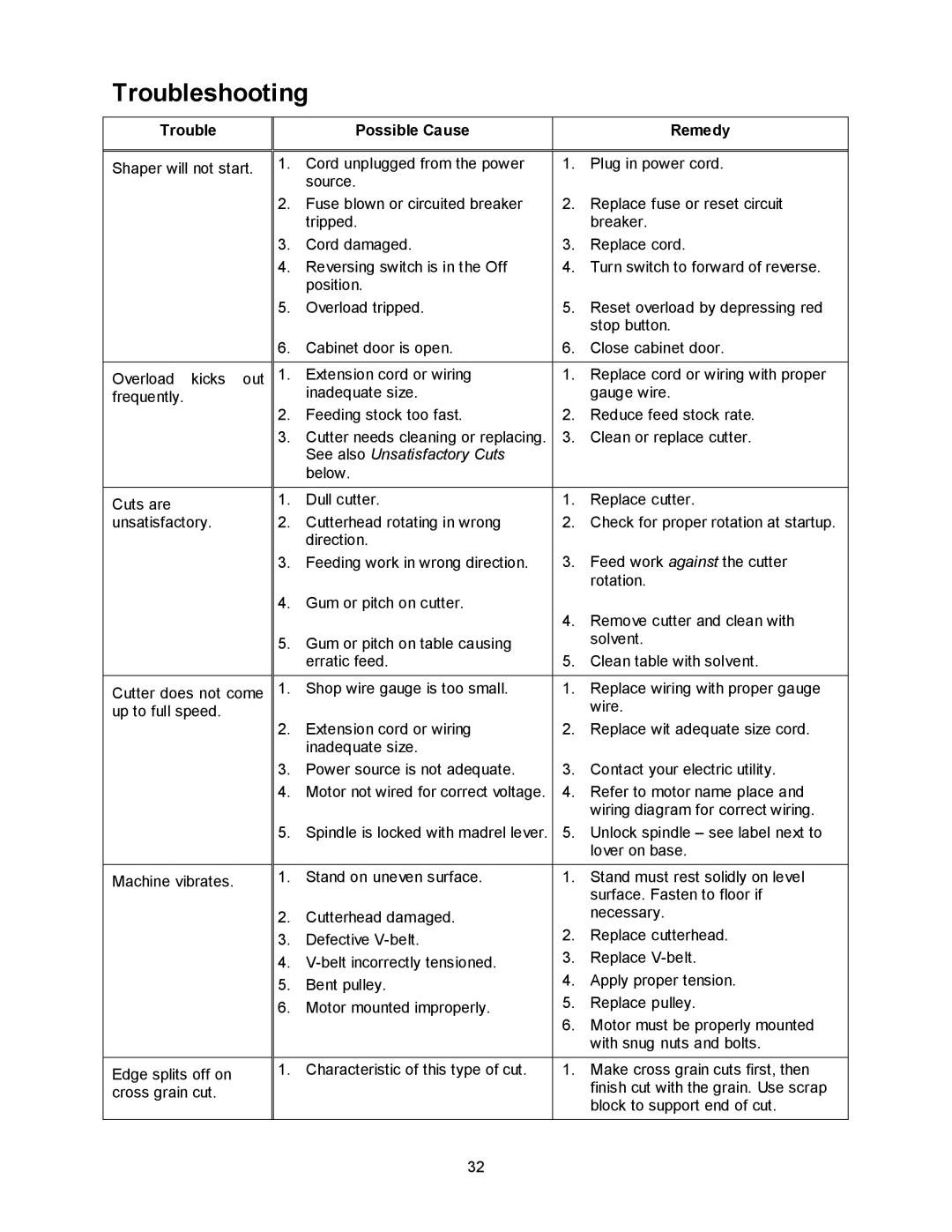

Troubleshooting

Trouble

Shaper will not start.

Overload kicks out frequently.

Cuts are unsatisfactory.

Cutter does not come up to full speed.

Machine vibrates.

Edge splits off on cross grain cut.

| Possible Cause |

| Remedy |

|

|

|

|

|

|

|

|

1. | Cord unplugged from the power | 1. | Plug in power cord. |

| source. |

|

|

2. | Fuse blown or circuited breaker | 2. | Replace fuse or reset circuit |

| tripped. |

| breaker. |

3. | Cord damaged. | 3. | Replace cord. |

4. | Reversing switch is in the Off | 4. | Turn switch to forward of reverse. |

| position. |

|

|

5. | Overload tripped. | 5. | Reset overload by depressing red |

|

|

| stop button. |

6. | Cabinet door is open. | 6. | Close cabinet door. |

|

|

|

|

1. | Extension cord or wiring | 1. | Replace cord or wiring with proper |

| inadequate size. |

| gauge wire. |

2. | Feeding stock too fast. | 2. | Reduce feed stock rate. |

3. | Cutter needs cleaning or replacing. | 3. Clean or replace cutter. | |

| See also Unsatisfactory Cuts |

|

|

| below. |

|

|

|

|

|

|

1. | Dull cutter. | 1. | Replace cutter. |

2. | Cutterhead rotating in wrong | 2. | Check for proper rotation at startup. |

| direction. |

|

|

3. | Feeding work in wrong direction. | 3. | Feed work against the cutter |

|

|

| rotation. |

4. | Gum or pitch on cutter. | 4. | Remove cutter and clean with |

|

| ||

5. | Gum or pitch on table causing |

| solvent. |

| erratic feed. | 5. | Clean table with solvent. |

|

|

|

|

1. | Shop wire gauge is too small. | 1. | Replace wiring with proper gauge |

|

|

| wire. |

2. | Extension cord or wiring | 2. | Replace wit adequate size cord. |

| inadequate size. |

|

|

3. | Power source is not adequate. | 3. | Contact your electric utility. |

4. | Motor not wired for correct voltage. | 4. Refer to motor name place and | |

|

|

| wiring diagram for correct wiring. |

5. | Spindle is locked with madrel lever. | 5. Unlock spindle – see label next to | |

|

|

| lover on base. |

|

|

|

|

1. | Stand on uneven surface. | 1. | Stand must rest solidly on level |

|

|

| surface. Fasten to floor if |

2. | Cutterhead damaged. |

| necessary. |

3. | Defective | 2. | Replace cutterhead. |

4. | 3. | Replace | |

5. | Bent pulley. | 4. | Apply proper tension. |

6. | Motor mounted improperly. | 5. | Replace pulley. |

|

| 6. | Motor must be properly mounted |

|

|

| with snug nuts and bolts. |

|

|

|

|

1. | Characteristic of this type of cut. | 1. | Make cross grain cuts first, then |

|

|

| finish cut with the grain. Use scrap |

|

|

| block to support end of cut. |

|

|

|

|

32