If the sanding belt breaks, all movement will be stopped, though the conveyor table can still be raised or lowered.

Once the machine has stopped, the operator should find where the braking system was tripped, and make the necessary adjustments. The machine can then be

12.0Maintenance

![]() Before doing any maintenance on the sander, disconnect it from the electrical supply by pulling out the plug or switching off the main switch. Failure to comply may cause serious injury.

Before doing any maintenance on the sander, disconnect it from the electrical supply by pulling out the plug or switching off the main switch. Failure to comply may cause serious injury.

The interior of the machine should be thoroughly cleaned each day after using the sander. Remove the sanding belt before cleaning and

Keep the sanding belt clean using cleaning sticks or pads (not provided).

Blow dust off the conveyor belt with compressed air or use a dust collector vacuum attachment.

The bearings should be greased after every 150 work hours.

13.0Dust Port Layout

The water should be removed daily from inside the filter cups. On the filter/regulator at the back of the cabinet, press the drain cock (see Figure 2). On the filter inside the cabinet, unscrew the cup to empty it.

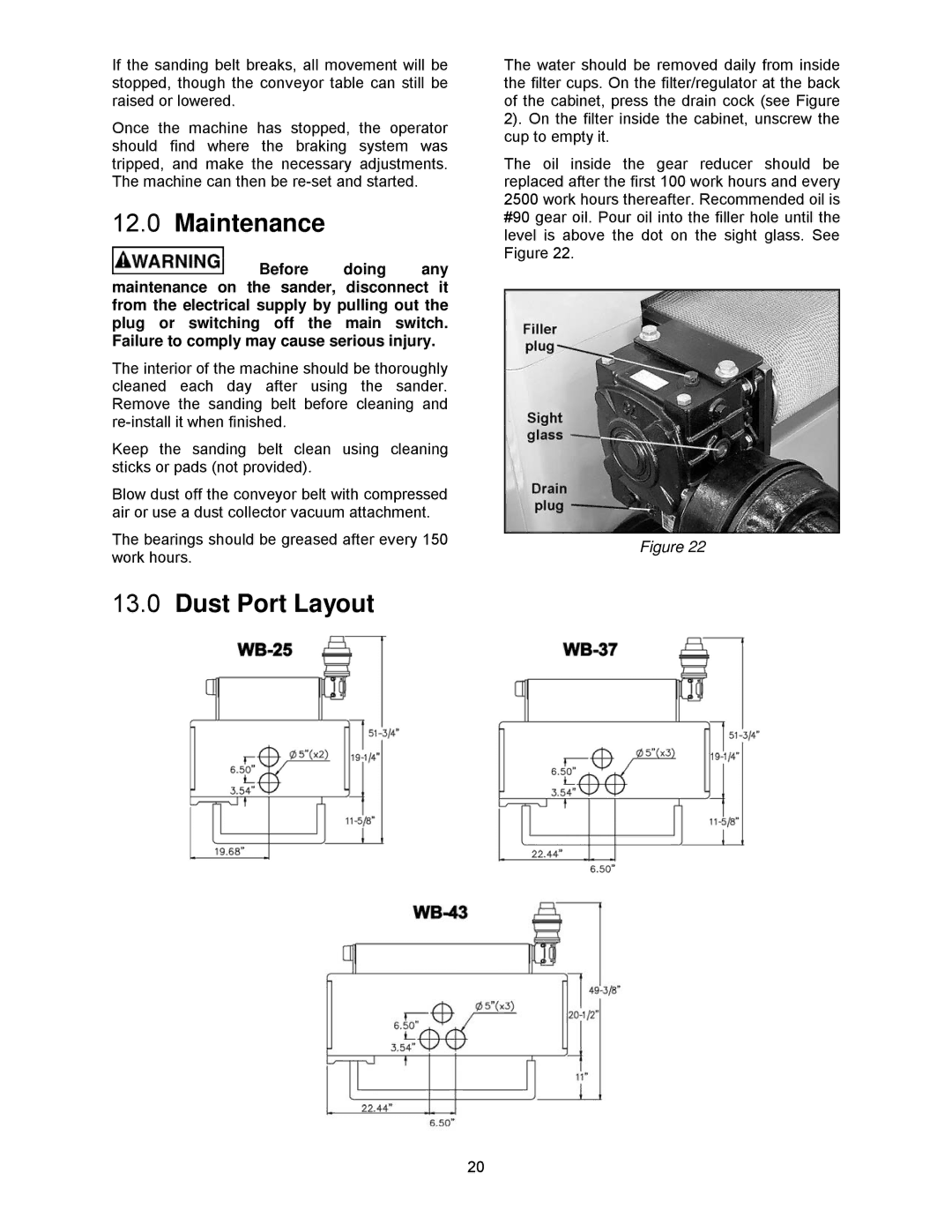

The oil inside the gear reducer should be replaced after the first 100 work hours and every 2500 work hours thereafter. Recommended oil is #90 gear oil. Pour oil into the filler hole until the level is above the dot on the sight glass. See Figure 22.

Figure 22

20