Cleaning

Exposed metal surfaces, such as the table top and extension wings, have been given a protective coating at the factory. This should be removed with a soft cloth moistened with kerosene. Do not use acetone, gasoline, or lacquer thinner for this purpose. Do not use solvents on plastic parts, and do not use an abrasive pad because it may scratch the surfaces.

Assembly

Mounting the Fence

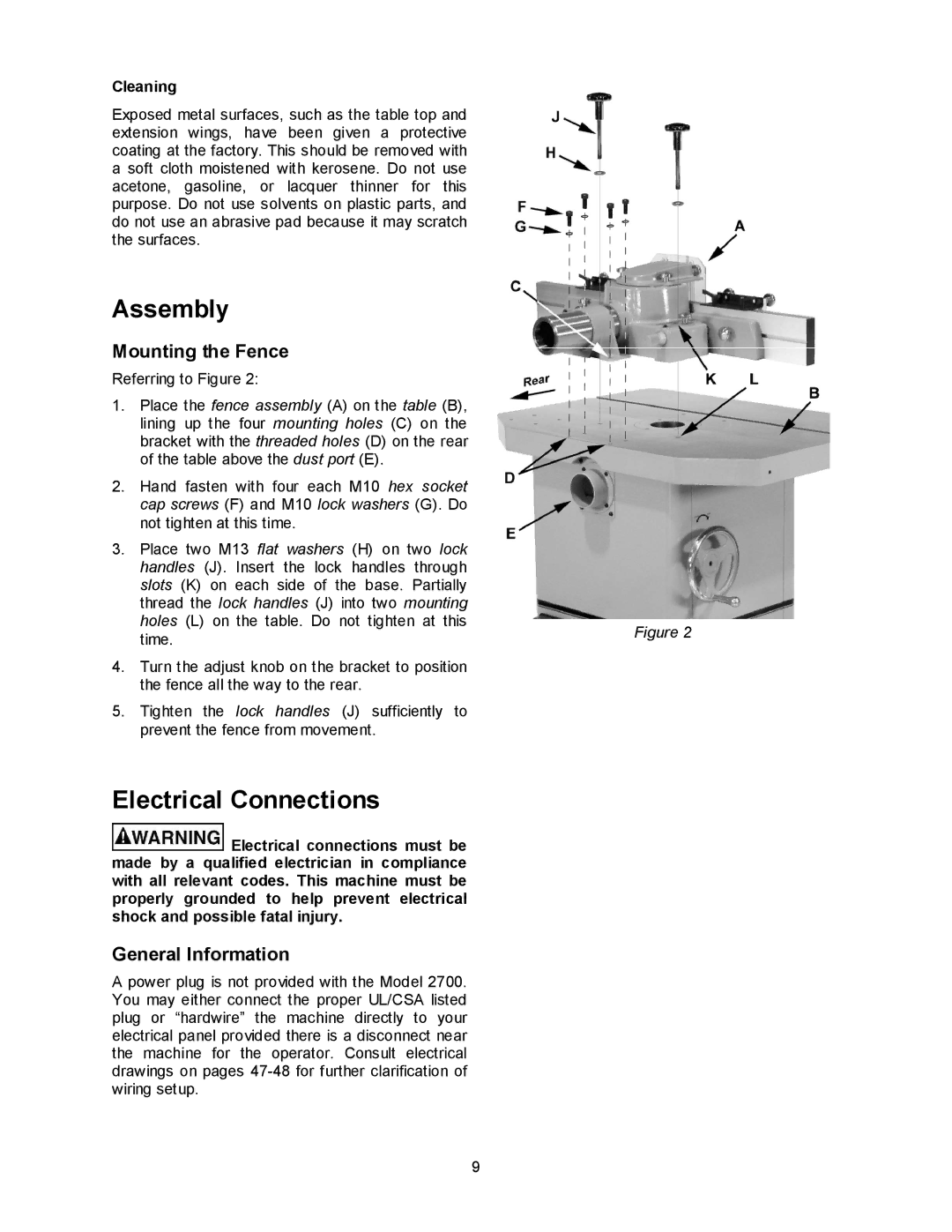

Referring to Figure 2:

1. Place the fence assembly (A) on the table (B), lining up the four mounting holes (C) on the bracket with the threaded holes (D) on the rear of the table above the dust port (E).

2. Hand fasten with four each M10 hex socket cap screws (F) and M10 lock washers (G). Do not tighten at this time.

3. Place two M13 flat washers (H) on two lock handles (J). Insert the lock handles through slots (K) on each side of the base. Partially thread the lock handles (J) into two mounting

holes (L) on the table. Do not tighten at this | Figure 2 | |

time. | ||

|

4.Turn the adjust knob on the bracket to position the fence all the way to the rear.

5.Tighten the lock handles (J) sufficiently to prevent the fence from movement.

Electrical Connections

![]() Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

Electrical connections must be made by a qualified electrician in compliance with all relevant codes. This machine must be properly grounded to help prevent electrical shock and possible fatal injury.

General Information

A power plug is not provided with the Model 2700. You may either connect the proper UL/CSA listed plug or “hardwire” the machine directly to your electrical panel provided there is a disconnect near the machine for the operator. Consult electrical drawings on pages

9