MAINTENANCE AND REPAIR INSTRUCTIONS

GUIDE BAR MAINTENANCE

Frequent lubrication of the guide bar is required. Proper maintenance of the guide bar, as explained in this section, is essential to keep your saw in good working condition.

WARNING: Ensure that the power cord is

disconnected before performing any maintenance on your saw.

Sprocket Tip Lubrication

CAUTION: The sprocket tip on your new saw has

been

Lubrication of the sprocket tip is recommended after each saw use. Always thoroughly clean guide bar sprocket tip before lubrication.

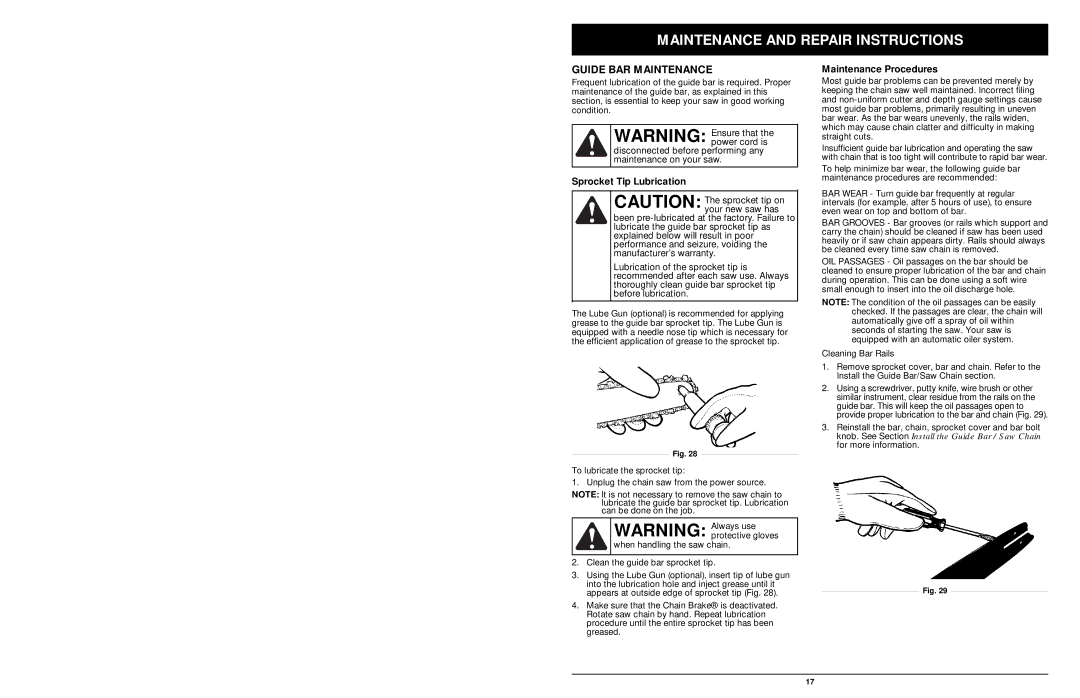

The Lube Gun (optional) is recommended for applying grease to the guide bar sprocket tip. The Lube Gun is equipped with a needle nose tip which is necessary for the efficient application of grease to the sprocket tip.

Fig. 28

To lubricate the sprocket tip:

1.Unplug the chain saw from the power source.

NOTE: It is not necessary to remove the saw chain to lubricate the guide bar sprocket tip. Lubrication can be done on the job.

![]()

![]()

![]() WARNING: Always use protective gloves

WARNING: Always use protective gloves

when handling the saw chain.

2.Clean the guide bar sprocket tip.

3.Using the Lube Gun (optional), insert tip of lube gun into the lubrication hole and inject grease until it appears at outside edge of sprocket tip (Fig. 28).

4.Make sure that the Chain Brake® is deactivated. Rotate saw chain by hand. Repeat lubrication procedure until the entire sprocket tip has been greased.

Maintenance Procedures

Most guide bar problems can be prevented merely by keeping the chain saw well maintained. Incorrect filing and

Insufficient guide bar lubrication and operating the saw with chain that is too tight will contribute to rapid bar wear.

To help minimize bar wear, the following guide bar maintenance procedures are recommended:

BAR WEAR - Turn guide bar frequently at regular intervals (for example, after 5 hours of use), to ensure even wear on top and bottom of bar.

BAR GROOVES - Bar grooves (or rails which support and carry the chain) should be cleaned if saw has been used heavily or if saw chain appears dirty. Rails should always be cleaned every time saw chain is removed.

OIL PASSAGES - Oil passages on the bar should be cleaned to ensure proper lubrication of the bar and chain during operation. This can be done using a soft wire small enough to insert into the oil discharge hole.

NOTE: The condition of the oil passages can be easily checked. If the passages are clear, the chain will automatically give off a spray of oil within seconds of starting the saw. Your saw is equipped with an automatic oiler system.

Cleaning Bar Rails

1.Remove sprocket cover, bar and chain. Refer to the Install the Guide Bar/Saw Chain section.

2.Using a screwdriver, putty knife, wire brush or other similar instrument, clear residue from the rails on the guide bar. This will keep the oil passages open to provide proper lubrication to the bar and chain (Fig. 29).

3.Reinstall the bar, chain, sprocket cover and bar bolt knob. See Section Install the Guide Bar / Saw Chain for more information.

Fig. 29

17