Spindle Gib Adjustment

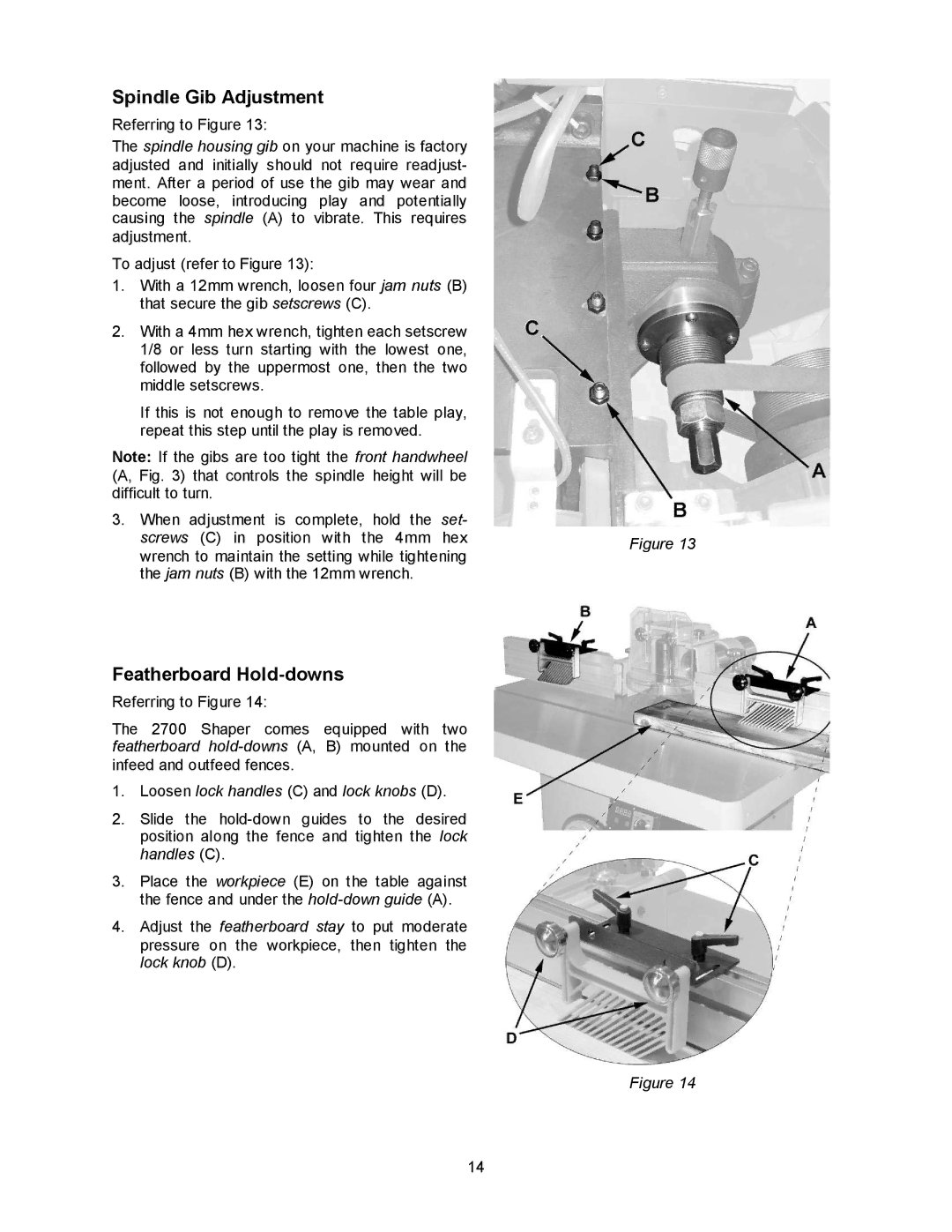

Referring to Figure 13:

The spindle housing gib on your machine is factory adjusted and initially should not require readjust- ment. After a period of use the gib may wear and become loose, introducing play and potentially causing the spindle (A) to vibrate. This requires adjustment.

To adjust (refer to Figure 13):

1.With a 12mm wrench, loosen four jam nuts (B) that secure the gib setscrews (C).

2.With a 4mm hex wrench, tighten each setscrew 1/8 or less turn starting with the lowest one, followed by the uppermost one, then the two middle setscrews.

If this is not enough to remove the table play, repeat this step until the play is removed.

Note: If the gibs are too tight the front handwheel (A, Fig. 3) that controls the spindle height will be difficult to turn.

3.When adjustment is complete, hold the set- screws (C) in position with the 4mm hex wrench to maintain the setting while tightening the jam nuts (B) with the 12mm wrench.

Featherboard Hold-downs

Referring to Figure 14:

The 2700 Shaper comes equipped with two featherboard

1.Loosen lock handles (C) and lock knobs (D).

2.Slide the

3.Place the workpiece (E) on the table against the fence and under the

4.Adjust the featherboard stay to put moderate pressure on the workpiece, then tighten the lock knob (D).

Figure 13

Figure 14

14