MAINTENANCE AND REPAIR INSTRUCTIONS

CHAIN MAINTENANCE

WARNING: Unless you have experience and

specialized training for dealing with kickback (see Safety Precautions), always use a

A

Always use a replacement saw chain designed as “low- kickback” or a saw chain which meets the

A standard saw chain (a chain which does not have the kickback reducing guard links) should only be used by an experienced professional chain saw operator.

What is a Low-Kickback Saw Chain?

A

By keeping the Chain Brake® and saw chain in good working condition and correctly serviced as recommended in this manual, you will be able to maintain the safety system of your chain saw over the life of the product.

Chain Tension

Check the chain tension frequently and adjust as often as necessary to keep the chain snug on the bar, but loose enough to be pulled around by hand.

Breaking in a New Saw Chain

A new chain and bar will need chain readjustment after as few as 5 cuts. This is normal during the

Over a period of time, however, the moving parts of the saw chain will become worn, resulting in what is called CHAIN STRETCH. This is normal. When it is no longer possible to obtain correct chain tension adjustment, a link will have to be removed to shorten the chain. See your Authorized Service Center to have this repair performed.

![]()

![]()

![]() WARNING: Never have more than 3 links

WARNING: Never have more than 3 links

removed from a loop of chain. This could cause damage to the sprocket.

Chain Lubrication

Always make sure the automatic oiler system is working properly. Keep the oil tank filled with Genuine Factory Parts Chain, Bar and Sprocket Oil.

Adequate lubrication of the bar and chain during cutting operations is essential to minimize friction with the guide bar.

Never starve the bar and chain of lubricating oil. Running the saw dry or with too little oil will decrease cutting efficiency, shorten saw chain life, cause rapid dulling of chain, and lead to excessive wear of bar from overheating. Too little oil is evidenced by smoke or bar discoloration.

Chain Sharpening

Chain sharpening requires special tools to ensure that cutters are sharpened at the correct angle and depth. For the inexperienced chain saw user, we recommend that the saw chain be professionally sharpened by the nearest Authorized Service Center. If you feel comfortable sharpening your own saw chain, special tools are available from your Authorized Service Center.

WARNING: Never remove, modify or make

inoperative any safety device furnished with your unit. The Chain Brake® / Hand Guard and

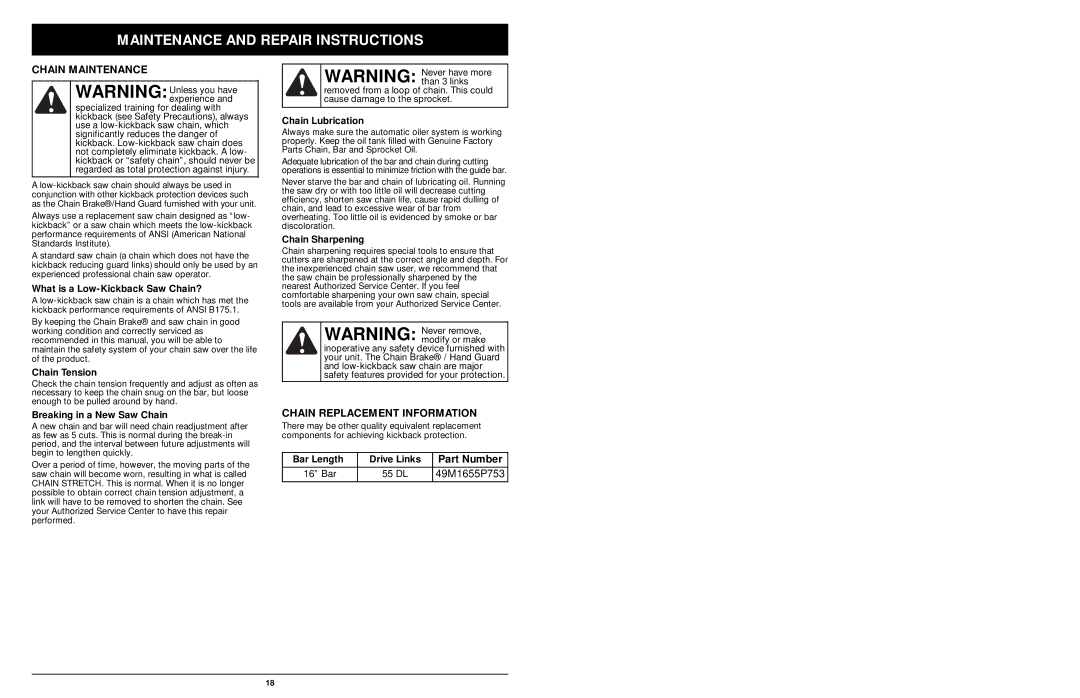

CHAIN REPLACEMENT INFORMATION

There may be other quality equivalent replacement components for achieving kickback protection.

Bar Length | Drive Links | Part Number |

|

|

|

16” Bar | 55 DL | 49M1655P753 |

|

|

|

18