EY7270 EY7271

Model No EY7270/EY7271

EY7270

EY7271

EY7270EU.indb 2006/05/25

Luce LED

Attaching or Removing Socket EY7271

II. Assembly

Rules

Attaching or Removing Bit EY7270

III. Operation

Attaching or Removing Battery Pack

Select the Impact Mode

Switch and Forward/Reverse Lever Operation

LED Light

Forward Rotation Switch Operation

Reverse Rotation Switch Operation

How to Use the Belt Hook

To Change the Belt Hook Location Side

Appropriate Use of Battery Pack

To Set the Belt Hook Angle Position

During charging, the charging lamp will be lit

Charging

For Business Users in the European Union

IV. Maintenance

Torque

Lamp Indications

Tightening time

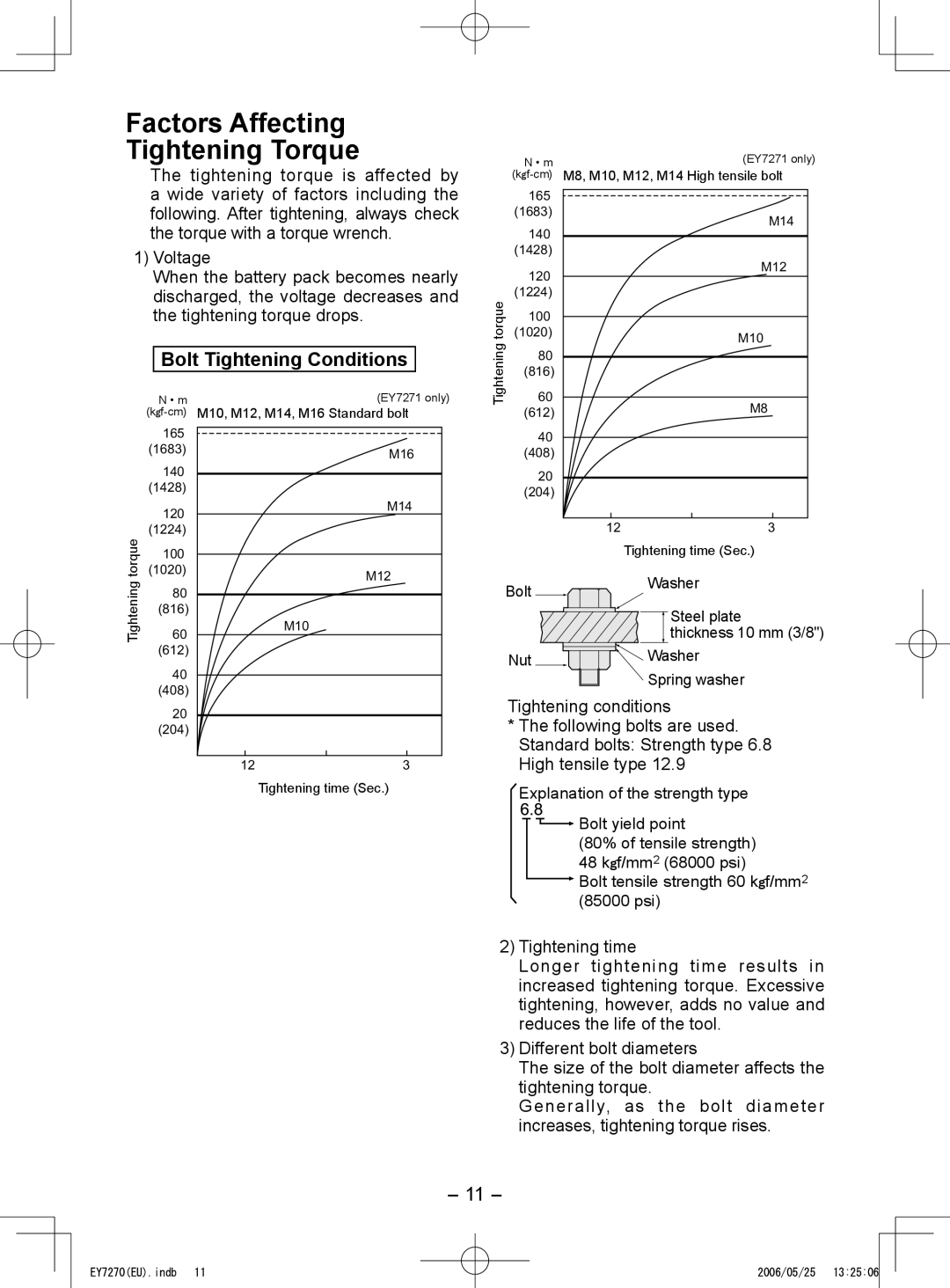

Factors Affecting Tightening Torque

Bolt Tightening Conditions

Tightening conditions

Main Unit

VI. Accessories

VII. Specifications

Maximum Recommended Capacities

Battery Charger

Battery Pack

Fuse Cover This apparatus was produced to BS800

Only for U. K

Information

Memo

Anbringen oder Abnehmen einer Stecknuss EY7271

Weitere Wichtige

II. Baugruppe

Anbringen oder Abnehmen des Bits EY7270

Vorsicht

III. Betrieb

Anbringen oder Abnehmen des Akkus

Wahl des Schlagmodus

Umschalten und Betätigung des Vorwärts-/Rückwärtshebels

Vorwätsdrehung Schal terbetätigung

LED-Leuchte

Rückwärtsdrehung-Schal terbetätigung

Warnung

Verwenden des Riemen hakens

Die Riemenhaken-Winkel position einstellen

Ändern der Befestigungsseite des Riemenhakens

Lebensdauer des Akkus

Korrekter Gebrauch des Akkus

Laden

Ni-MH-Akku EY9201

Anzeigelampen

Für Geschäftskunden in der Europäischen Union

IV. Wartung

ANZIEHDREHMO Ment

Faktoren, die dasAnziehdreh moment beeinflussen

Maximal Zulässige Kapazitäten

VI. Zubehör

AKKU-LADEGERÄT

VII. Technische Daten

Hauptgerät

Akku

Remarque

II. Montage

Fixation ou retrait d’une mèche EY7270

Fixation ou retrait de la douille EY7271

Fixation ou retrait de la batterie autonome

Sélectionnez le mode d’impact

Tableau de référence des travaux recommandés

Verrouillage de Commutateur

Lumière DEL

Utilisation du commutateur de rotation en sens inverse

Utilisation du commutateur pour une rotation en sens normal

Avertissement

Comment utiliser le crochet de ceinture

Pour régler l’angle de posi- tion du crochet de ceinture

Longévité des batteries autonomes

Utilisation correcte de la batterie autonome

Recharge

Batterie Ni-MH EY9201

Débranchez le chargeur lorsque vous ne l’utilisez pas

Indication DU Voyant

Utilisateurs professionnels de l’Union Européenne

IV. Entretien

Couple DE SER Rage

Facteurs affectant le couple de serrage

Temps de serrage

Unite Principale

VI. Accessoires

Capacites Maximum Recommandees

VII. Caracteristiques Techniques

Chargeur DE Batterie

Nota

II. Montaggio

Applicazione e rimozione del bit EY7270

Applicazione o rimozione della bussola EY7271

Tabella indicazioni consigliate

III. Funzionamento

Selezionare la modalità di impatto

Applicazione o rimozione del pacco batteria

Luce LED

Uso della leva di avanza mento/inversione

Uso dell’interruttore di rotazione in avanti

Uso dell’interruttore di rotazione all’indietro

Avvertimento

Come utilizzare il gancio da cintura

Modifica del lato del gan- cio da cintura

Regolazione dell’angola zione del gancio da cintura

Durata del pacco batteria

Per un uso corretto del pacco batteria

Ricarica

Pacco batteria Ni-MH EY9201

Segnali Spie

Condizioni di serraggio dei bulloni

IV. Manutenzione

Coppia DI SER Raggio

Per gli utenti aziendali nellUnio ne Europea

Modello EY7270/7271 Avvita Vite da legno

VI. Accessori

Utilizzare solo i bit adatti per la dimensione del mandrino

Capacità Massime Consigliate

Caricabatteria

VII. Specifiche Tecniche

Apparecchio Principale

Pacco Batteria

Opmerking

Voorschriften

Bevestigen of verwijderen van de bit EY7270

Bevestigen of verwijderen van de dop EY7271

Tabel met aanbevolen werkrichtlijnen

III. Bediening

Bevestigen en verwijderen van de accu

Kies de slagfunctie

Bediening van de schake laar voor linksomdraaien

LED-lampje

Bediening van de schake laar voor rechtsomdraaien

Juist gebruik van de accu

Gebruik van de riemclip

Instellen van de stand van de riemclip

Verplaatsen van de riem- clip

Attentie

Opladen

Levensduur van de accu

Recyclen van de accu

Voor zakelijke gebruikers in de Europese Unie

Lampindicaties

Zijn bedoeld als referentie

IV. Onderhoud

Aanhaalmoment

Aanhaalmomenten van bouten

Boutbevestiging EY7270

Aanbevolen Maximale Capaciteiten

EY7270/7271 Schroeven Houtschroef

Tek-schroef

Acculader

VII. Technische Gegevens

Gereedschap

Accu

Instalación o desmontaje del cubo EY7271

DAD Adicionales

II. Montaje

Colocación o extracción de la broca EY7270

Cuadro de guías de trabajo reco- mendadas

III. Funcionamiento

Colocación y extracción de la batería

Selección del modo de impacto

Funcionamiento del inter ruptor de rotación de avance

Luz indicadora

Funcionamiento del inter ruptor de rotación inversa

¡ADVERTENCIA

Cómo utilizar el gancho del cinturón

Para cambiar el lugar de ubicación del gancho de cinturón

Vida útil de la batería

Carga

Uso apropiado de la batería

Batería Ni-MH EY9201

Deben mezclarse con la basura doméstica general

Indicación DE LA Lámpara

Para empresas de la Unión Europea

PAR DE Apriete

IV. Mantenimientoe

Factores que afectan al par de apriete

Máximas Capacidades Recomendadas

VI. Accesorios

Cargador DE Batería

VII. Especificaciones

Unidad Principal

Batería

Montering og afmontering af borholder EY7271

Ekstra SIKKER Hedsregler

II. Montering

Montering eller afmonter ing af bit EY7270

Anvendelse af grebet til forlæns/baglæns retning

III. Betjening

Isætning og udtagning af batteripakningen

Valg af slagfunktion

Hvordan bæltekrogen bruges

Forlæns rotation betjen ing af omskifter

Baglæns rotation betjen ing af omskifter

LED-lys

Ni-MH batteripakning EY9201

Ændring af bæltekrogens placering

Korrekt brug af batteripak ningen

Indstilling af bæltekrogens vinkelposition

Under opladningen vil opladelampen lyse

Opladning

Genbrug af batterier

OBS

Professionelle brugere i EU

IV. VEDLIGEHOLD Else

Stramnings Moment

Lampeindikeringer

Stramningsbetingelser

Faktorer, som påvirker stram ningsmomentet

Forhold ved stramning af bolte

Spænding

Hovedenhed

VI. Tilbehør

VII. Tekniske Specifikationer

MAKS. Tilladte Kapaciteter

Vægt 78 kg 15,6

Batteripakning

Batterioplader

Mærkedata

Observera

Regler

Isättning/urtagning av bits EY7270

Montering/demontering av hylsa EY7271

Användning av riktningsom kopplaren och avtryckaren

III. Drift

Montering/demontering av batteri

Val av slagläge

Hur bälteskroken används

Drift med rotation framåt

Drift med rotation bakåt

LED-ljus

Ni-MH-batteri EY9201

Inställning av bälteskro- kens vinkel

Montering av bälteskro- ken på motsatt sida

Korrekt hantering av batteri

Anmärkning

Laddning

Batteriåtervinning

För företagsanvändare inom den Europeiska gemenskapen

IV. Skötsel

ÅTDRAGNINGSMO Ment

Lampindikationer

Åtdragningstid

Faktorer som påverkar åt- dragningsmomentet

Bultåtdragningsförhållanden

Åtdragningsförhållanden

Slagskruvdragare

VI. Tillbehör

VII. Specifikationer

Rekommenderade SKRUV- OCH Bultstorlekar

Batteriladdare

Batteri

Merk

Ekstra SIKKER Hetsregler

Montere eller demontere en bit EY7270

Montering eller demonte ring Hylse EY7271

Tabell med anbefalte retningslin- jer for arbeid

Montere eller demontere batteripakken

Valg av slagstyrke

Bruk av forover-/bakoverbry ter

Hvordan bruke beltekroken

Bryterbetjening ved forover rotasjon

Bryterbetjening ved bako ver rotasjon

LED lys

Riktig bruk av Batteripakke

Sette beltekroken i en vink let stilling

Endre side for feste av belte kroken

Lading

Lampeindikatorer

IV. Vedlikehold

Dreiemomentfor Tilstramming

Tilstrammingstid

Faktorer som påvirker dreie momentet for tilstramming

Tilstrammingsforhold for bolter

Tilstrammingsforhold

Hovedenhet

VI. Tilleggsutstyr

VII. Spesifikasjoner

Største Anbefalte Kapasiteter

Vekt

Batteripakke

Batterilader

Merkedata

Huomautus

II. Kokoaminen

Terän kiinnittäminen tai irrottaminen EY7270

Hylsyn kiinnittäminen tai irrottaminen EY7271

Toimintakytkimen ja eteen päin/taaksepäin vivun toiminta

III. Toiminta

Akun kiinnittäminen tai irrottaminen

Iskumuodon valinta

Eteenpäin tapahtuvan pyö rinnän kytkimen käyttö

LED-valo

Vyölenkin käyttö

Taaksepäin tapahtuvan pyörinnän kytkimen käyttö

Akun oikea käyttö

Vyölenkin kulman aset- taminen

Vyölenkin käyttöpuolen muuttaminen

Älä missään tapauksessa työnnä sormiasi latauspesään

Lataus

Lampun Merkinnät

IV. Huolto

Kiristysmomentti

Kiristysmomenttiin vaikut tavia tekijöitä

Erilaiset pultin halkaisijat

Pultin kiristyksen olosuhteet

Kiristysolosuhteet

Kiristysaika

Päälaite

VI. Varusteet

VII. Tekniset Tiedot

Suurimmat Suositellut Kapasiteetit

Latausaika

Akkulaturi

Внимание

II. Сборка

Закрепление или снятие насадки EY7270

Примечание

Закрепление или снятие патрона EY7271

III. Функционирование

Закрепление или снятие батарейного блока

Выбор режима удара

Таблица рекомендуемых указаний по работе

Н к ц и о н и р о в а н и е переключателя вращения вперед

Светодиодная подсветка

Функционирование перек лючателя вращения назад

101

Чтобы установить угол поворота поясного крюка

Какпользоватьсяпоясным крюком

Осторожно

Утилизация батареи

Зарядка

Чтобы изменить сторону размещения поясного крюка

Срок службы батарейного блока

Во время зарядки будет гореть лампочка зарядки

103

Плотно вставьте батарейный блок в зарядное устройство

Условия затяжки болта

IV. Обслуживание

Факторы, влияющие на крутящий момент затяжки

Световые Индикаторы

Время затяжки

VI. Принадлежности

105

Батарейный Блок

VII. Технические Характеристики

Максимальные Рекомендуемые Нагрузки

Основное Устройство

Вашем регионе. Пожалуйста, обратитесь к каталогу 107

Зарядное Устройство

Увага

II. Збірка

Закріплення або знімання насадки EY7270

Примітка

Закріплення або знімання патрону EY7271

III. Функціонування

Вибір режиму удару

Закріплення або знімання батарейного блоку

Таблиця вказівок по роботі, що рекомендуються

Світлодіодне підсвічування

Функціонування перемикача обертання вперед

Функціонування перемикача обертання назад

111

Як користуватися поясним крюком

Щоб встановити кут повороту поясного крюка

Обережно

Термін служби батарейного блоку

Для належного викорис тання батарейного блока

Щоб змінити сторону розміщення поясного крюка

К е л ь металогідридний батарейний блок EY9201

113

114

Фактори, що впливають на крутильний момент затяжки

Світлові Індикатори

Умови затяжки болта

115

VI. Приладдя

Батарейний Блок

VII. Технічні Характеристики

Максимальні НАВАНТАЖЕННЯ, ЩО Рекомендуються

Основний Пристрій

117

Зарядний Пристрій

118

119

Osaka, Japan

![]() Bolt yield point

Bolt yield point![]() Bolt tensile strength 60 kgf/mm2 (85000 psi)

Bolt tensile strength 60 kgf/mm2 (85000 psi)