Section III. Installation | 8 |

|

|

|

| TO | PUMP |

|

| POOL | |

POOL |

| FILTER | |

MANUAL |

| ||

HEATER |

|

| |

|

| ||

|

|

| |

| CHECK | GATE |

|

| VALVE |

| |

| VALVE |

|

|

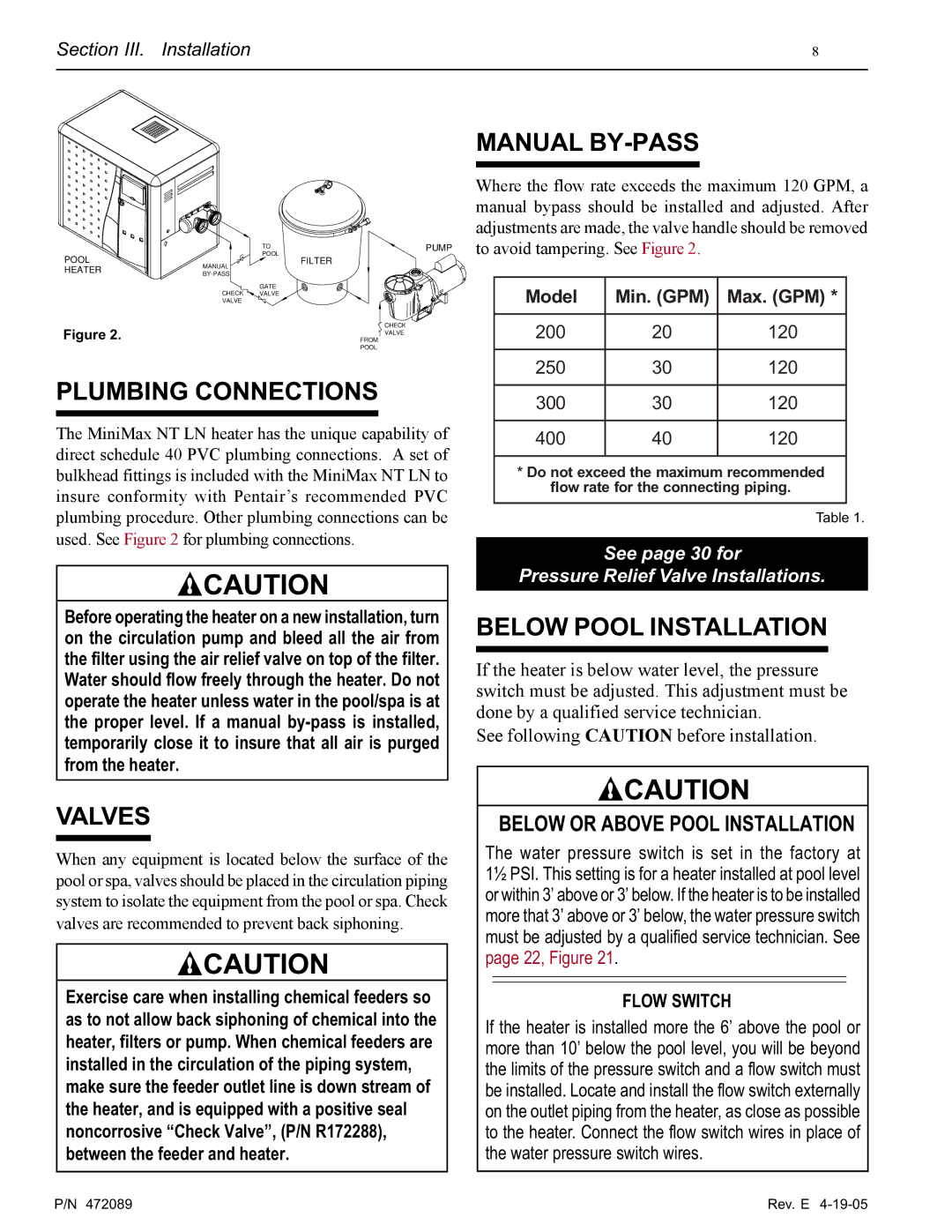

Figure 2. |

|

| CHECK |

|

| FROM | |

|

|

| VALVE |

|

|

| POOL |

PLUMBING CONNECTIONS

The MiniMax NT LN heater has the unique capability of direct schedule 40 PVC plumbing connections. A set of bulkhead fittings is included with the MiniMax NT LN to insure conformity with Pentair’s recommended PVC plumbing procedure. Other plumbing connections can be used. See Figure 2 for plumbing connections.

![]() CAUTION

CAUTION

Before operating the heater on a new installation, turn on the circulation pump and bleed all the air from the filter using the air relief valve on top of the filter. Water should flow freely through the heater. Do not operate the heater unless water in the pool/spa is at the proper level. If a manual

VALVES

When any equipment is located below the surface of the pool or spa, valves should be placed in the circulation piping system to isolate the equipment from the pool or spa. Check valves are recommended to prevent back siphoning.

![]() CAUTION

CAUTION

Exercise care when installing chemical feeders so as to not allow back siphoning of chemical into the heater, filters or pump. When chemical feeders are installed in the circulation of the piping system, make sure the feeder outlet line is down stream of the heater, and is equipped with a positive seal noncorrosive “Check Valve”, (P/N R172288), between the feeder and heater.

MANUAL BY-PASS

Where the flow rate exceeds the maximum 120 GPM, a manual bypass should be installed and adjusted. After adjustments are made, the valve handle should be removed to avoid tampering. See Figure 2.

Model | Min. (GPM) | Max. (GPM) * |

|

|

|

|

|

200 | 20 | 120 |

|

|

|

|

|

250 | 30 | 120 |

|

|

|

|

|

300 | 30 | 120 |

|

|

|

|

|

400 | 40 | 120 |

|

|

|

|

|

* Do not exceed the maximum recommended |

| ||

flow rate for the connecting piping. |

| ||

|

|

|

|

|

| Table 1. | |

See page 30 for

Pressure Relief Valve Installations.

BELOW POOL INSTALLATION

If the heater is below water level, the pressure switch must be adjusted. This adjustment must be done by a qualified service technician.

See following CAUTION before installation.

![]() CAUTION

CAUTION

BELOW OR ABOVE POOL INSTALLATION

The water pressure switch is set in the factory at 1½ PSI. This setting is for a heater installed at pool level or within 3’ above or 3’ below. If the heater is to be installed more that 3’ above or 3’ below, the water pressure switch must be adjusted by a qualified service technician. See page 22, Figure 21.

FLOW SWITCH

If the heater is installed more the 6’ above the pool or more than 10’ below the pool level, you will be beyond the limits of the pressure switch and a flow switch must be installed. Locate and install the flow switch externally on the outlet piping from the heater, as close as possible to the heater. Connect the flow switch wires in place of the water pressure switch wires.

P/N 472089 | Rev. E |