5.Place a square (D) Fig. 41, on the table and against the saw blade, as shown, and check to see if the blade is square with the table. NOTE: The square should rest between two teeth of the saw blade.

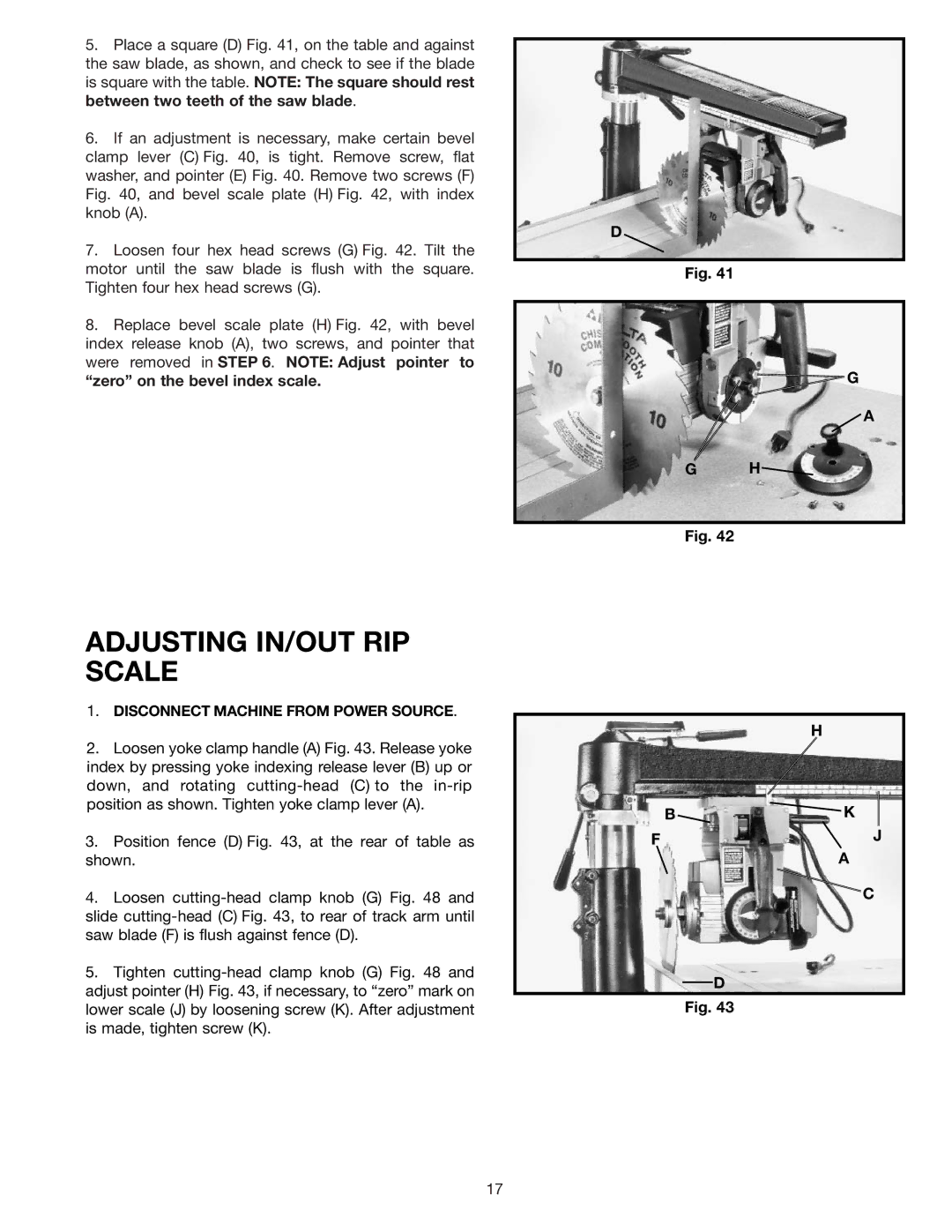

6.If an adjustment is necessary, make certain bevel clamp lever (C) Fig. 40, is tight. Remove screw, flat washer, and pointer (E) Fig. 40. Remove two screws (F) Fig. 40, and bevel scale plate (H) Fig. 42, with index knob (A).

7.Loosen four hex head screws (G) Fig. 42. Tilt the motor until the saw blade is flush with the square. Tighten four hex head screws (G).

8.Replace bevel scale plate (H) Fig. 42, with bevel index release knob (A), two screws, and pointer that were removed in STEP 6. NOTE: Adjust pointer to “zero” on the bevel index scale.

ADJUSTING IN/OUT RIP SCALE

1.DISCONNECT MACHINE FROM POWER SOURCE.

2.Loosen yoke clamp handle (A) Fig. 43. Release yoke index by pressing yoke indexing release lever (B) up or down, and rotating

3.Position fence (D) Fig. 43, at the rear of table as shown.

4.Loosen

5.Tighten

D

Fig. 41

![]() G

G

![]() A

A

GH![]()

Fig. 42

H

B ![]()

![]() K

K

FJ A

C

D

Fig. 43

17