B – VERTICAL VENTS USING METAL VENT PIPE – COMMERCIAL AND RESIDENTIAL INSTALLATIONS

HSU compact unit heaters are listed as Category I appliances for vertical vent installations.

1.HSU unit heaters are to be used with NFPA- or

2.The vent connector shall be 3” (76mm) diameter on 50 units. In all cases, a flue transition piece (supplied) is required to fit over the outlet of the induced draft assembly on the appliance.

3.Keep the vent connector runs as short as possible with a minimum number of elbows. Refer to the (American) National Fuel Gas Code ANSI Z223.1 or (Canada) CSA B149.1 Natural Gas and Propane Installation Code for maximum vent and vent connector lengths. Horizontal run of the vent connector from the induced draft blower to the chimney/vent cannot exceed the values in table 2.

4.When the length of a single wall vent, including elbows, exceeds 5 feet (1.5m), the vent shall be insulated along its entire length with a minimum of 1/2” thick foil faced fiberglass

5.The unit may be vented vertically as a single appliance or as a common vent with other

6.Clearance to combustible material is 6” (152mm) for single wall vent material except where a listed clearance thimble is used. Clearance to combustible material for type

7.The vent connector shall be supported without any dips or sags. Vertical vents shall be supported in accordance with their listing and manufacturers’ instructions. All horizontal vent connector runs shall have a slope up to the vertical vent of at least 1/4” per foot (1mm per 50mm).

8.All vertical type

9.The vent must extend at least 3’ (1m) above the highest point where it passes through a roof of a building and at least 2’ (0.6m) higher than any part of a building within a horizontal distance of 10’ (3.05m) unless otherwise specified by the (American) National Fuel Gas Code, ANSI Z223.1 or (Canada)

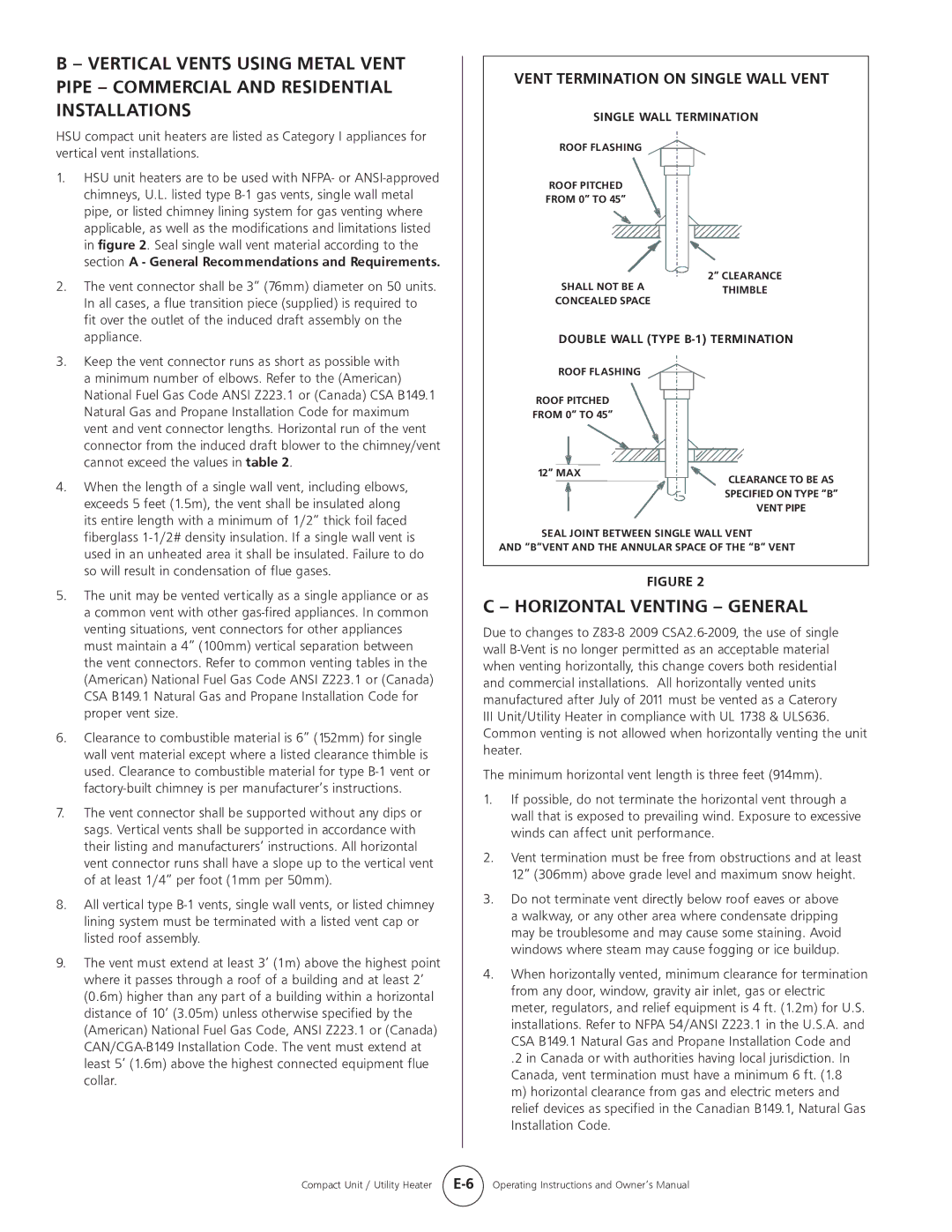

VENT TERMINATION ON SINGLE WALL VENT

SINGLE WALL TERMINATION

ROOF FLASHING

ROOF PITCHED

FROM 0” TO 45”

2” CLEARANCE

SHALL NOT BE ATHIMBLE CONCEALED SPACE

DOUBLE WALL (TYPE B-1) TERMINATION

ROOF FLASHING

ROOF PITCHED

FROM 0” TO 45”

12” MAX | CLEARANCE TO BE AS |

| |

| SPECIFIED ON TYPE “B” |

| VENT PIPE |

SEAL JOINT BETWEEN SINGLE WALL VENT

AND “B”VENT AND THE ANNULAR SPACE OF THE “B” VENT

FIGURE 2

C – HORIZONTAL VENTING – GENERAL

Due to changes to

IIIUnit/Utility Heater in compliance with UL 1738 & ULS636. Common venting is not allowed when horizontally venting the unit heater.

The minimum horizontal vent length is three feet (914mm).

1.If possible, do not terminate the horizontal vent through a wall that is exposed to prevailing wind. Exposure to excessive winds can affect unit performance.

2.Vent termination must be free from obstructions and at least 12” (306mm) above grade level and maximum snow height.

3.Do not terminate vent directly below roof eaves or above a walkway, or any other area where condensate dripping may be troublesome and may cause some staining. Avoid windows where steam may cause fogging or ice buildup.

4.When horizontally vented, minimum clearance for termination from any door, window, gravity air inlet, gas or electric meter, regulators, and relief equipment is 4 ft. (1.2m) for U.S. installations. Refer to NFPA 54/ANSI Z223.1 in the U.S.A. and CSA B149.1 Natural Gas and Propane Installation Code and

.2 in Canada or with authorities having local jurisdiction. In Canada, vent termination must have a minimum 6 ft. (1.8 m) horizontal clearance from gas and electric meters and relief devices as specified in the Canadian B149.1, Natural Gas Installation Code.

Compact Unit / Utility Heater | Operating Instructions and Owner’s Manual |