SPECIAL ADJUSTMENTS

|

| Paper Near End Sensor |

| ||

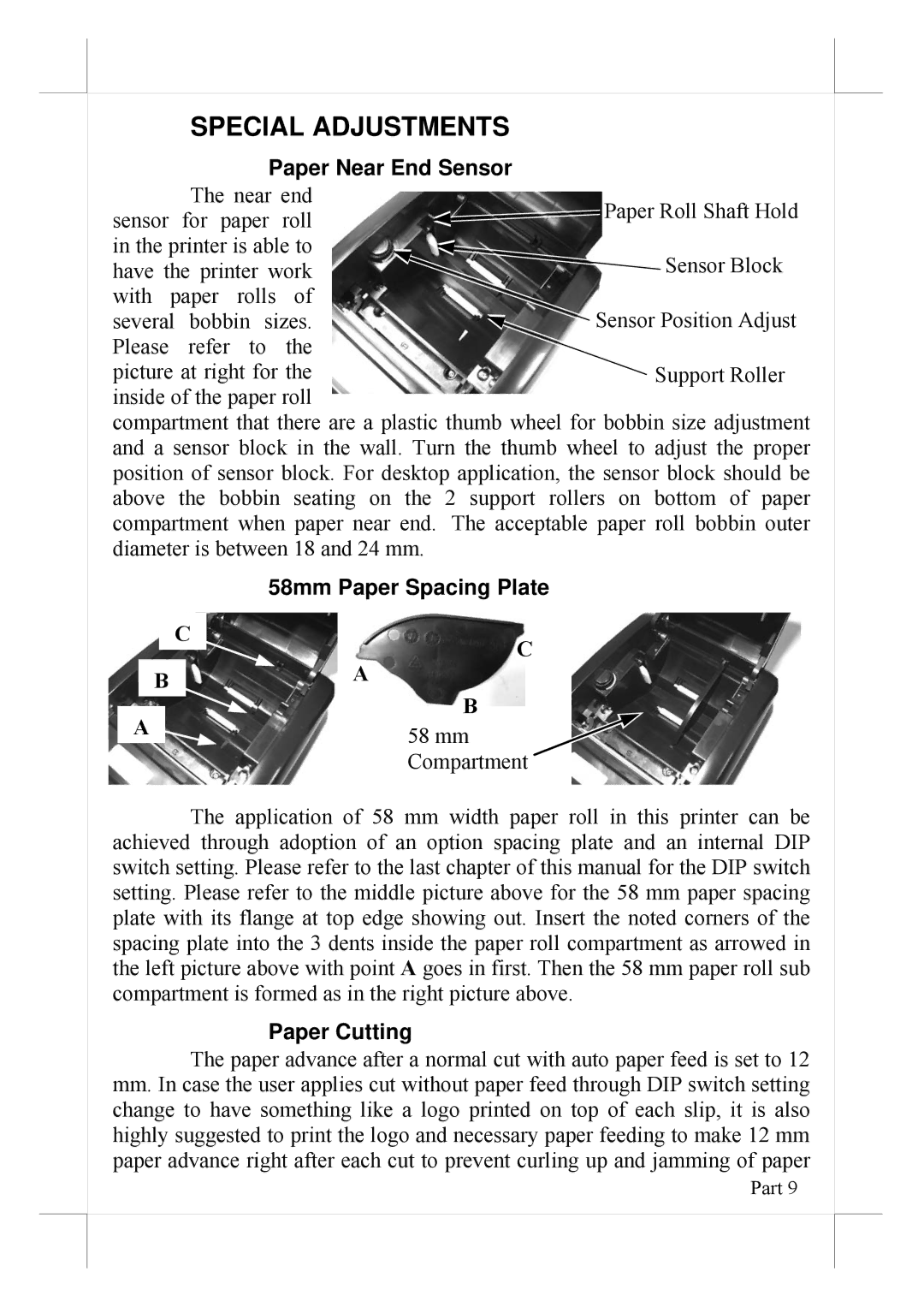

| The near end | Paper Roll Shaft Hold | |||

sensor | for paper | roll | |||

| |||||

in the printer is able to | Sensor Block | ||||

have the printer work | |||||

with paper | rolls | of | Sensor Position Adjust | ||

several | bobbin sizes. | ||||

Please | refer | to | the |

| |

picture at right for the | Support Roller | ||||

inside of the paper roll |

| ||||

compartment that there are a plastic thumb wheel for bobbin size adjustment and a sensor block in the wall. Turn the thumb wheel to adjust the proper position of sensor block. For desktop application, the sensor block should be above the bobbin seating on the 2 support rollers on bottom of paper compartment when paper near end.. The acceptable paper roll bobbin outer diameter is between 18 and 24 mm.

58mm Paper Spacing Plate

C

C

BA

| B | |

A | ||

58 mm | ||

| ||

| Compartment |

The application of 58 mm width paper roll in this printer can be achieved through adoption of an option spacing plate and an internal DIP switch setting. Please refer to the last chapter of this manual for the DIP switch setting. Please refer to the middle picture above for the 58 mm paper spacing plate with its flange at top edge showing out. Insert the noted corners of the spacing plate into the 3 dents inside the paper roll compartment as arrowed in the left picture above with point A goes in first. Then the 58 mm paper roll sub compartment is formed as in the right picture above.

Paper Cutting

The paper advance after a normal cut with auto paper feed is set to 12

mm.In case the user applies cut without paper feed through DIP switch setting change to have something like a logo printed on top of each slip, it is also highly suggested to print the logo and necessary paper feeding to make 12 mm paper advance right after each cut to prevent curling up and jamming of paper

Part 9