MAINTENANCE AND REPAIR INSTRUCTIONS

SAW CHAIN TENSION ADJUSTMENT

![]()

![]()

![]() WARNING: Always use protective gloves

WARNING: Always use protective gloves

when handling the saw chain.

Proper tension of saw chain is extremely important and must be checked before starting, as well as during any cutting operation.

Taking the time to make needed adjustments to the saw chain will result in improved cutting performance and prolonged chain life.

NOTE: A new chain and bar will need readjustment after as few as 5 cuts. This is normal during the break- in period, and the interval between future adjustments will lengthen quickly (Fig. 22).

CAUTION: If saw chain is TOO LOOSE or TOO

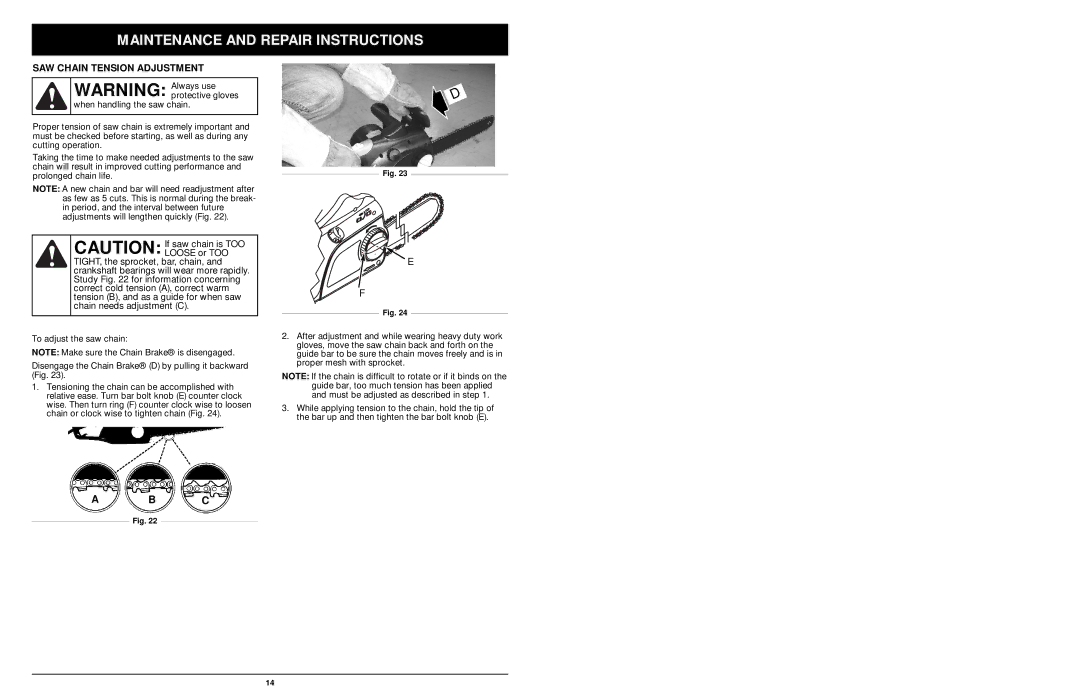

TIGHT, the sprocket, bar, chain, and crankshaft bearings will wear more rapidly. Study Fig. 22 for information concerning correct cold tension (A), correct warm tension (B), and as a guide for when saw chain needs adjustment (C).

To adjust the saw chain:

NOTE: Make sure the Chain Brake® is disengaged.

Disengage the Chain Brake® (D) by pulling it backward (Fig. 23).

1.Tensioning the chain can be accomplished with relative ease. Turn bar bolt knob (E) counter clock wise. Then turn ring (F) counter clock wise to loosen chain or clock wise to tighten chain (Fig. 24).

Fig. 23

E

F

Fig. 24

2.After adjustment and while wearing heavy duty work gloves, move the saw chain back and forth on the guide bar to be sure the chain moves freely and is in proper mesh with sprocket.

NOTE: If the chain is difficult to rotate or if it binds on the guide bar, too much tension has been applied and must be adjusted as described in step 1.

3.While applying tension to the chain, hold the tip of the bar up and then tighten the bar bolt knob (E).

A B C

Fig. 22

14