5

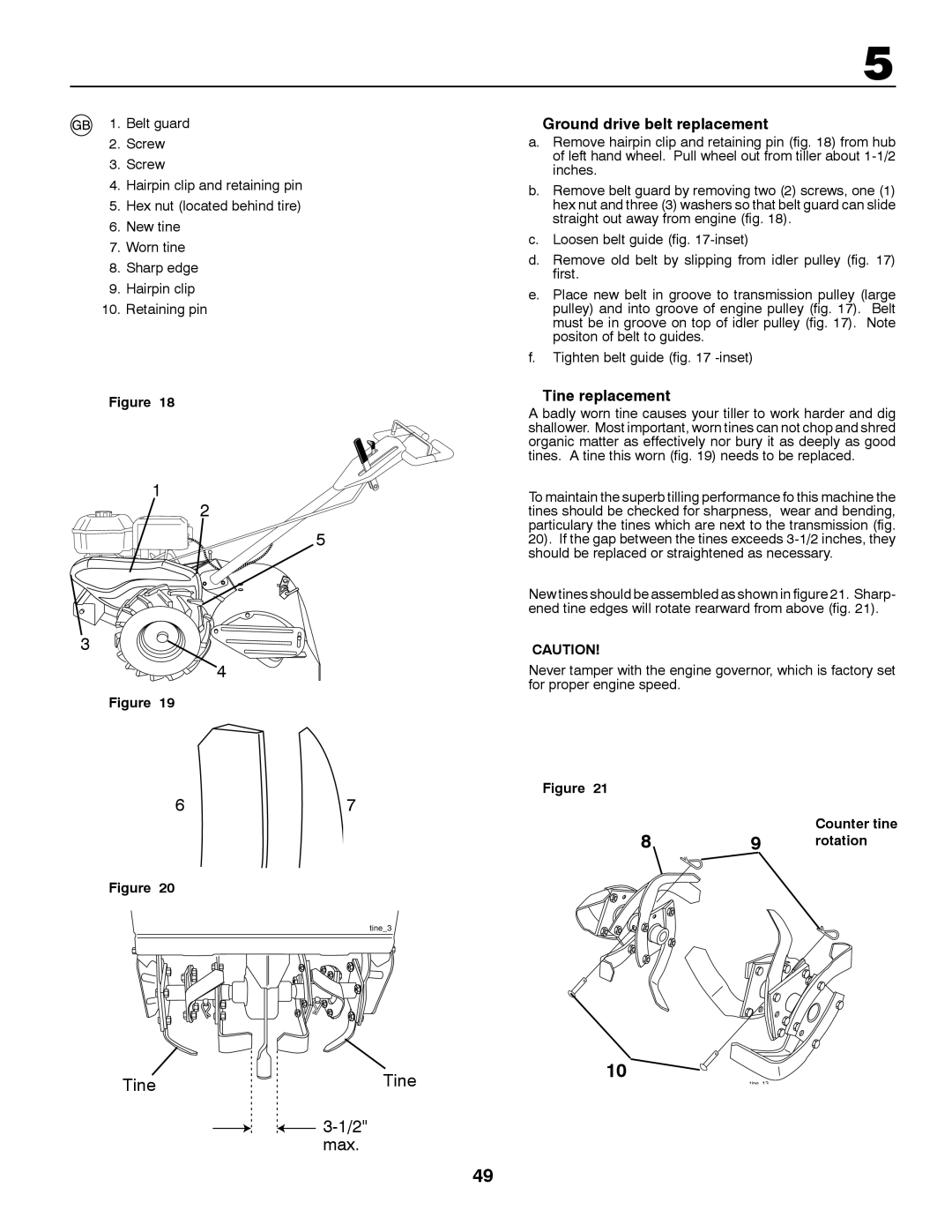

1. Belt guard

2.Screw

3.Screw

4.Hairpin clip and retaining pin

5.Hex nut (located behind tire)

6.New tine

7.Worn tine

8.Sharp edge

9.Hairpin clip

10.Retaining pin

Figure 18

1

2  5

5

3

4

Figure 19

67

Figure 20

tine_3

Tine | Tine |

3-1/2" max.

Ground drive belt replacement

a.Remove hairpin clip and retaining pin (fig. 18) from hub of left hand wheel. Pull wheel out from tiller about

b.Remove belt guard by removing two (2) screws, one (1) hex nut and three (3) washers so that belt guard can slide straight out away from engine (fig. 18).

c.Loosen belt guide (fig.

d.Remove old belt by slipping from idler pulley (fig. 17) first.

e.Place new belt in groove to transmission pulley (large pulley) and into groove of engine pulley (fig. 17). Belt must be in groove on top of idler pulley (fig. 17). Note positon of belt to guides.

f.Tighten belt guide (fig. 17

Tine replacement

A badly worn tine causes your tiller to work harder and dig shallower. Most important, worn tines can not chop and shred organic matter as effectively nor bury it as deeply as good tines. A tine this worn (fig. 19) needs to be replaced.

To maintain the superb tilling performance fo this machine the tines should be checked for sharpness, wear and bending, particulary the tines which are next to the transmission (fig. 20). If the gap between the tines exceeds

New tines should be assembled as shown in figure 21. Sharp- ened tine edges will rotate rearward from above (fig. 21).

CAUTION!

Never tamper with the engine governor, which is factory set for proper engine speed.

Figure 21

8 | 9 | Counter tine |

rotation |

10

tine 13

49