9.4Platen Position

The sander has a removable platen with a graphite strip and a felt pad to reduce friction against the sanding belt. Positioning of the platen depends upon the type of wood being used.

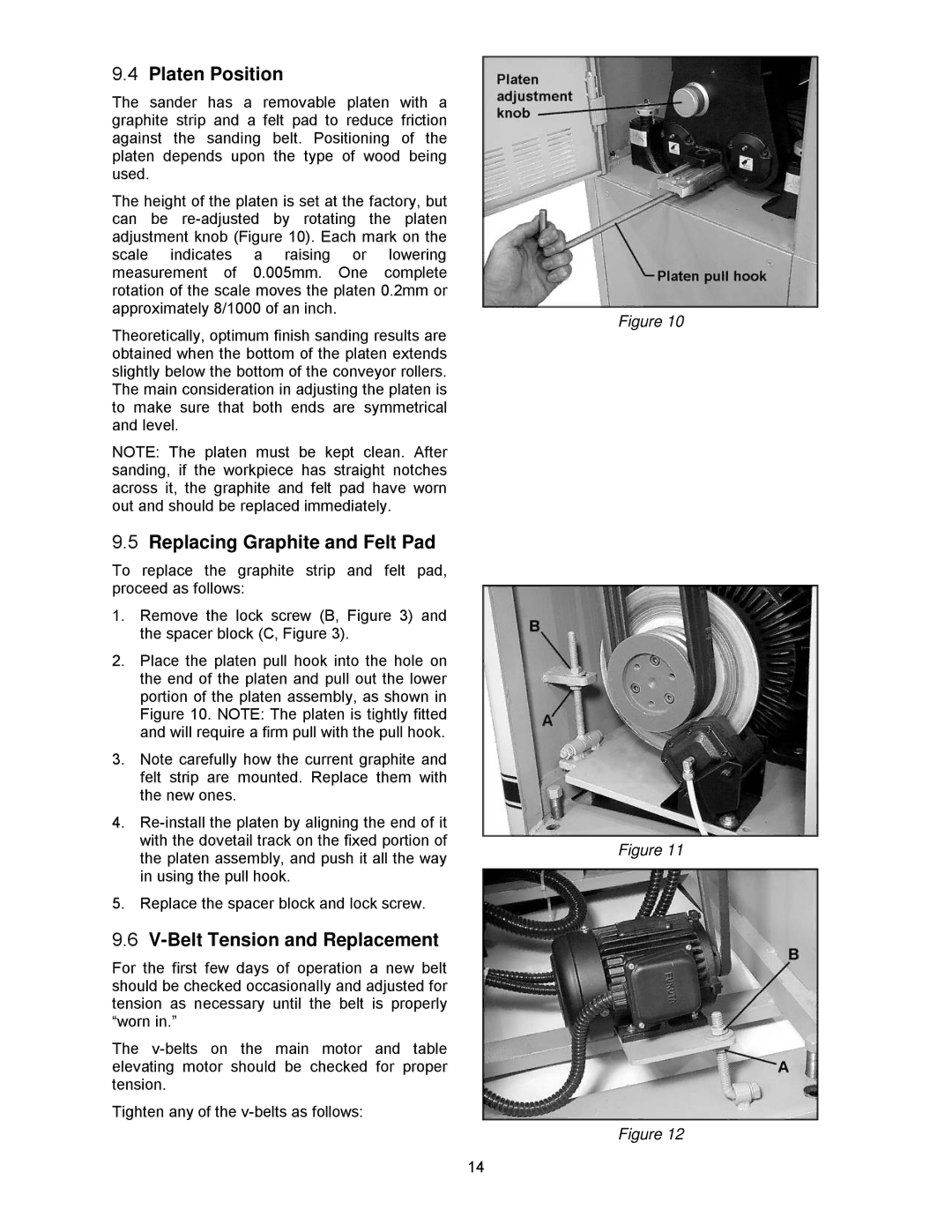

The height of the platen is set at the factory, but can be

Theoretically, optimum finish sanding results are obtained when the bottom of the platen extends slightly below the bottom of the conveyor rollers. The main consideration in adjusting the platen is to make sure that both ends are symmetrical and level.

NOTE: The platen must be kept clean. After sanding, if the workpiece has straight notches across it, the graphite and felt pad have worn out and should be replaced immediately.

9.5Replacing Graphite and Felt Pad

To replace the graphite strip and felt pad, proceed as follows:

1.Remove the lock screw (B, Figure 3) and the spacer block (C, Figure 3).

2.Place the platen pull hook into the hole on the end of the platen and pull out the lower portion of the platen assembly, as shown in Figure 10. NOTE: The platen is tightly fitted and will require a firm pull with the pull hook.

3.Note carefully how the current graphite and felt strip are mounted. Replace them with the new ones.

4.

5.Replace the spacer block and lock screw.

9.6V-Belt Tension and Replacement

For the first few days of operation a new belt should be checked occasionally and adjusted for tension as necessary until the belt is properly “worn in.”

The

Tighten any of the

Figure 10

Figure 11

Figure 12

14