BGD40-P, BGD40-N specifications

Napoleon Fireplaces has long been a name synonymous with quality and innovation in the realm of hearth products. Among its impressive lineup, the BGD40-N and BGD40-P models stand out for their blend of performance, aesthetics, and technology, making them ideal choices for homeowners seeking both efficiency and style.The BGD40-N is a natural gas fireplace, designed with an emphasis on creating a warm and inviting atmosphere. One of its main features is the glass front that enhances its visual appeal while providing a clear view of the mesmerizing flames. This model is equipped with Napoleon's patented PHAZER log set, which mimics the appearance of real wood, further enriching the realistic ambiance.

In contrast, the BGD40-P is a propane version of the fireplace, offering similar design aesthetics and functionality tailored to propane users. Both models boast a high-efficiency rating, which means they maximize heat output while minimizing gas consumption. This efficiency not only reduces energy costs but also makes them environmentally friendly options for home heating.

One of the standout technologies featured in the BGD40 series is the advanced electronic ignition system. This system ensures that igniting the fireplace is a hassle-free experience, even during power outages when using the optional battery backup. Furthermore, the exclusive Heat Management System provides optimal airflow and distribution of heat, ensuring that living spaces are warmed effectively and consistently.

Safety features are paramount in both models, with a built-in safety shut-off system that enhances peace of mind for users. Additionally, the adjustable flame height allows homeowners to customize their experience, ranging from a gentle glow to a roaring fire.

The design flexibility of the BGD40-N and BGD40-P allows them to fit seamlessly into various home décors, complementing both modern and traditional interiors. With their sleek lines and customizable options, including different media choices, these fireplaces serve as focal points in any room.

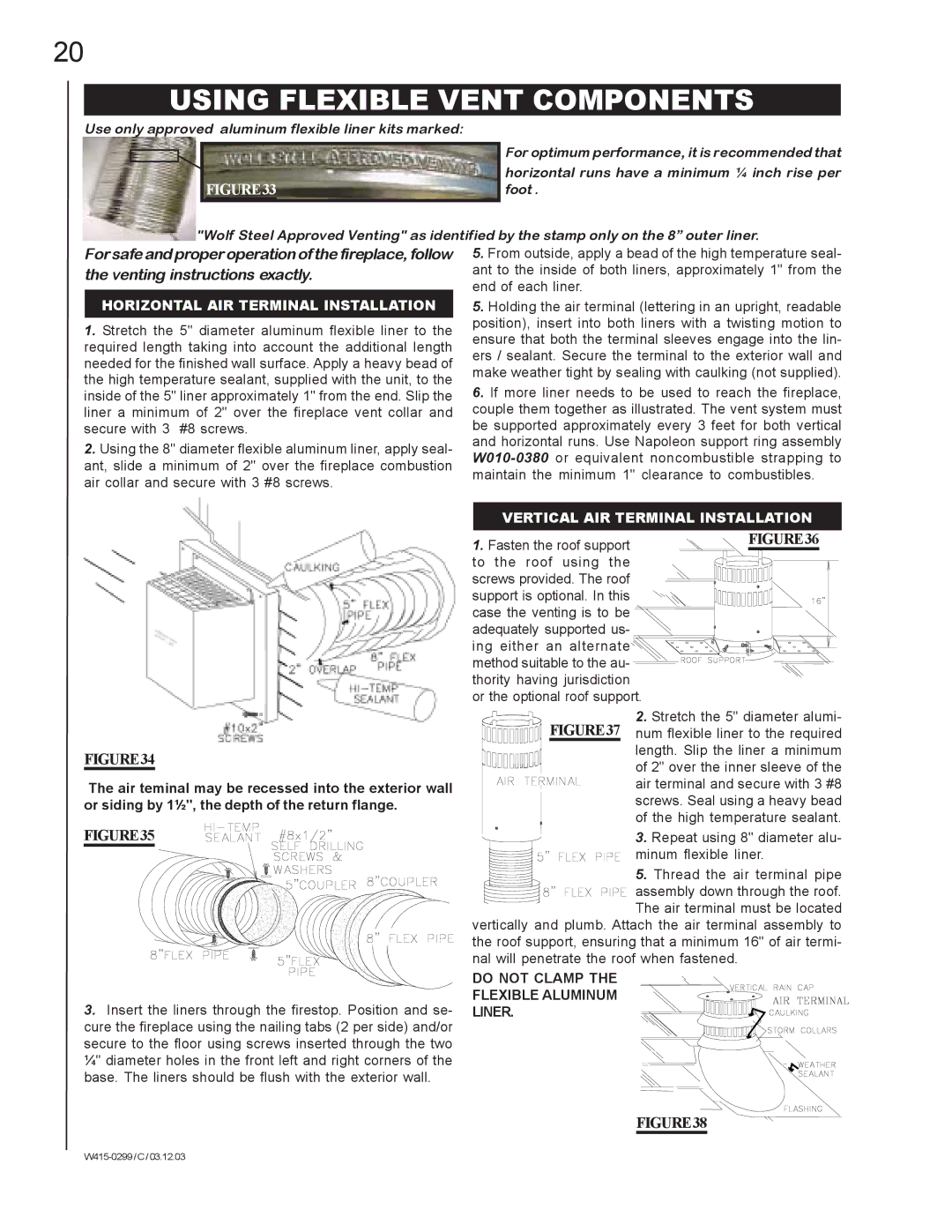

Installation is straightforward, with options available for both vented and direct vent configurations. This versatility means they can be installed in various locations, making them suited for new builds or retrofitting into existing structures.

In summary, Napoleon Fireplaces' BGD40-N and BGD40-P models deliver on aesthetics, efficiency, and innovative technology. With their realistic flame effects, user-friendly features, and commitment to safety, they are excellent choices for those seeking to enhance the comfort and ambiance of their homes.