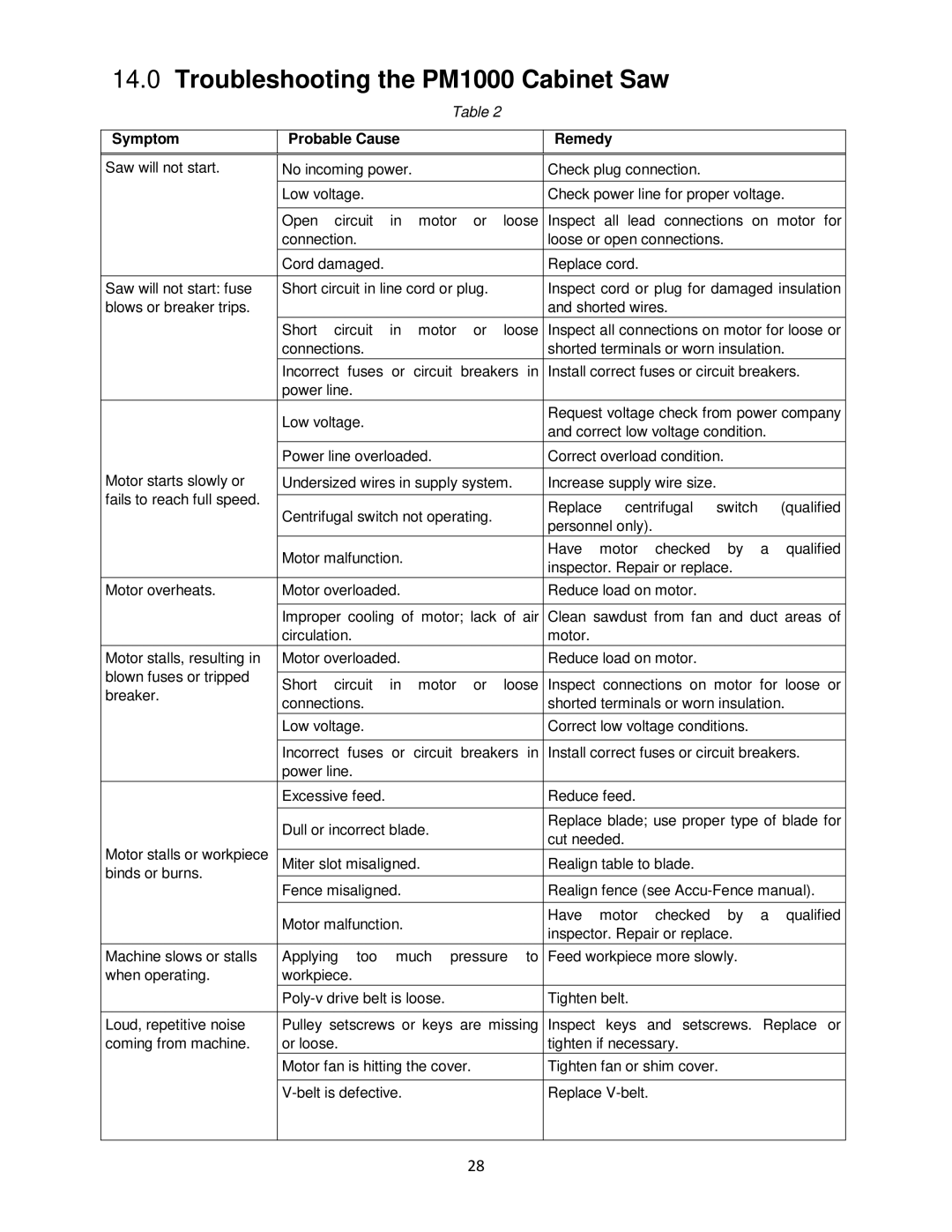

14.0Troubleshooting the PM1000 Cabinet Saw

Table 2

Symptom | Probable Cause | Remedy |

|

|

|

| ||

Saw will not start. | No incoming power. | Check plug connection. |

|

|

| |||

| Low voltage. | Check power line for proper voltage. | ||||||

|

|

| ||||||

| Open circuit in motor or loose | Inspect all lead connections on motor for | ||||||

| connection. | loose or open connections. |

|

| ||||

| Cord damaged. | Replace cord. |

|

|

|

| ||

Saw will not start: fuse | Short circuit in line cord or plug. | Inspect cord or plug for damaged insulation | ||||||

blows or breaker trips. |

| and shorted wires. |

|

|

| |||

| Short circuit in motor or loose | Inspect all connections on motor for loose or | ||||||

| connections. | shorted terminals or worn insulation. | ||||||

| Incorrect fuses or circuit breakers in | Install correct fuses or circuit breakers. | ||||||

| power line. |

|

|

|

|

|

| |

| Low voltage. | Request voltage check from power company | ||||||

| and correct low voltage condition. |

| ||||||

|

|

| ||||||

| Power line overloaded. | Correct overload condition. |

|

| ||||

Motor starts slowly or |

|

|

|

|

| |||

Undersized wires in supply system. | Increase supply wire size. |

|

|

| ||||

fails to reach full speed. |

|

|

|

|

|

|

| |

Centrifugal switch not operating. | Replace centrifugal | switch |

| (qualified | ||||

|

| |||||||

| personnel only). |

|

|

|

| |||

|

|

|

|

|

| |||

| Motor malfunction. | Have | motor | checked | by | a | qualified | |

| inspector. Repair or replace. |

|

| |||||

|

|

|

| |||||

Motor overheats. | Motor overloaded. | Reduce load on motor. |

|

|

| |||

|

|

| ||||||

| Improper cooling of motor; lack of air | Clean sawdust from fan and duct areas of | ||||||

| circulation. | motor. |

|

|

|

|

| |

Motor stalls, resulting in | Motor overloaded. | Reduce load on motor. |

|

|

| |||

blown fuses or tripped |

|

|

|

|

|

|

| |

Short circuit in motor or loose | Inspect | connections on motor | for | loose or | ||||

breaker. | ||||||||

connections. | shorted terminals or worn insulation. | |||||||

| ||||||||

| Low voltage. | Correct low voltage conditions. |

|

| ||||

|

|

| ||||||

| Incorrect fuses or circuit breakers in | Install correct fuses or circuit breakers. | ||||||

| power line. |

|

|

|

|

|

| |

| Excessive feed. | Reduce feed. |

|

|

|

| ||

| Dull or incorrect blade. | Replace blade; use proper type of blade for | ||||||

| cut needed. |

|

|

|

| |||

Motor stalls or workpiece |

|

|

|

|

| |||

Miter slot misaligned. | Realign table to blade. |

|

|

| ||||

binds or burns. |

|

|

|

|

|

|

| |

Fence misaligned. | Realign fence (see | |||||||

| ||||||||

|

|

|

|

|

|

|

| |

| Motor malfunction. | Have | motor | checked | by | a | qualified | |

| inspector. Repair or replace. |

|

| |||||

|

|

|

| |||||

Machine slows or stalls | Applying too much pressure to | Feed workpiece more slowly. |

|

| ||||

when operating. | workpiece. |

|

|

|

|

|

| |

| Tighten belt. |

|

|

|

| |||

|

|

| ||||||

Loud, repetitive noise | Pulley setscrews or keys are missing | Inspect keys and setscrews. Replace or | ||||||

coming from machine. | or loose. | tighten if necessary. |

|

|

| |||

| Motor fan is hitting the cover. | Tighten fan or shim cover. |

|

| ||||

|

|

|

|

|

|

| ||

| Replace |

|

|

|

| |||

|

|

|

|

|

|

|

| |

28