Fig. DD

2

1![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 3

3

6.If the blade and riving knife are not correctly aligned, adjustment is needed.

7.Loosen the two larger lock screws (4).

8.Locate the four samll set screws (5) adjacent to the riving knife lock knob(6). Adjust the small set screws to move the riving knife according to the position noted in step 4. Lay the combination square on the opposite side of the blade and repeat adjustment as needed.

9.Lightly tighten the two larger lock screws.

10.Place a square flat against the riving knife to verify riving knife is vertical and in line with the blade.

11.If needed, use the set screws to bring the riving knife vertical with the square.

12.Repeat steps 7 and 8 to verify position of riving knife.

13.Fully tighten the two larger lock screws.

Fig. EE

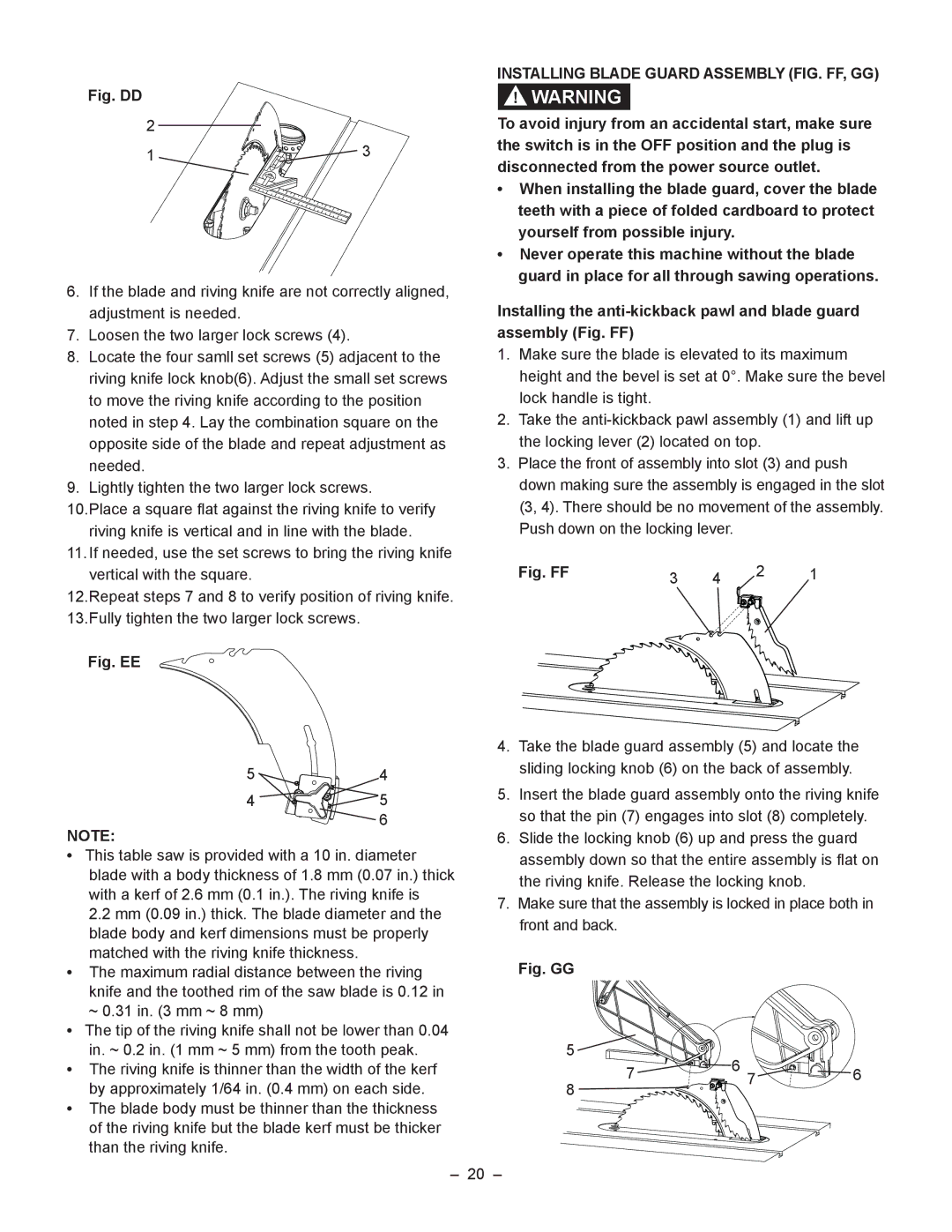

INSTALLING BLADE GUARD ASSEMBLY (FIG. FF, GG)

!WARNING

To avoid injury from an accidental start, make sure the switch is in the OFF position and the plug is disconnected from the power source outlet.

•When installing the blade guard, cover the blade teeth with a piece of folded cardboard to protect yourself from possible injury.

•Never operate this machine without the blade guard in place for all through sawing operations.

Installing the

1.Make sure the blade is elevated to its maximum height and the bevel is set at 0°. Make sure the bevel lock handle is tight.

2.Take the

3.Place the front of assembly into slot (3) and push down making sure the assembly is engaged in the slot (3, 4). There should be no movement of the assembly. Push down on the locking lever.

Fig. FF | 3 | 4 | 2 | 1 |

5 | 4 |

4 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 5

5 ![]()

![]()

![]()

![]()

![]()

![]() 6

6

NOTE:

•This table saw is provided with a 10 in. diameter blade with a body thickness of 1.8 mm (0.07 in.) thick with a kerf of 2.6 mm (0.1 in.). The riving knife is

2.2 mm (0.09 in.) thick. The blade diameter and the blade body and kerf dimensions must be properly matched with the riving knife thickness.

•The maximum radial distance between the riving knife and the toothed rim of the saw blade is 0.12 in ~ 0.31 in. (3 mm ~ 8 mm)

•The tip of the riving knife shall not be lower than 0.04 in. ~ 0.2 in. (1 mm ~ 5 mm) from the tooth peak.

•The riving knife is thinner than the width of the kerf by approximately 1/64 in. (0.4 mm) on each side.

•The blade body must be thinner than the thickness of the riving knife but the blade kerf must be thicker than the riving knife.

4.Take the blade guard assembly (5) and locate the sliding locking knob (6) on the back of assembly.

5.Insert the blade guard assembly onto the riving knife so that the pin (7) engages into slot (8) completely.

6.Slide the locking knob (6) up and press the guard assembly down so that the entire assembly is flat on the riving knife. Release the locking knob.

7.Make sure that the assembly is locked in place both in front and back.

Fig. GG

5 | 6 7 |

|

7 | 6 | |

8 |

|

|

– 20 –