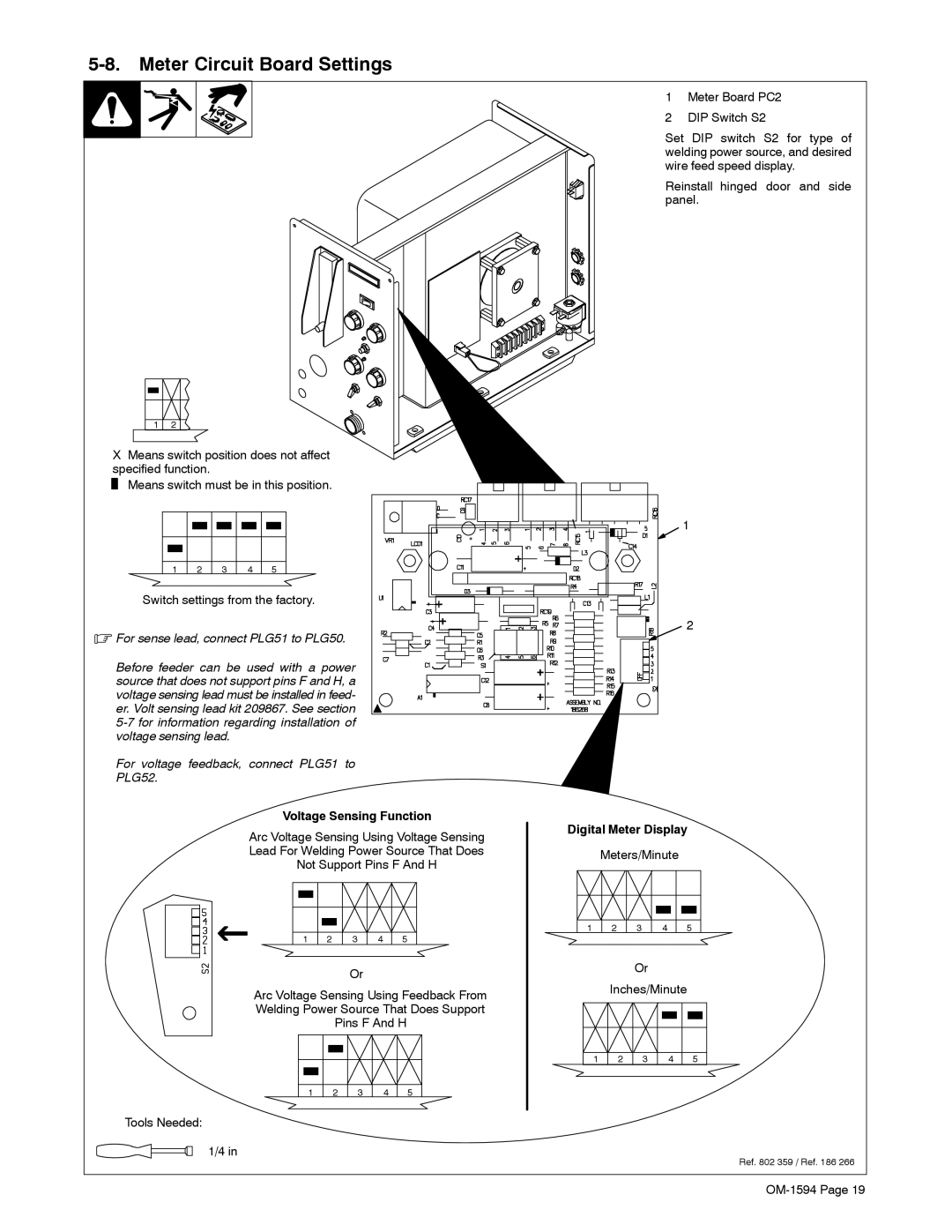

5-8. Meter Circuit Board Settings

1 2

XMeans switch position does not affect specified function.

. Means switch must be in this position.

1 2 3 4 5

Switch settings from the factory.

.For sense lead, connect PLG51 to PLG50.

Before feeder can be used with a power source that does not support pins F and H, a voltage sensing lead must be installed in feed- er. Volt sensing lead kit 209867. See section

For voltage feedback, connect PLG51 to PLG52.

Voltage Sensing Function

Arc Voltage Sensing Using Voltage Sensing

Lead For Welding Power Source That Does

Not Support Pins F And H

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

| 2 |

| 3 | 4 | 5 | ||

Or

Arc Voltage Sensing Using Feedback From

Welding Power Source That Does Support

Pins F And H

1 2 3 4 5

Tools Needed:

1/4 in

1Meter Board PC2

2DIP Switch S2

Set DIP switch S2 for type of welding power source, and desired wire feed speed display.

Reinstall hinged door and side panel.

1

2

Digital Meter Display

Meters/Minute

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 | 2 | 3 | 4 |

| 5 |

| ||

Or

Inches/Minute

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 | 2 | 3 | 4 |

| 5 | ||

Ref. 802 359 / Ref. 186 266