|

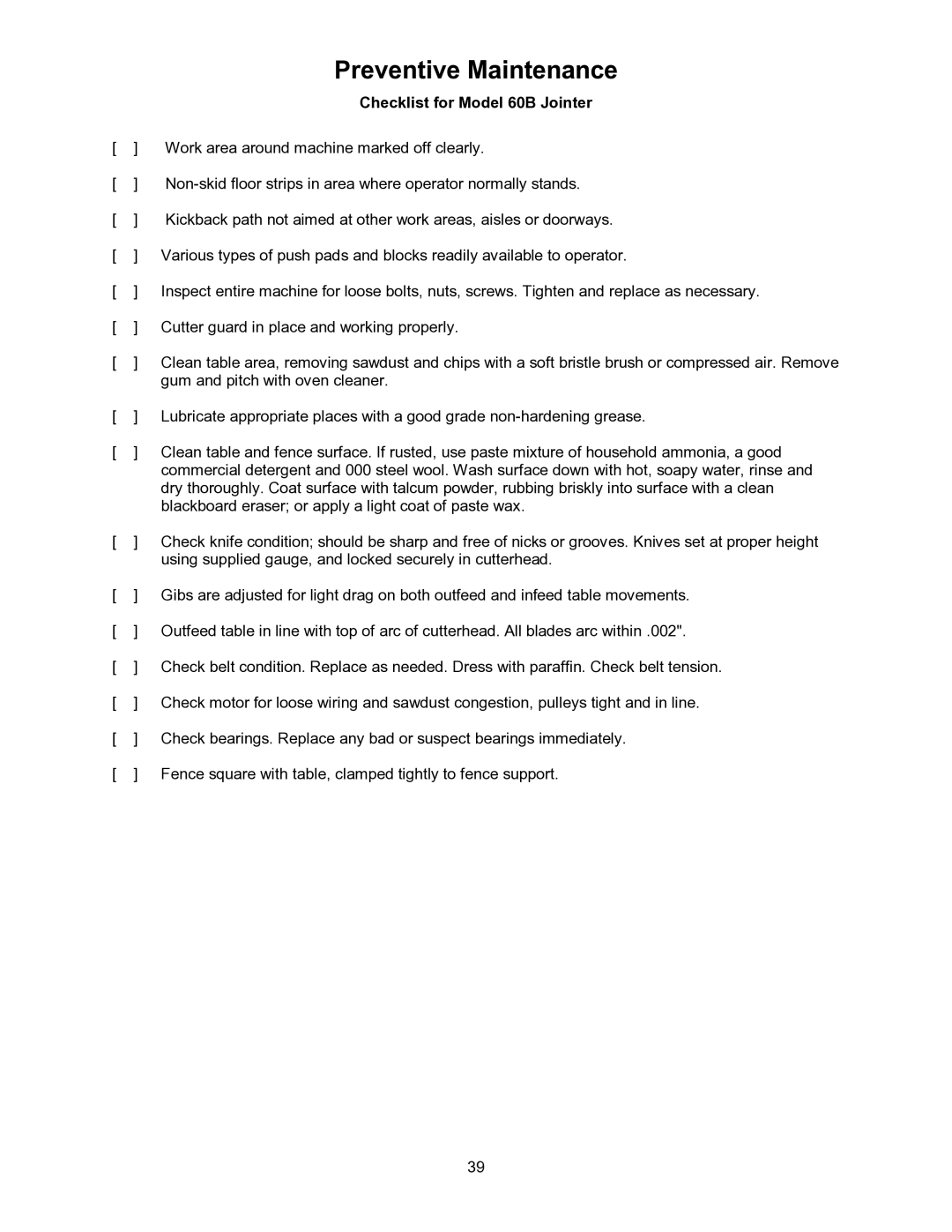

| Preventive Maintenance |

|

| Checklist for Model 60B Jointer |

[ | ] | Work area around machine marked off clearly. |

[ | ] | |

[ | ] | Kickback path not aimed at other work areas, aisles or doorways. |

[ | ] | Various types of push pads and blocks readily available to operator. |

[ | ] | Inspect entire machine for loose bolts, nuts, screws. Tighten and replace as necessary. |

[ | ] | Cutter guard in place and working properly. |

[ | ] | Clean table area, removing sawdust and chips with a soft bristle brush or compressed air. Remove |

|

| gum and pitch with oven cleaner. |

[ | ] | Lubricate appropriate places with a good grade |

[ | ] | Clean table and fence surface. If rusted, use paste mixture of household ammonia, a good |

|

| commercial detergent and 000 steel wool. Wash surface down with hot, soapy water, rinse and |

|

| dry thoroughly. Coat surface with talcum powder, rubbing briskly into surface with a clean |

|

| blackboard eraser; or apply a light coat of paste wax. |

[ | ] | Check knife condition; should be sharp and free of nicks or grooves. Knives set at proper height |

|

| using supplied gauge, and locked securely in cutterhead. |

[ | ] | Gibs are adjusted for light drag on both outfeed and infeed table movements. |

[ | ] | Outfeed table in line with top of arc of cutterhead. All blades arc within .002". |

[ | ] | Check belt condition. Replace as needed. Dress with paraffin. Check belt tension. |

[ | ] | Check motor for loose wiring and sawdust congestion, pulleys tight and in line. |

[ | ] | Check bearings. Replace any bad or suspect bearings immediately. |

[ | ] | Fence square with table, clamped tightly to fence support. |

39