Operations

Overview

Before applying power to the machine, Check the motor and switch wiring diagrams for proper voltage connections. Check that all mounting screws and bolts are tight.

Turn on the motor momentarily to check for proper rotation. The spindle should rotate counterclock- wise when looking down on the spindle. Correct as required.

Run the machine for a short period of time to ensure that the moving parts are working properly with no excessive vibration. If a problem develops, correct it before turning the shaper over for general use.

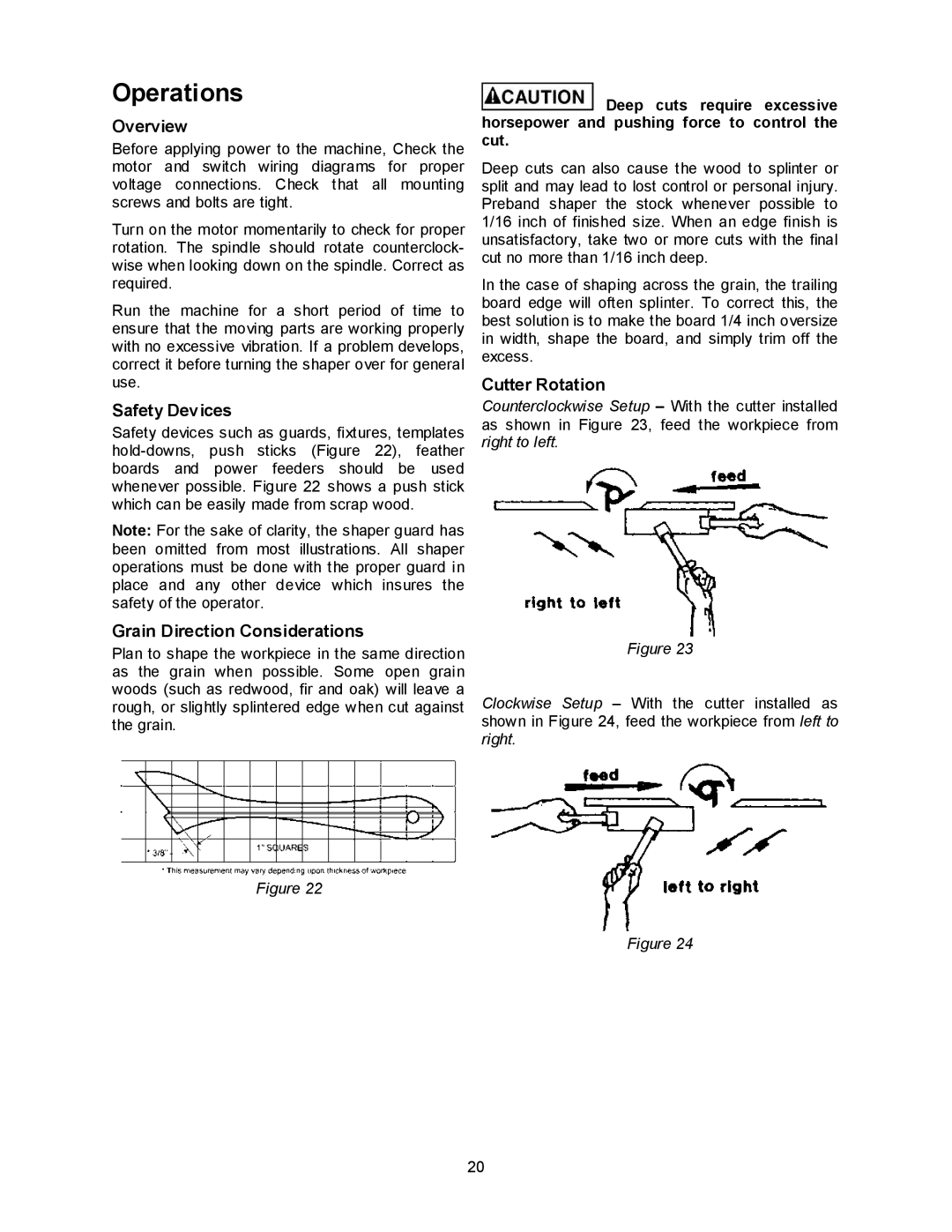

Safety Devices

Safety devices such as guards, fixtures, templates

Note: For the sake of clarity, the shaper guard has been omitted from most illustrations. All shaper operations must be done with the proper guard in place and any other device which insures the safety of the operator.

Grain Direction Considerations

Plan to shape the workpiece in the same direction as the grain when possible. Some open grain woods (such as redwood, fir and oak) will leave a rough, or slightly splintered edge when cut against the grain.

Figure 22

![]() Deep cuts require excessive horsepower and pushing force to control the cut.

Deep cuts require excessive horsepower and pushing force to control the cut.

Deep cuts can also cause the wood to splinter or split and may lead to lost control or personal injury. Preband shaper the stock whenever possible to 1/16 inch of finished size. When an edge finish is unsatisfactory, take two or more cuts with the final cut no more than 1/16 inch deep.

In the case of shaping across the grain, the trailing board edge will often splinter. To correct this, the best solution is to make the board 1/4 inch oversize in width, shape the board, and simply trim off the excess.

Cutter Rotation

Counterclockwise Setup – With the cutter installed as shown in Figure 23, feed the workpiece from right to left.

Figure 23

Clockwise Setup – With the cutter installed as shown in Figure 24, feed the workpiece from left to right.

Figure 24

20