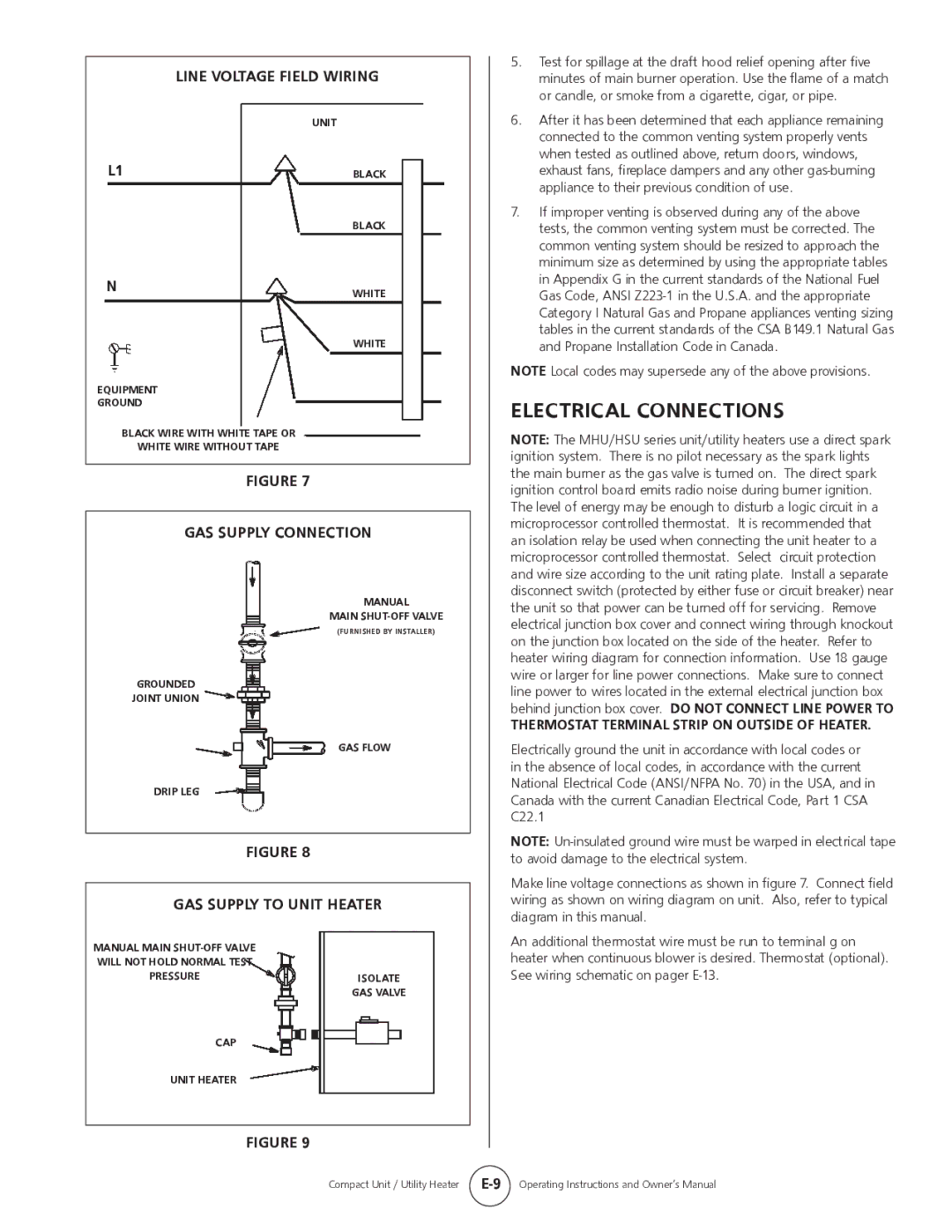

| LINE VOLTAGE FIELD WIRING |

| UNIT |

L1 | BLACK |

| BLACK |

N | WHITE |

| |

| WHITE |

EQUIPMENT

GROUND

BLACK WIRE WITH WHITE TAPE OR

WHITE WIRE WITHOUT TAPE

FIGURE 7

GAS SUPPLY CONNECTION

MANUAL

MAIN

(FURNISHED BY INSTALLER)

GROUNDED

JOINT UNION

GAS FLOW

DRIP LEG

FIGURE 8

GAS SUPPLY TO UNIT HEATER

MANUAL MAIN

WILL NOT HOLD NORMAL TEST

PRESSUREISOLATE GAS VALVE

CAP

UNIT HEATER

FIGURE 9

Compact Unit / Utility Heater

5.Test for spillage at the draft hood relief opening after five minutes of main burner operation. Use the flame of a match or candle, or smoke from a cigarette, cigar, or pipe.

6.After it has been determined that each appliance remaining connected to the common venting system properly vents when tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other

7.If improper venting is observed during any of the above tests, the common venting system must be corrected. The common venting system should be resized to approach the minimum size as determined by using the appropriate tables in Appendix G in the current standards of the National Fuel Gas Code, ANSI

NOTE Local codes may supersede any of the above provisions.

ELECTRICAL CONNECTIONS

NOTE:TheMHU/HSUseries seriesunit heatersunit/utilityuse aheatersdirect sparkuse ignitiondirect spark systemignition. Theresystemis. noTherepilotisnecessaryno pilot necessaryas the spasrkthelightssparkthelights mainthe mainburnerburneras theas gasthe gasv lvevalveis turnedis turnedon. Theon. dirThectdirectsparkspark

ignition control board emits radio noise during burner ignition. The level of energy may be enough to disturb a logic circuit in a microprocessor controlled thermostat. It is recommended that an isolation relay be used when connecting the unit heater to a microprocessor controlled thermostat. Select circuit protection and wire size according to the unit rating plate. Install a separate disconnect switch (protected by either fuse or circuit breaker) near the unit so that power can be turned off for servicing. Remove electrical junction box cover and connect wiring through knockout on the junction box located on the side of the heater. Refer to heater wiring diagram for connection information. Use 18 gauge wire or larger for line power connections. Make sure to connect line power to wires located in the external electrical junction box behind junction box cover. DO NOT CONNECT LINE POWER TO

THERMOSTAT TERMINAL STRIP ON OUTSIDE OF HEATER.

Electrically ground the unit in accordance with local codes or in the absence of local codes, in accordance with the current National Electrical Code (ANSI/NFPA No. 70) in the USA, and in Canada with the current Canadian Electrical Code, Part 1 CSA C22.1

NOTE:

Make line voltage connections as shown in figure 7. Connect field wiring as shown on wiring diagram on unit. Also, refer to typical diagram in this manual.

An additional thermostat wire must be run to terminal g on heater when continuous blower is desired. Thermostat (optional). See wiring schematic on pager