Edge Shaping

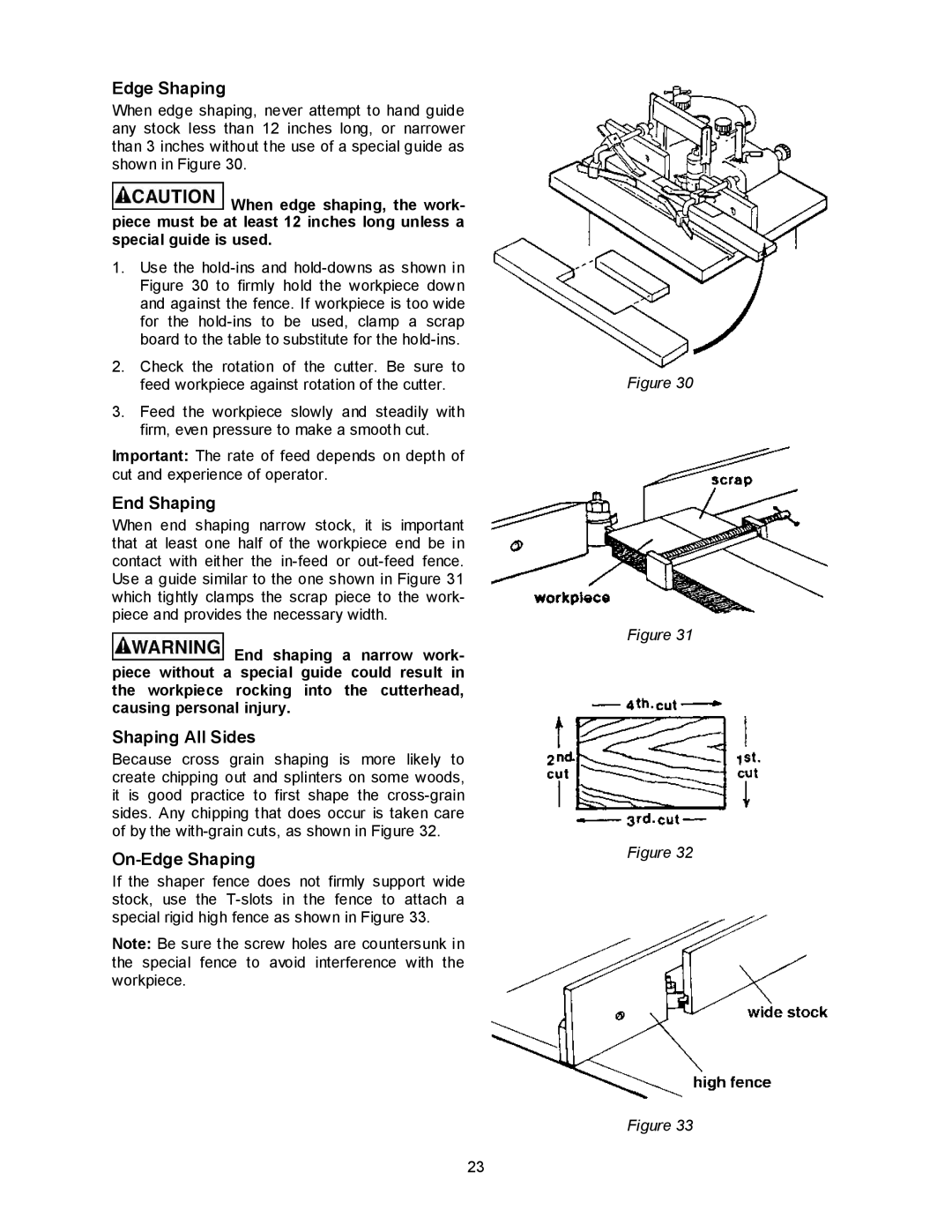

When edge shaping, never attempt to hand guide any stock less than 12 inches long, or narrower than 3 inches without the use of a special guide as shown in Figure 30.

![]() When edge shaping, the work- piece must be at least 12 inches long unless a special guide is used.

When edge shaping, the work- piece must be at least 12 inches long unless a special guide is used.

1.Use the

2.Check the rotation of the cutter. Be sure to feed workpiece against rotation of the cutter.

3.Feed the workpiece slowly and steadily with firm, even pressure to make a smooth cut.

Important: The rate of feed depends on depth of cut and experience of operator.

End Shaping

When end shaping narrow stock, it is important that at least one half of the workpiece end be in contact with either the

![]() End shaping a narrow work- piece without a special guide could result in the workpiece rocking into the cutterhead, causing personal injury.

End shaping a narrow work- piece without a special guide could result in the workpiece rocking into the cutterhead, causing personal injury.

Shaping All Sides

Because cross grain shaping is more likely to create chipping out and splinters on some woods, it is good practice to first shape the

On-Edge Shaping

If the shaper fence does not firmly support wide stock, use the

Note: Be sure the screw holes are countersunk in the special fence to avoid interference with the workpiece.

Figure 30

Figure 31

Figure 32

Figure 33

23