Service Handbook

Page

Contents

Carefully read the labels affixed to the main unit

Safety precautions

Use a vacuum pump with a reverse flow check valve

Be especially careful when managing the tools

Do not use the existing refrigerant piping

Use liquid refrigerant to seal the system

Storage of Piping Material

Reason

Piping Machining

Reasons

When non-oxide brazing was used

Brazing

Items to be strictly observed

Vacuuming

Airtightness Test

R22 leakage detector

R410A-Pink

Charging of Refrigerant

Dryer

Cylinder color identification R407C-Gray

Outdoor unit PURY-P400·500YMF-C

Appearance of Components

P400 Type P500 Type

51C2 Module IPM Board

Controller Box

Noise filter Magnetic contactor 52C1 Capacitor C2, C3 52F

Puhy / Pury

Main board

INV board

CNE CNDC1

Fancon board

Board

Cnpow Cnfan CNFC2

SNB board Board

Earth

BC controller

Cntr

SW4 SW5 SW2 SW1

Relay 10 board Relay 4 board

SV8 SV7

ACC

LEV1 SVM1

CMB-P108, 1010, 1013, 1016V-FA

LEV3 SVM2

PS3

TH25

LEV3a

TH22

PURY-P400·500YMF-C

Electrical Wiring Diagram

SV7B SV7A SV7C SV8B SV8A SV8C

CMB-P108·1010V-FA

CMB-P1013·1016V-FA

Symbol

LEV3

CMB-P108V-FB

DB/WB

Standard Operation Data

Cooling operation

PURY-P400YMF-C PURY-P500YMF-C

Heating operation

SW3

Ture Power is on Defrosting end tempera

Function of Dip SW and Rotary SW

SWU

Model P71 P80 P100 P125 P140

SW2 setting

Indoor unit DIP SW1

P40 P50 P63

SW4

220V 240V

Function

Check points before test run

Before Test Run

Connected indoor units Can be connected without a RP

Insulation pipe

Check points for test run when mounting options

Local remote controller displays code No

Built-in optional parts

Portion

Check points for system structure

Not heat at heating

Example, 200m or less total length 500m at the farthest

Error stop, compressor trouble

CN40 on the Main board when the system is centralized

Turn on power source 12 hours before starting operations?

Warm or cold air is blowing out

Test Run Method

Test RUN

Switch function

Filter +

Controlled

Description of registration/deletion/retrieval

Attribute display of unit

Group registration of indoor unit

Registration procedure

No registration

Operation procedure

Press the switch for confirmation E

Switch G for the interlocked setting mode. See figure below

Deletion completed Case of group re

Press the switch for confirmation F twice continuously

Deletion of address not existing

Compressor capacity control

Control of Outdoor Unit 1- 1 PURY-P400·500 YMF-C

Initial processing

Control at staring

OFF

Bypass capacity control

SV6a

Stop

SV1

Defrosting control

Oil return control Electronic expansion valve Slev

Judgement and control of refrigerant amount

Control of liquid level detecting heater

Outdoor unit heat exchanger capacity control

Four-way valve

Heat exchanger TH9

Accumulator CS circuit

Control at initial starting

Start of initial operation mode Step

End of initial operation mode 5 minutes Example

Initial start control timing chart

Example Minutes

400 500 No Compressor Failure 48 % 65 %

Emergency response operating mode

Control of LEV

Control of BC Controller

Control of SVA, SVB and SVC

Control of SVM1 only FA type

Outdoor unit

Operation Flow Chart

Normal operations Trouble observed Stop

Normal operations

Operation No command

BC controller

Start

Indoor unit

Test run start Thermostat on

Cooling operation

Normal operations Test run Stop

Cooling operation Way valve OFF Indoor unit fan Operations

Normal operations Defrosting operations Stop Test run

Heating operation

Same as those in cooling operations

Dry operation

Thermostat on

Thermostat on Inlet temp ˚C

MC1

List of Major Component Functions

MC2

TH6

TH3

TH4

TH5

CH3

CH2

Resistance of Temperature Sensor

Symptom

Operating Characteristics and Refrigerant Amount

Adjustment and Judgement of Refrigerant Amount

Low temperature than overload Control system Temperature

Additional Refrigerant Charge Volume

Refrigerant Volume

PURY-P400YMF-C PURY-P500YMF-C

SC11 SC16

Refrigerant Volume Adjustment Mode Operation

Procedure

TH1

Adjustment starts

YES

Turn all of switches Readjust

SW1 OFF

18 kg 27 kg 31 kg

Pipe Length Or less 60 ~ 90 m

Judging Failure

Connector GND Black Vout White Vcc DC5V Red

Principal Parts

Pressure Sensor

SV3 SV4 SV5 SV6

Solenoid Valve SV1~8

SW1

LED

Solenoid Valves Block1

CV4b

Solenoid Valves Block

SV8 CV7b

CV5b

Check Valves Block1

CV6b

CV5b CV4b CV2b CV3b

Check Valves Block2

Check Valves Block2

LEV Valve Closing and Valve Opening Operations

Outdoor LEV

Intake temperature display, it can

Temperature sensed by Thermistor liquid pipe temperature

Temperature is considerably low

Compared to the remote control’s

Part a

10~50 Ω Tester

Intelligent Power Module IPM

Diode stack

Tester ⊕

NET transmission line break on the side of the room unit

Check method and handling

After checking , if these are factors

Check voltage between a and B

Power terminal block Voltage Verify the power

INV board----CNAC2, CNVCC1, CNL2

Phenomena

Unit is removed

Main board ----CNS1, CNVCC3

CNS1, CNVCC3

Case of M-NET remote controller

30V Check Procedure

No powering signal INV board

Checking method & countermeasure Case Melans is not used

Transmission line Wiring miss Door unit M-NET 17 ~ 30V?

Normal in case of 10V ~

Melans

CNR, CNAC2

Investigation of transmission wave shape/noise

Earthing

Forwiring

Method

Checking

Vidual Parts Failure Judgment Methods

Disconnected wires should Insulation resistance 2MΩ or more

If the problem is solved and you connect

Again, replace the compressor

CNFC1~CNFC2

TB1A~NF~TB1B~CNTR1~T01~CNTR

TB1B~CNPOW, CNFAN~CN04~CNMF

CNFAN~52F~CN05~CNMF

IPM

20~60Ω AC Current sensor Acct

A1-A2

Black Capacitor C2,C3 Board Red

Motor Compressor Red White Black

OK?

Troubleshooting the major components of the BC controller

Pressure sensor Pressure sensor troubleshooting flow

Start

HPS

Problem No abnormality

Temperature Sensor Thermistor troubleshooting flow

Temperature ˚C

Temperature sensor resistance graph

Resistance value Thermistor R o=15 k Ω Rt=15exp 273+t

LEV, Solenoid Valve Troubleshooting Flow

LEV

Output superheat BC controller

Subcool Solenoid Valve Troubleshooting Flow

Intermediate subcool BC controller liquid

Solenoid Valve

Normal Malfunction

SVM is turned on and off in accordance with operation mode

Disconnect the connector before measurement

SVM1

Service panel

BC Controller Disassembly Procedure

Control Box

Ler panel TH11 TH12 CN10 TH15, TH16 CN11

Thermistor Liquid and gas piping temperature detection

Be careful when removing heavy parts Procedure

100

LEV3 LEV1

101

LEV

Solenoid Valve Coil

102

103

CNRS2 CNRS3

Mechanical

CNAC2 TB1B

105

LEV3 SVM BC

106

SVM1 LEV3

LEV3 SVM SVA BC

107

LEV3 SVM

108

SVA SV3~8

Slev

109

2502 Drain pump

110

Once vacuum operation protection is

Indoor and outdoor units by oper

TB1A~NF~TB1B~CNTR1~F3~

111

T01~CNTR

VDC

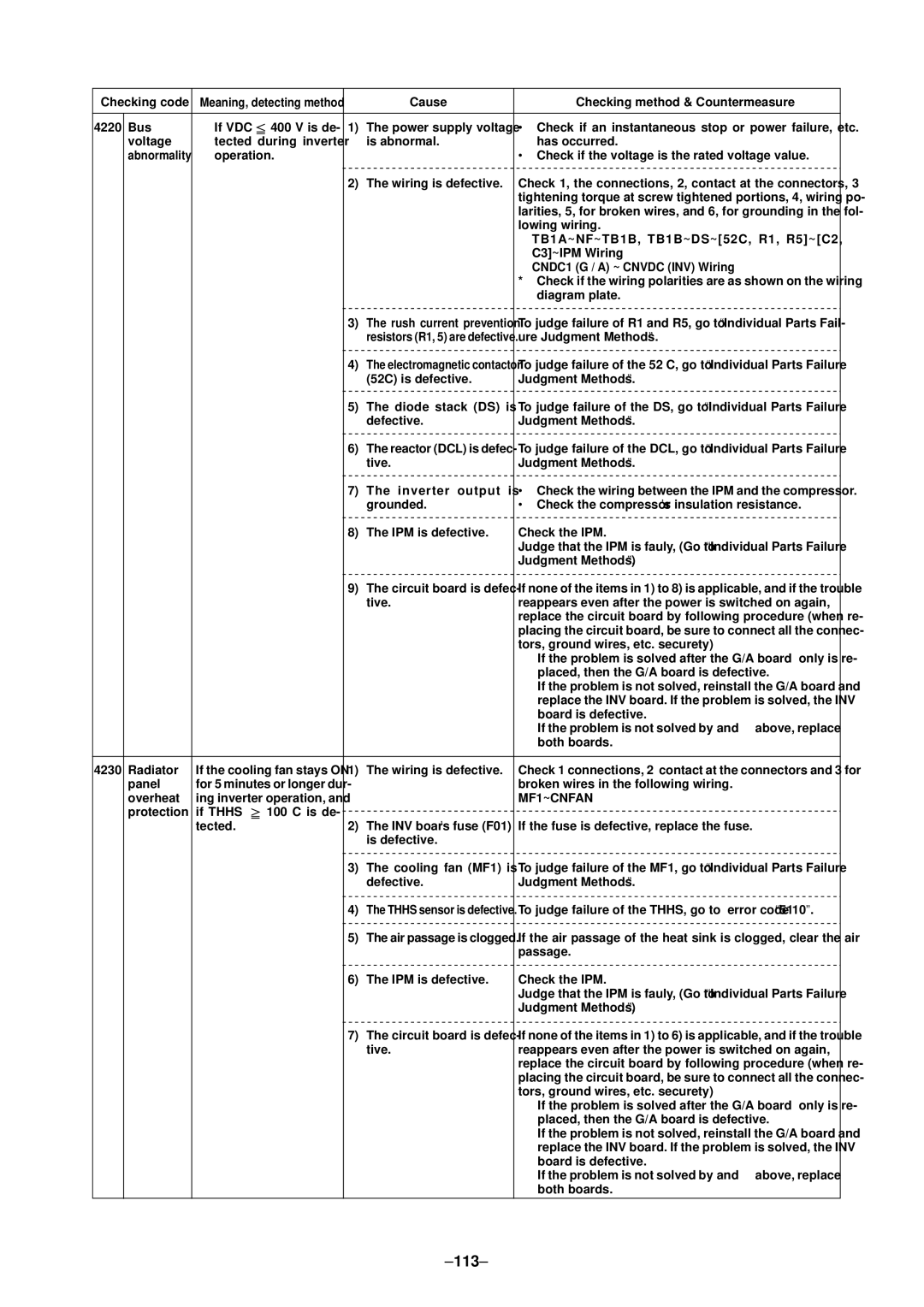

112

TB1A~NF~TB1B, TB1B~DS~52C

MF1~CNFAN

113

114

TH8

115

TH HS

Thhs TH5

CNDR2-CNDR1

116

IPM-MC1

117

Communication/system

Error

On, the wave shape is changed and the error is detected

118

→ Noise if existed, check the noise

Checking method and processing Error

119

Transmission circuit bus-busy er

120

Communication trouble between Faulty generating controller

More, and make them again

Shut down OC unit power source,

Remote No reply Faulty transmission wiring at IC unit side

Generating Display Detecting

122

123

124

125

System error

126

Comp

How to read LED for service monitor

LED Monitor Display

127

TH2 TH3 TH4 TH5 TH6 TH7

128

LD1 LD2 LD3 LD4 LD5 LD6 LD7 LD8

Comp COMP1

129

130

LD1 LD2 LD3 LD4 LD5 LD6 LD7 LD8

131

132

IC16SC

133

134

135

136

137

IC24SH

138

IC24SC

139

140

141

Check that all indoor units have been stopped

Location of leaks Outdoor unit Cooling mode

SC16 LED monitor switch

Stop all indoor units and the compressor

Location of leaks Outdoor unit when heating

144

LPS

145

Service Handbook PURY-P400, P500YMF-C