |||

Install & | Select | Put On |

| Insert | Turn On |

Connect | Electrode | Personal Safety | Set Controls | Electrode | Welding Power |

Equipment |

| Equipment |

| Into Holder | Source |

Begin Welding |

|

|

|

|

|

|

|

|

|

| ssb7.1 9/92 |

|

|

| ||||

Install & | If Applicable, | Select | Insert | Put On |

| |

Connect | Install High_ | Tungsten | Tungsten | Personal Safety | Set Controls | |

Equipment | Frequency Unit | Into Torch | Equipment |

| ||

| Turn On | If Applicable, | Turn On |

|

|

|

Shielding Gas | Turn On High- | Welding Power | Begin Welding |

| ||

|

| Frequency Unit | Source |

|

|

|

|

|

|

|

|

| ssb8.1* 12/92 |

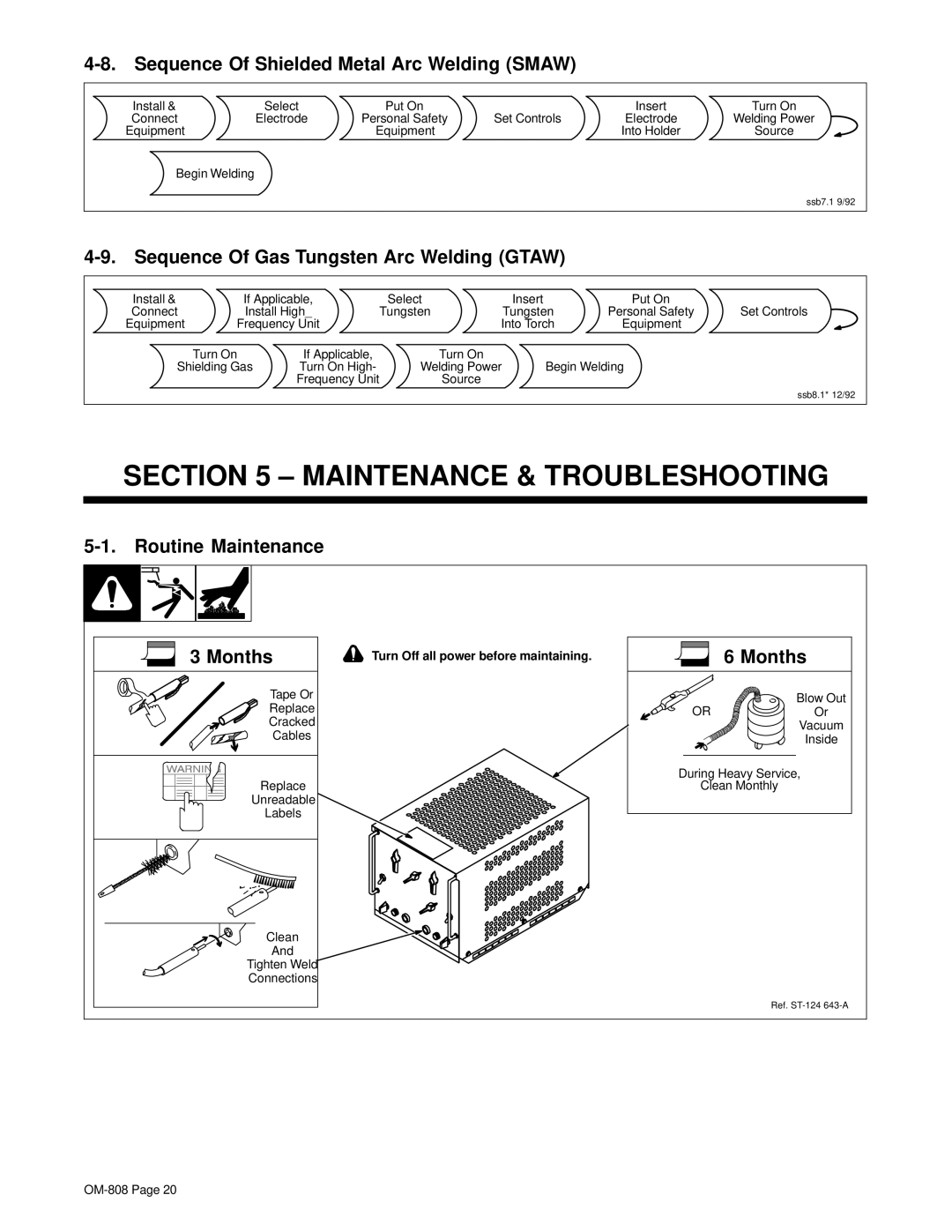

SECTION 5 – MAINTENANCE & TROUBLESHOOTING

5-1. Routine Maintenance

3 Months | Turn Off all power before maintaining. |

| 6 Months |

Tape Or |

|

| Blow Out |

Replace |

| OR | |

| Or | ||

Cracked |

|

| Vacuum |

Cables |

|

| |

|

| Inside | |

|

|

| |

|

| During Heavy Service, | |

Replace |

| Clean Monthly | |

Unreadable |

|

|

|

Labels |

|

|

|

Clean

And

Tighten Weld

Connections

Ref.