Table of Contents

BLW-400SSW —TRAILER SAFETY GUIDELINES

Table 4. Suspension Torque Requirements

Item | Torque |

|

|

3/8" |

|

|

|

7/16" |

|

|

|

1/2" | |

|

|

SHACKLE BOLT | SNUG FIT ONLY. PARTS MUST ROTATE FREELY. |

SPRING EYE BOLT | LOCKING NUTS OR COTTER PINS ARE PROVIDED TO |

| RETAIN |

|

|

SHOULDER TYPE | |

SHACKLE BOLT |

|

|

|

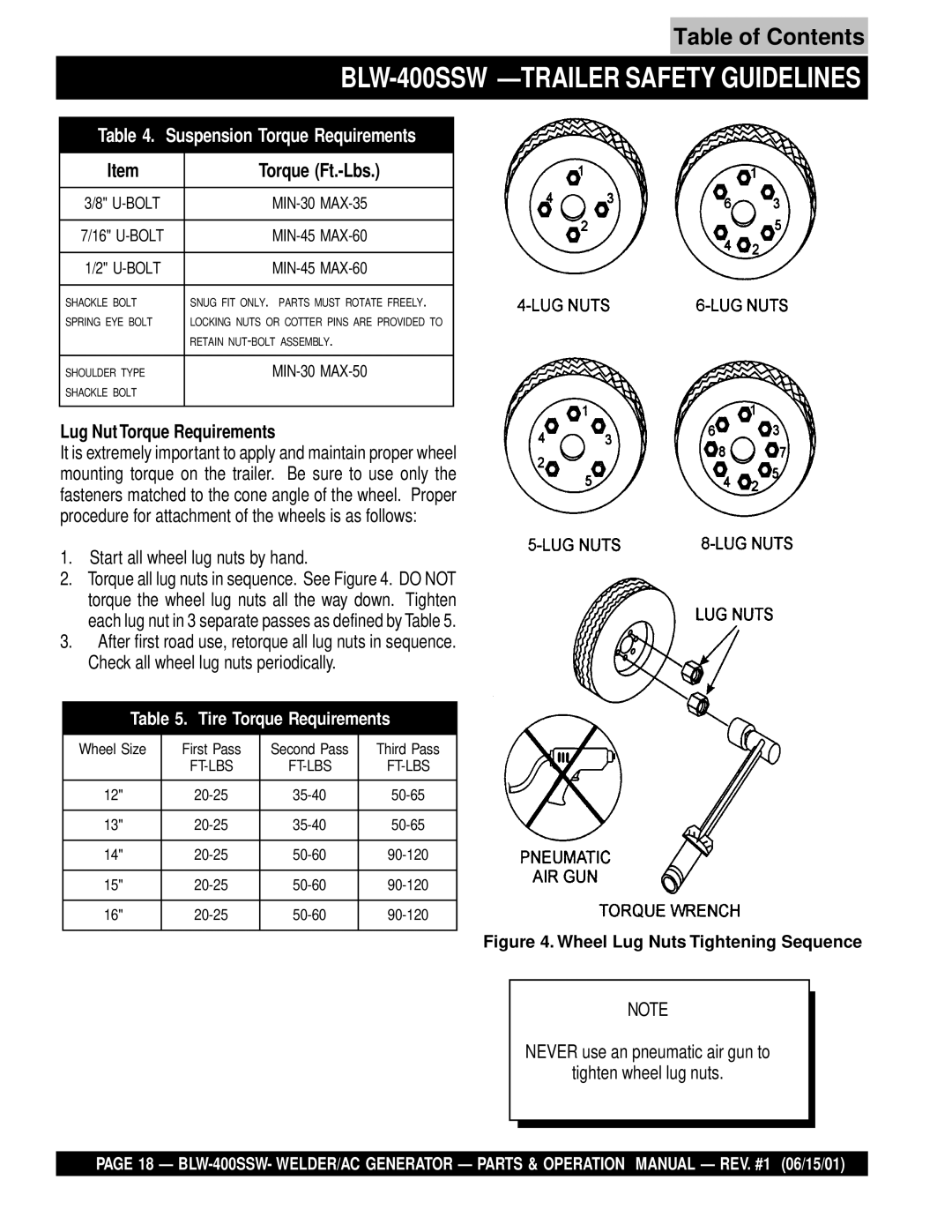

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel mounting torque on the trailer. Be sure to use only the fasteners matched to the cone angle of the wheel. Proper procedure for attachment of the wheels is as follows:

1.Start all wheel lug nuts by hand.

2.Torque all lug nuts in sequence. See Figure 4. DO NOT torque the wheel lug nuts all the way down. Tighten each lug nut in 3 separate passes as defined by Table 5.

3.After first road use, retorque all lug nuts in sequence. Check all wheel lug nuts periodically.

Table 5. Tire Torque Requirements

Wheel Size | First Pass | Second Pass | Third Pass |

| |||

|

|

|

|

12" | |||

|

|

|

|

13" | |||

|

|

|

|

14" | |||

|

|

|

|

15" | |||

|

|

|

|

16" | |||

|

|

|

|

Figure 4. Wheel Lug Nuts Tightening Sequence

NOTE

NEVER use an pneumatic air gun to

tighten wheel lug nuts.

PAGE 18 —