343E specifications

The Nilfisk-ALTO 343E is a high-performance industrial vacuum cleaner designed to offer exceptional versatility and efficiency in various commercial and industrial cleaning applications. This model stands out for its robust build quality, advanced features, and user-friendly design, making it an ideal choice for businesses seeking effective solutions for dust and debris control.One of the main features of the Nilfisk-ALTO 343E is its powerful motor which delivers strong suction capabilities. With a maximum airflow of up to 400 m³/h, this vacuum is capable of handling a wide range of materials, including dust, chips, and liquids. The machine is equipped with a two-stage turbine that ensures efficient performance while maintaining low noise levels, making it suitable for use in environments where noise reduction is essential.

The 343E incorporates an advanced filtration system that significantly enhances its performance. It features a robust polyester filter that effectively captures fine particles, ensuring cleaner air is released back into the environment. Additionally, the filter is easy to clean, thereby extending its lifespan and reducing maintenance costs. The vacuum also provides an optional HEPA filter, which is vital for environments that require high levels of air purity, such as healthcare facilities or laboratories.

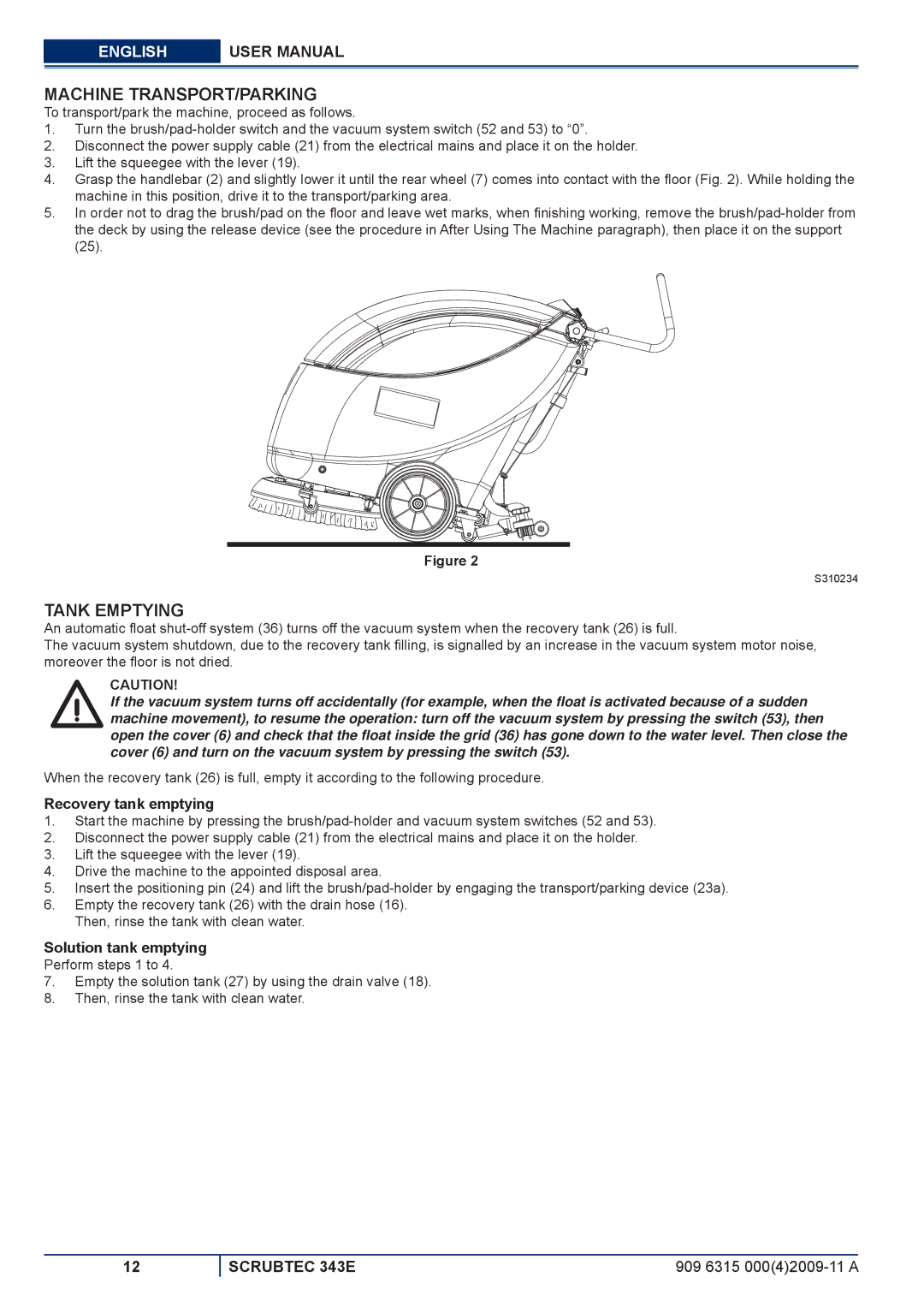

Another characteristic that sets the Nilfisk-ALTO 343E apart is its user-friendly design. The vacuum cleaner is built with ergonomic considerations, featuring an adjustable handle and wheels that make maneuvering around tight spaces effortless. The lightweight design further enhances mobility, allowing operators to transport the machine with ease.

The Nilfisk-ALTO 343E is also equipped with a large-capacity collection tank that can hold up to 35 liters, enabling extended cleaning sessions without frequent emptying. The tank features a quick-release design for hassle-free disposal of collected debris. Furthermore, the vacuum is designed for versatility, accommodating various tools and accessories to adapt to different cleaning tasks.

In summary, the Nilfisk-ALTO 343E combines powerful suction, advanced filtration, user-centric design, and versatility, making it an indispensable tool in sectors such as manufacturing, construction, and maintenance. Its combination of efficiency and ease of use ensures that it meets the demanding needs of modern industrial cleaning requirements.