OPERATING INSTRUCTIONS

Fig. 11

LIMBING

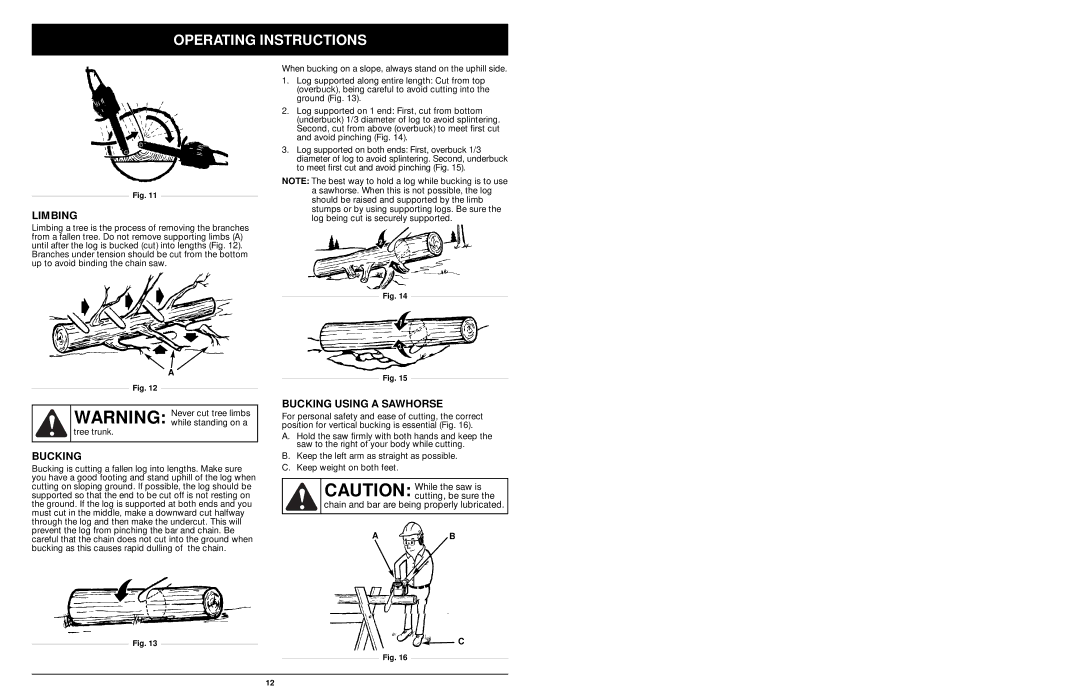

Limbing a tree is the process of removing the branches from a fallen tree. Do not remove supporting limbs (A) until after the log is bucked (cut) into lengths (Fig. 12). Branches under tension should be cut from the bottom up to avoid binding the chain saw.

A

Fig. 12

WARNING: Never cut tree limbs while standing on a

tree trunk.

BUCKING

Bucking is cutting a fallen log into lengths. Make sure you have a good footing and stand uphill of the log when cutting on sloping ground. If possible, the log should be supported so that the end to be cut off is not resting on the ground. If the log is supported at both ends and you must cut in the middle, make a downward cut halfway through the log and then make the undercut. This will prevent the log from pinching the bar and chain. Be careful that the chain does not cut into the ground when bucking as this causes rapid dulling of the chain.

When bucking on a slope, always stand on the uphill side.

1.Log supported along entire length: Cut from top (overbuck), being careful to avoid cutting into the ground (Fig. 13).

2.Log supported on 1 end: First, cut from bottom (underbuck) 1/3 diameter of log to avoid splintering. Second, cut from above (overbuck) to meet first cut and avoid pinching (Fig. 14).

3.Log supported on both ends: First, overbuck 1/3 diameter of log to avoid splintering. Second, underbuck to meet first cut and avoid pinching (Fig. 15).

NOTE: The best way to hold a log while bucking is to use a sawhorse. When this is not possible, the log should be raised and supported by the limb stumps or by using supporting logs. Be sure the log being cut is securely supported.

Fig. 14

Fig. 15

BUCKING USING A SAWHORSE

For personal safety and ease of cutting, the correct position for vertical bucking is essential (Fig. 16).

A.Hold the saw firmly with both hands and keep the saw to the right of your body while cutting.

B.Keep the left arm as straight as possible.

C.Keep weight on both feet.

![]()

![]()

![]() CAUTION: While the saw is cutting, be sure the

CAUTION: While the saw is cutting, be sure the

chain and bar are being properly lubricated.

AB

Fig. 13 |

| C |

|

Fig. 16

12