Section IV. Operation

SAFETY CONTROLS, (cont’d.)

Flame Current

Check Point

HIGH LIMITS

A “High Limit”, is a safety device that opens the electrical circuit and shuts off the heater based on a water temperature set point within the “High Limit Device”. The MiniMax NT LN series of heaters contains two (2) high limit devices which are located on the main inlet / outlet header, one sensing the inlet water temperature and one sensing the outlet water temperature.

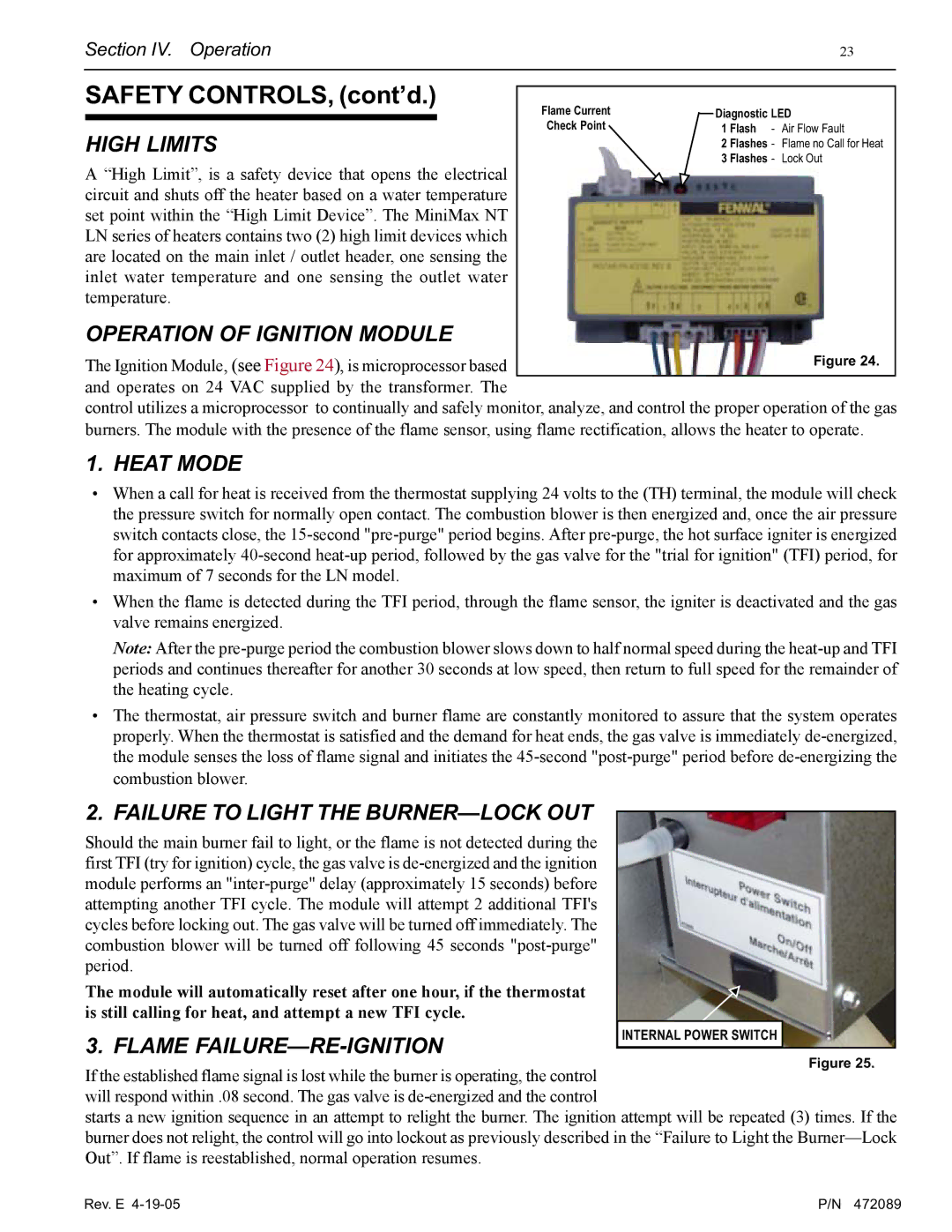

OPERATION OF IGNITION MODULE

The Ignition Module, (see Figure 24), is microprocessor based and operates on 24 VAC supplied by the transformer. The

control utilizes a microprocessor to continually and safely monitor, analyze, and control the proper operation of the gas burners. The module with the presence of the flame sensor, using flame rectification, allows the heater to operate.

1. HEAT MODE

•When a call for heat is received from the thermostat supplying 24 volts to the (TH) terminal, the module will check the pressure switch for normally open contact. The combustion blower is then energized and, once the air pressure switch contacts close, the

•When the flame is detected during the TFI period, through the flame sensor, the igniter is deactivated and the gas valve remains energized.

Note: After the

•The thermostat, air pressure switch and burner flame are constantly monitored to assure that the system operates properly. When the thermostat is satisfied and the demand for heat ends, the gas valve is immediately

2. FAILURE TO LIGHT THE BURNER—LOCK OUT

Should the main burner fail to light, or the flame is not detected during the first TFI (try for ignition) cycle, the gas valve is

The module will automatically reset after one hour, if the thermostat is still calling for heat, and attempt a new TFI cycle.

3. FLAME FAILURE—RE-IGNITION

INTERNAL POWER SWITCH

If the established flame signal is lost while the burner is operating, the control will respond within .08 second. The gas valve is

starts a new ignition sequence in an attempt to relight the burner. The ignition attempt will be repeated (3) times. If the burner does not relight, the control will go into lockout as previously described in the “Failure to Light the

Rev. E | P/N 472089 |